NordicDave

En-Route

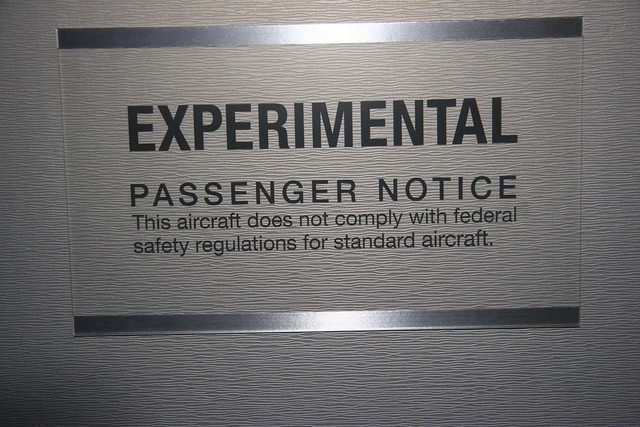

A gentleman in Brazil made an experimental Cessna 180 call it an Anssec 180.

Unfortunately it crashed: https://aviation-safety.net/wikibase/279998

Actually this spawns an interesting question regarding USA experimental aircraft.

Keeping the 51% rule in focus. Why couldn't a guy take a quality stripped Cessna airframe with complete empennage and no wings; and then build the wings, windows, interior, avionics, and control cables, etc for the remaining 51%?

Different permutations are possible like completed wings and fuselage, but tail section built from discrete parts.

A Van's quick build kit has the airframe aluminum complete except the empennage.

Unfortunately it crashed: https://aviation-safety.net/wikibase/279998

Actually this spawns an interesting question regarding USA experimental aircraft.

Keeping the 51% rule in focus. Why couldn't a guy take a quality stripped Cessna airframe with complete empennage and no wings; and then build the wings, windows, interior, avionics, and control cables, etc for the remaining 51%?

Different permutations are possible like completed wings and fuselage, but tail section built from discrete parts.

A Van's quick build kit has the airframe aluminum complete except the empennage.

Last edited: