midcap

Pattern Altitude

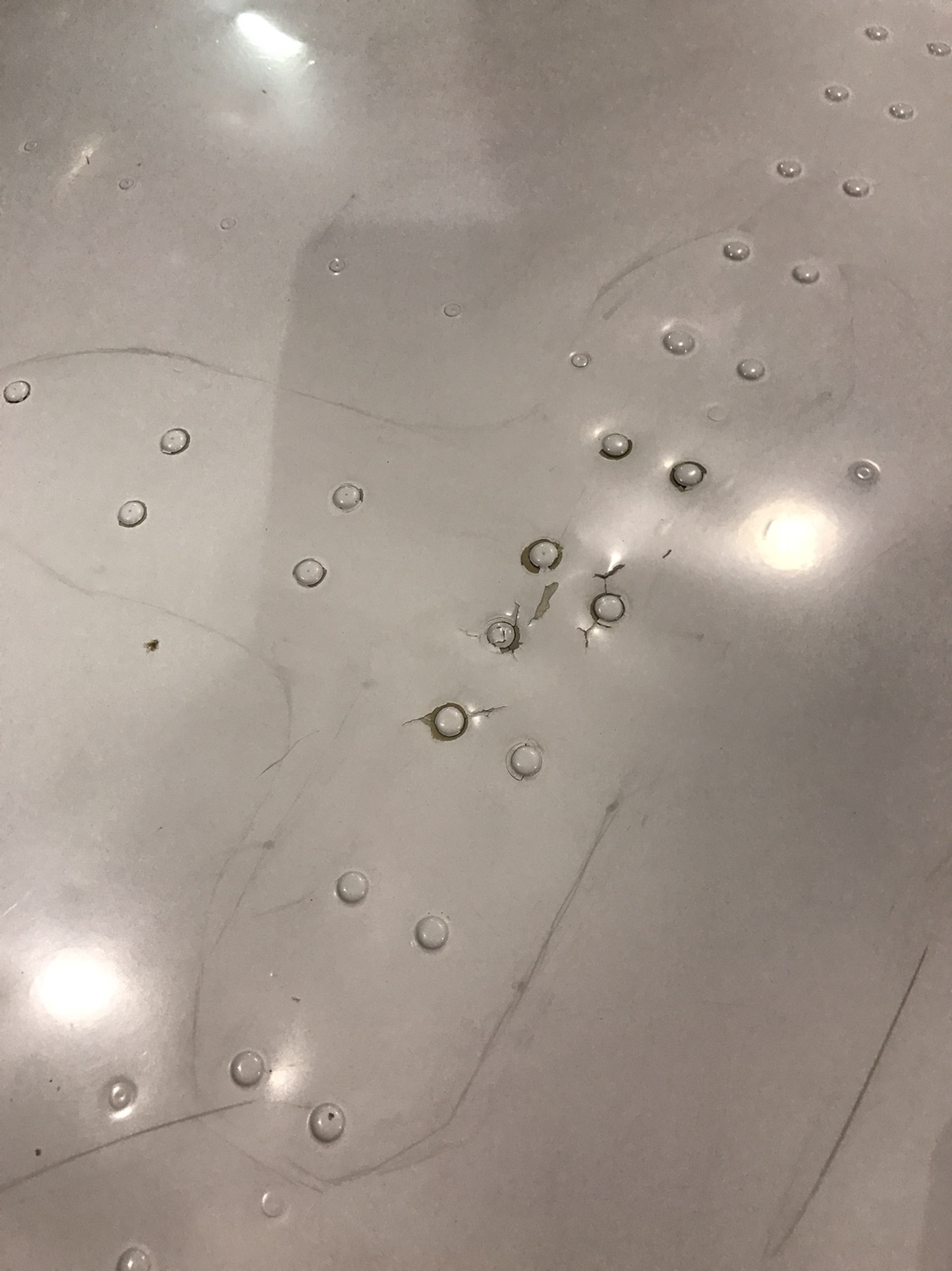

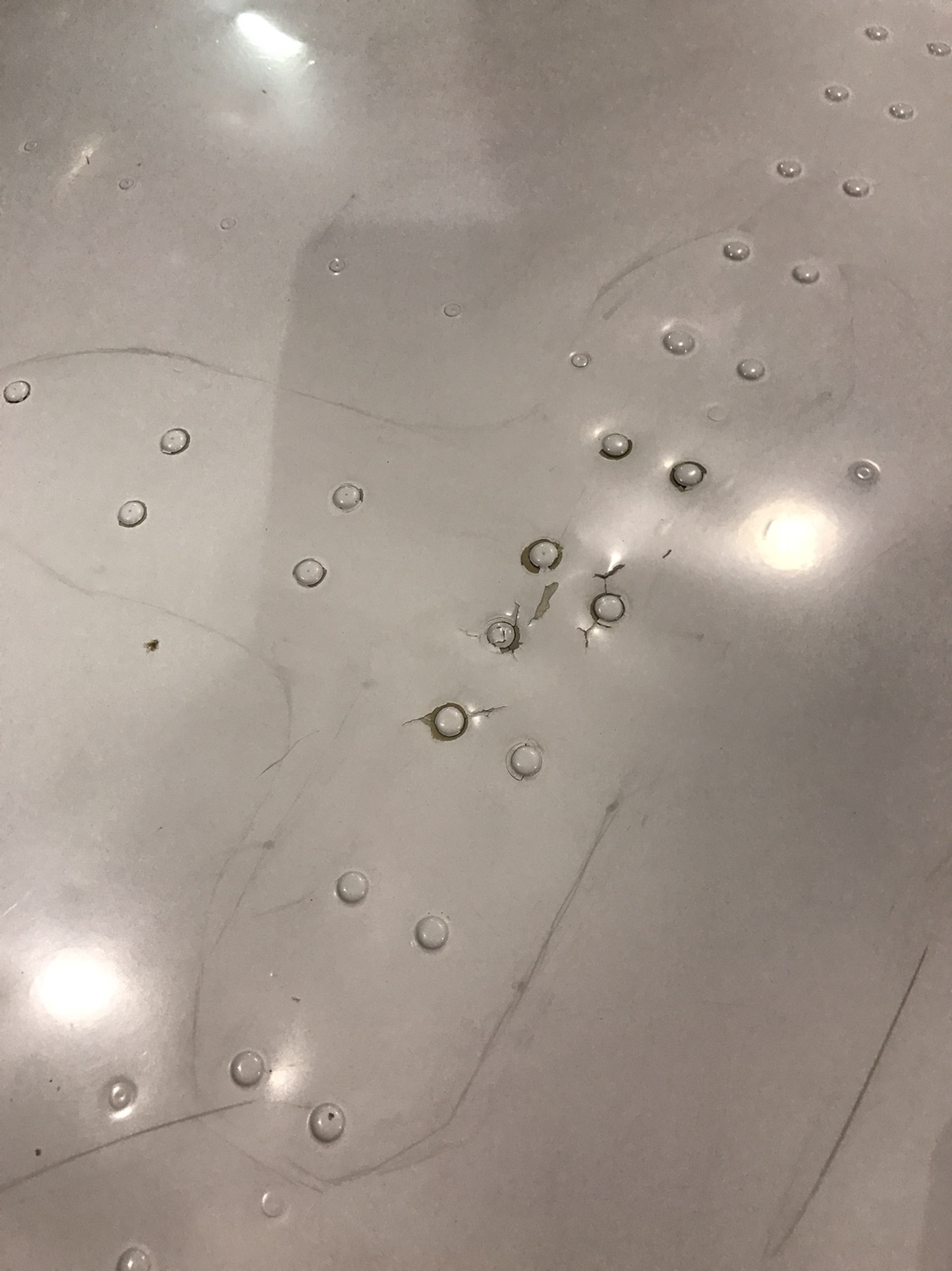

ouchWhen metal is visibly distorted after a landing, that’s a good indication.

This is the right wing of an Arrow just above the landing gear.

ouchWhen metal is visibly distorted after a landing, that’s a good indication.

This is the right wing of an Arrow just above the landing gear.

Not flying an ERAU Arrow, nor do I think I will be. But if I were I would like to know it had been inspected for these cracks.

FIFY.

...and i agree, i wouldn't rent an ERAU arrow either. so yeah, have THEM incur the cost of their own dereliction, instead of subrogating it to me. i thought this was personal responsibility, puritan work ethic no social net of consequence America. oooh you mean deep pockets get the carve out darling treatment? well golly gee, color me naive.

If that sweatshop was flying Bos and they flew a wing off one, you'd see the same nonsense panic befall the cheap seat pharisees on here. But boy would the sparks fly if you told beech owners their personally owned 33/35/36 was a death trap because ERAU broke one. you havent seen mouth frothing tribalism quite like the bonanza cult. cherokee owners are frankly kindergarteners compared to these folks on that account.

at any rate, my point with that is, I dont care if you never fly a pa28, but dont legislate my purview with your panic. thats ultimately my only dog in this fight. i would feel the same way if they were picking on cessnas or beech products. its about holding erau accountable for their behavior, instead of paying off the hall monitor so we all get to wear diapers because our pockets are small.

I am not disagreeing with you in the slightest. But a few things need to be clarified. Is this a problem that extends beyond ERAU? Are other training Arrows owned by other schools showing similar problems?FIFY.

...and i agree, i wouldn't rent an ERAU arrow either. so yeah, have THEM incur the cost of their own dereliction, instead of subrogating it to me. i thought this was personal responsibility, puritan work ethic no social net of consequence America. oooh you mean deep pockets get the carve out darling treatment? well golly gee, color me naive.

If that sweatshop was flying Bos and they flew a wing off one, you'd see the same nonsense panic befall the cheap seat pharisees on here. But boy would the sparks fly if you told beech owners their personally owned 33/35/36 was a death trap because ERAU broke one. you havent seen mouth frothing tribalism quite like the bonanza cult. cherokee owners are frankly kindergarteners compared to these folks on that account.

at any rate, my point with that is, I dont care if you never fly a pa28, but dont legislate my purview with your panic. thats ultimately my only dog in this fight. i would feel the same way if they were picking on cessnas or beech products. its about holding erau accountable for their behavior, instead of paying off the hall monitor so we all get to wear diapers because our pockets are small.

It’s not the maintenance so much as it’s the use. Again, ERAU is using these airplanes in a way that is probably not what anyone at Piper imagined.I'm not so sure blame can be assigned as an ERAU issue, yet, and I'm leaning toward no, unless they had a maintenance screwup.

We don’t know yet, but I would imagine that someone from the NTSB or FAA is looking into that. I sure hope that they would before publishing some widespread AD.Are other training Arrows owned by other schools showing similar problems?

It’s not the maintenance so much as it’s the use. Again, ERAU is using these airplanes in a way that is probably not what anyone at Piper imagined.

In 10,000 hours (pretty typical of Arrows) an ERAU Arrow will likely see two to three times more landings than your average flight school airplane. That’s a lot of long term abuse on an airplane and that’s the kind of thing that causes metal fatigue which is what the NTSB has found in two ERAU Arrows (the accident airplane one one other).

Now, just basic statistical probability: if an ERAU airplane is seeing 2-3 times more landings, they are also more likely to experience more ‘hard landings’ than the average flight school.

Now, the real truth as to whether this problem is an ERAU issue or airframe design issue won’t really be known until they start doing inspections on other high time (non-ERAU) airplanes.

I agree. Maybe it is ERAU, maybe it's the metallurgy of certain year's production models, or something else. Hopefully they conduct due diligence before issuing anything. They sure seem to be trying to investigate at a much faster pace than usual which I think is a good thing as long as it is thorough and doesn't prematurely jump to conclusions. If I owned an arrow I'd be comfortable flying in the mean time but following very closely.We don’t know yet, but I would imagine that someone from the NTSB or FAA is looking into that. I sure hope that they would before publishing some widespread AD.

I would bet there are very few student pilots that haven't landed hard at least once. I know that some of my early touch and goes were more accurately referred to as a "crash and dash".I am trying to understand why a hard landing might cause metal fatigue. I mean, before I'd expect a spar to experience irreversible damage, I would think that a pilot's back or neck muscles would incur serious injury. I realize that repetitive hard landings by different pilots might be one reason, but really, how many student pilots are really making such hard landings to warrant this concern?

There may be several mechanisms at play here. It may start as stress corrosion cracking and then transition to fatigue cracking once the cross section is reduced. It could be there is a problem with the metallurgy. It could be a problem with manufacturing and assembly.I am trying to understand why a hard landing might cause metal fatigue. I mean, before I'd expect a spar to experience irreversible damage, I would think that a pilot's back or neck muscles would incur serious injury. I realize that repetitive hard landings by different pilots might be one reason, but really, how many student pilots are really making such hard landings to warrant this concern?

I am trying to understand why a hard landing might cause metal fatigue. I mean, before I'd expect a spar to experience irreversible damage, I would think that a pilot's back or neck muscles would incur serious injury. I realize that repetitive hard landings by different pilots might be one reason, but really, how many student pilots are really making such hard landings to warrant this concern?

Metal fatigue occurs when abuse happens over and over and over and over againI am trying to understand why a hard landing might cause metal fatigue.

technically....there shouldn't be fatigue if there were proper design and manufacturing margins. That joint should have infinite life.Metal fatigue occurs when abuse happens over and over and over and over again

technically....there shouldn't be fatigue if there were proper design and manufacturing margins. That joint should have infinite life.

Why would you expect the landing gear itself to fail before the wing structures the gear is attached to???Repeat hard landings that cause the spar to separate should have crumbled the landing gear many times over.

Why would you expect the landing gear itself to fail before the wing structures the gear is attached to???

Go back in this thread and look at the photo I posted of the top of the wing. The gear on that airplane was absolutely fine. The wing, not so much....

It’s really the other way around in this case.The impact force from hard landing is transferred through the gear assembly to the wing. The gear needs to withstand the impact before any of that momentum change is transferred to the wing. That's why they make the front end of cars to crumble easily, so that they protect the impact from traveling to the passenger in case of a front end collision. I would assume, and hope, that the wing spar is a lot stronger than the landing gear. If it is really the other way around, that makes no sense to me.

That’s not physically possible. In order to make the wing structure stronger than the gear itself, the airplane would be so heavy it would never leave the ground.The impact force from hard landing is transferred through the gear assembly to the wing. The gear needs to withstand the impact before any of that momentum change is transferred to the wing. That's why they make the front end of cars to crumble easily, so that they protect the impact from traveling to the passenger in case of a front end collision. I would assume, and hope, that the wing spar is a lot stronger than the landing gear. If it is really the other way around, that makes no sense to me.

FAA found similar cracking in a non-ERAU privately owned aircraft not regularly used for flight training, and with similar total time on the airframe.

I missed it in the report also, but AvWeb pointed it out in a Flash release the same day as this NTSB report came out.

True in some cases. But in my experience, of all the investigative methods out there, metallurgy is one of the more precise when tracking down the causes of failure. In this case, with such a "clean" sample, the experts will provide pictures of the initial point/start of the failure, any additional issues, and include the approximate number of cycles it flew before failure. And I believe since this accident has priority we will know some details sooner than later.The really wonderful thing about metallurgy is that even the experts will argue about the causes.

I cannot address your experience. I can caution folks to understand that when an expert stands up and says "this is..." that expert is only offering an opinion and that opinion frequently ignores many aspects of the particular thing upon which the expert is pontificating. Many lawyers and expert witnesses have made tidy sums of money because of these expert opinions. Metallurgy is particularly susceptible because one expert identifies a crack initiation point at some defect and says "ah ha", the next expert reviews the test coupon properties and says "ah ha", and then a design guy reviews the loads and says "ah ha". After that it gets complicated.True in some cases. But in my experience, of all the investigative methods out there, metallurgy is one of the more precise when tracking down the causes of failure. In this case, with such a "clean" sample, the experts will provide pictures of the initial point/start of the failure, any additional issues, and include the approximate number of cycles it flew before failure. And I believe since this accident has priority we will know some details sooner than later.

It goes with the PhD and the expert witness fees. The judge doesn’t want to hear “holy sheet” in court. Guess he never heard of the shroud of Turin but that’s beside the point.Who are these people who say “ah ha”? I usually say, “holy ****!”

It goes with the PhD and the expert witness fees. The judge doesn’t want to hear “holy sheet” in court. Guess he never heard of the shroud of Turin but that’s beside the point.

This has been my main gripe (outside of one door) on the PA28... the gear.. that stubby little oleo strut goes straight into the wing. Many other fixed gears transfer the load more directly into the wingbox and airframe core as opposed to somewhere out on the wing causing a massive momentary bending moment at the wing root. Look at Grummans, Cirrus, TTx, heck even the Piper Tomohawk and current Piper Sport LSA have a gear system that absorbs much more of that bending moment itself and transfer it right in the wing box / fuselage (kind of like a Cessna highwing) rather than punching it straight up into the wingThe gear on that airplane was absolutely fine. The wing, not so much

That's physically impossible the way the gear is set up, that force will be transferred one way or another up into the wing. The oleo strut can be made softer, etc., to help dissipate that energy, but ultimately it is going to be transferred up into the wing given its current design. Piper should have used Tomohawk, Piper Sport, Grumman, Cirrus, etc., style gear. I imagine that would have been lighter and easier on maintenance tooThe gear needs to withstand the impact before any of that momentum change is transferred to the wing

I totally agree. The idea that "well this plane is used for training so the wings fall off at 7,000 hrs" is absurd. I have read that the PA28 airframe life is 62,900 hrs. **If an airplane is operated within its envelope then it should stay in one piece throughout its design life span** Sure, hard landings are an exception, but they DO happen.. and for a plane designed as a trainer as its primary role you would expect it to stay together, or be built with better failure modes that have a sheer pin between the wing and gear, or a different style gear altogetherPiper knows that the PAs they sell ERAU are used for training, and that they’ll be cycled through more hard landings than any other aircraft out there. Knowing that, there really should be extra steps taken for those aircraft.

It is not the paid expert witnesses I refer to, but the staff lab techs who produce the reports that your paid experts offer their varying opinions on before the court. And in most cases, any potential plaintiff experts are not even invited to the party until after the investigation is over and a claimant is filed. So they must rely on the same lab tech report.Many lawyers and expert witnesses have made tidy sums of money because of these expert opinions.

It appears that you have missed my point entirely which is that the precise identification of the crack initiation site may have nothing to do with the ultimate failure. A simple example which may be relevant here is that if the ultimate design load was exceeded it doesn't matter where the crack started because the structure was going to fail some way some how.It is not the paid expert witnesses I refer to, but the staff lab techs who produce the reports that your paid experts offer their varying opinions on before the court. And in most cases, any potential plaintiff experts are not even invited to the party until after the investigation is over and a claimant is filed. So they must rely on the same lab tech report.

The science part of metal research is very exacting down to the point of origin. These reports are detailed enough that even a lay-person with a basic understanding of the item can follow the path of failure. Pull any similar metallurgy report from the NTSB public docket and the detail is self-explanatory.

But to get back on topic it will be interesting to read the full lab report from this accident. And if the feds follow normal practice we'll will get a gist of that report if and when an AD is issued. However, you are correct that once the full report is out (which usually shows a single point of origin) that when we enter the tort litigation arena then one expert will state the point of origin was due to faulty maintenance, with the next expert stating fault was improper manufacture, etc. etc.

At least that is my experience.

good question....it might not be abuse as much as the flight profiles are intense & tough.....like take-off and landings only in certain aircraft with air work and x-country in another. That kind of intense use is not the norm across the PA-28 fleet nation wide. It would be a shame to implement some corrective action in an AD for all to perform.......

I mean, how hard is ERAU "abusing" these planes? I've heard some really passionate opinions about them.. but how does such a large flight school actually beat on their equipment that hard? You would think with a large organization the training culture and curriculum would be a well documented and professional outfit. Some people here make it seem like ERAU is a group of teenagers thinking they're Top Gun and over G'ing the planes on flights and slamming them down onto the runway. I mean, outside of some solo and XC time aren't most of the ERAU planes flown with an instructor?