You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

C150 Engine Upgrade

- Thread starter RussellJ

- Start date

francisco collazos

Pre-takeoff checklist

- Joined

- Jun 11, 2021

- Messages

- 354

- Display Name

Display name:

ciscovet

Touching on the skycatcher I recently found this video. I really enjoy this guys videos and he is very knowledgeable.

The channel is skywagon university and he does videos with local pattern flights on a lot of planes.

The channel is skywagon university and he does videos with local pattern flights on a lot of planes.

Grum.Man

En-Route

I don't think anyone suggest the O200 doesn't make more power than a C85 and from experience I know without a doubt it does. There are always rumors that a C90 makes more power than an O200 but I have never seen actual comparable evidence. I have seen dyno graphs and they all show the O200 making slightly more HP. The thrust test I've seen are comparing an O200 propped for a C150 vs a C90 propped for a 140A. The larger diameter prop on the 140A is going to make more static thrust. The proof I need to be a believer is the same diameter prop on both engines pitched to reach their static RPM rating. The C90 has a higher lift cam but is limited to 2475 rpm I believe. The O200 can run 2750 continuous.If the O-200 doesn't make more power/thrust than the C-85, why is it popular to replace the C-85s on 140s with O-200s?

1SGBrokePilot

Pre-Flight

- Joined

- Feb 27, 2017

- Messages

- 56

- Display Name

Display name:

EnlistedPilot

http://www.continentaldiesel.com/ has a diesel conversion. Interesting note, it has a 2,100hr replacement. It seems overhaul is not an option....or i misread everything

John Spartan

Pre-takeoff checklist

- Joined

- Mar 22, 2022

- Messages

- 316

- Display Name

Display name:

Spartan

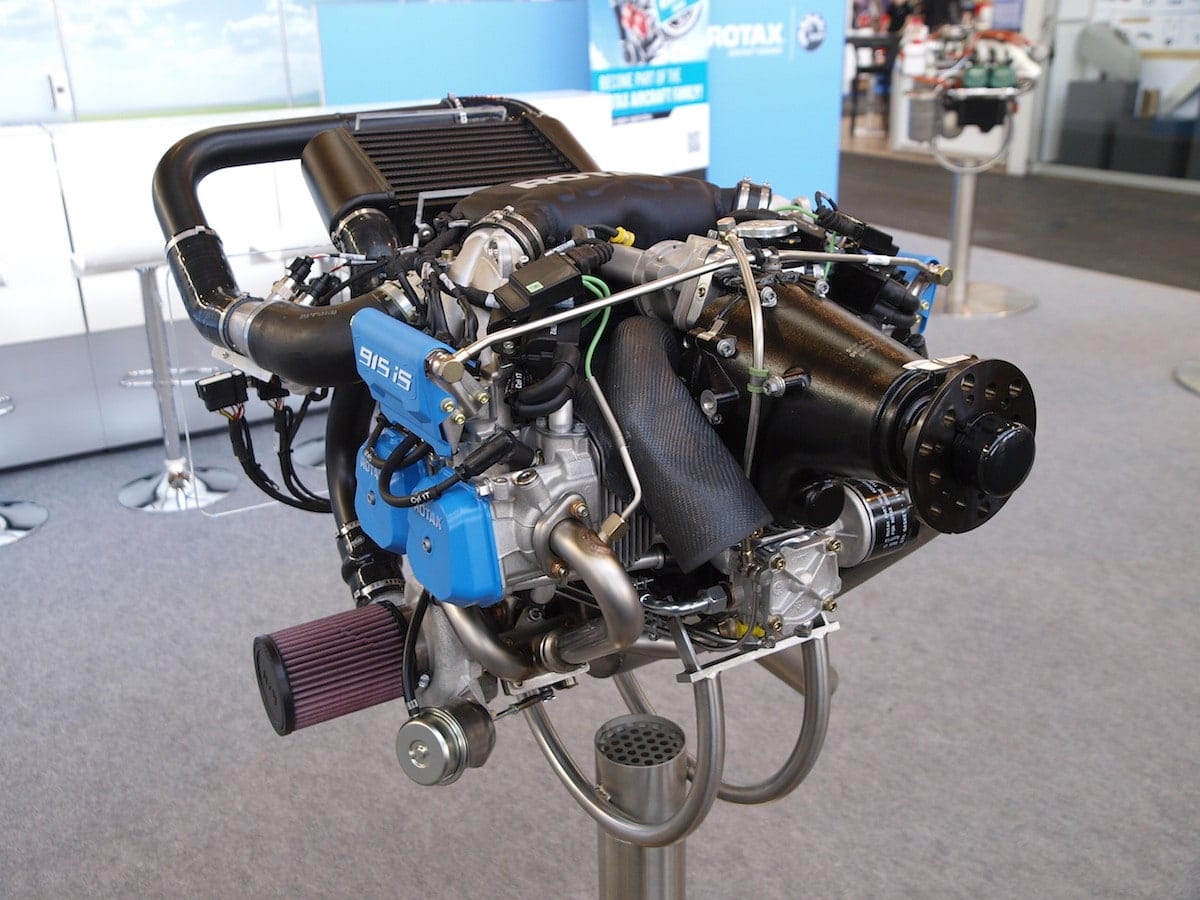

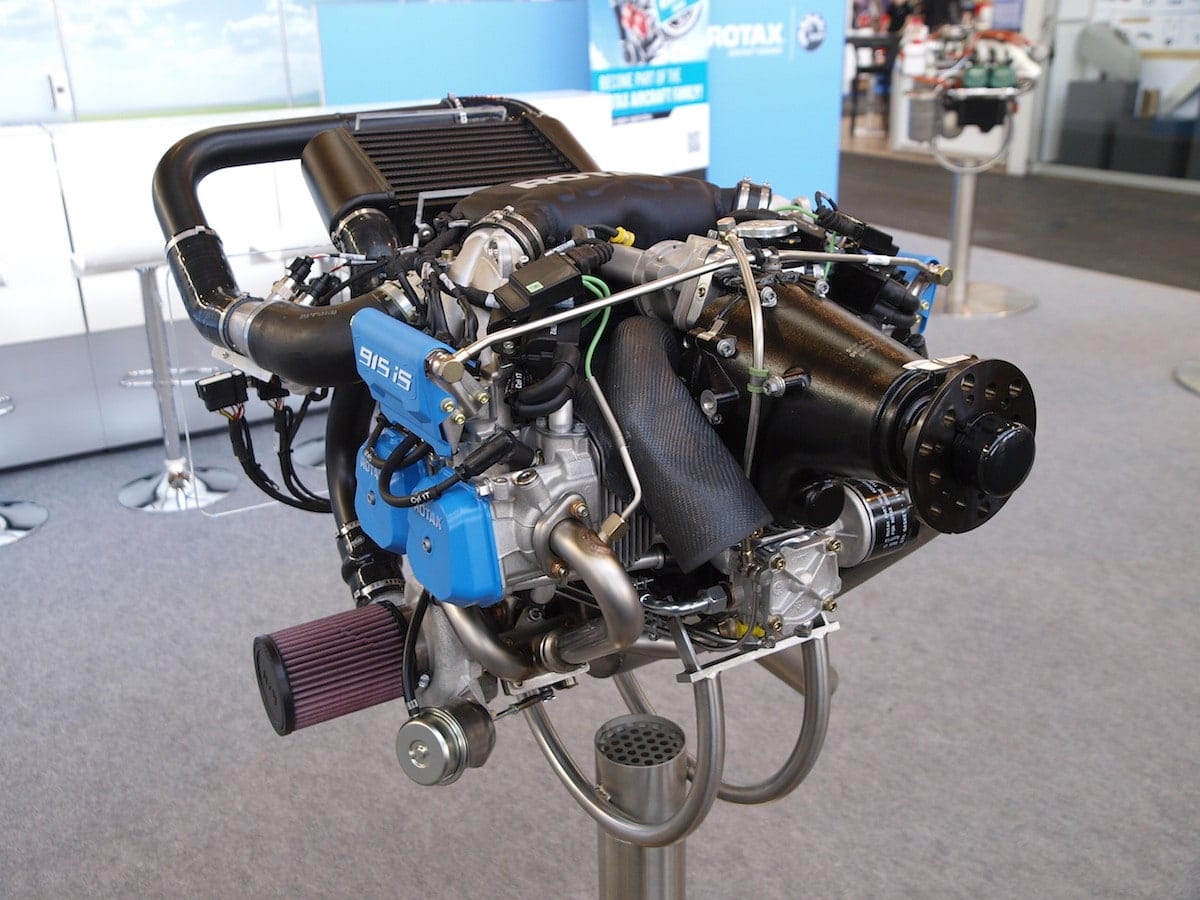

Rotax 915iS is 186.5 pounds

O-200 is 190 lbs

3.5 lbs of ballast and it seems like a doable option.

$35-38K Rotax new

3 gph at 100 knots so I'd bet faster at 5.3 GPH

generalaviationnews.com

generalaviationnews.com

$70k for an O-320 new assuming new

Best economy 5.3 GPH at 42% power

I know here is no STC but sure would be a neat way to keep these birds in the air

O-200 is 190 lbs

3.5 lbs of ballast and it seems like a doable option.

$35-38K Rotax new

3 gph at 100 knots so I'd bet faster at 5.3 GPH

Rotax’s powerful new 915iS — General Aviation News

$70k for an O-320 new assuming new

Best economy 5.3 GPH at 42% power

I know here is no STC but sure would be a neat way to keep these birds in the air

Ventucky Red

Pattern Altitude

- Joined

- Jan 9, 2013

- Messages

- 1,994

- Display Name

Display name:

Jon

Thinking with all the 150's out there, there isn't an STC for the Continental 0-240 that Reims did for the Areobat

Steamflyer

Pre-takeoff checklist

- Joined

- Mar 23, 2022

- Messages

- 402

- Display Name

Display name:

Steamflyer

So you actually bought a 152 with Lycoming cylinders and most likely 108 hp. The retarding AD on Continentals is unlikely to be applicable to many engine still in the fleet (though it is possible of course).The Cessna 150's O-200 had at one time an AD that required retarding the mag timing. I bought such a 150 and realized that because it had actual Lycoming cylinders, the mag timing could be returned to the original. it definitely made a difference, especially in climb performance. It would be worthwhile to investigate the paperwork for the plane in question. You may be able to gain some "free" horsepower.

A 120 or 140 with a stroked C85 is a very good performer, but so is a light 150 with the O200.

PilotAl

Filing Flight Plan

- Joined

- Oct 7, 2023

- Messages

- 2

- Display Name

Display name:

PilotAl

Brand new to the site…first post so “Howdy”! I had a 1972 A150L Aerobat growing up in the 1980’s and we looked into putting a 150hp conversion on it (which it desperately needed for Aerobatics)…problem was the conversion took the aerobatic certification away …Thinking with all the 150's out there, there isn't an STC for the Continental 0-240 that Reims did for the Areobat

Cessna putting the continental in the skycatcher instead of a rotax has always seemed like a miss, especially considering the prototype has a rotax

But then again, there's a lot of things about the 162 that was a miss.

But then again, there's a lot of things about the 162 that was a miss.

John Spartan

Pre-takeoff checklist

- Joined

- Mar 22, 2022

- Messages

- 316

- Display Name

Display name:

Spartan

Welcome aboard!Brand new to the site…first post so “Howdy”! I had a 1972 A150L Aerobat growing up in the 1980’s and we looked into putting a 150hp conversion on it (which it desperately needed for Aerobatics)…problem was the conversion took the aerobatic certification away …

Punkinhead

Pre-takeoff checklist

- Joined

- Sep 23, 2018

- Messages

- 107

- Display Name

Display name:

Punkinhead

Parts availability.If the O-200 doesn't make more power/thrust than the C-85, why is it popular to replace the C-85s on 140s with O-200s?

Like souping up a Volkswagen beetle. You can put a turbocharger on it, but it's still a bug.

Of course, I've flown one of these reengined 150s and it is a hoot (almost as much fun as a fast beetle).

Of course, I've flown one of these reengined 150s and it is a hoot (almost as much fun as a fast beetle).

John Spartan

Pre-takeoff checklist

- Joined

- Mar 22, 2022

- Messages

- 316

- Display Name

Display name:

Spartan

Is there a cost to the shop to get an STC approved by FAA?

Last edited:

Fast Lane

Filing Flight Plan

My 150 needs an overhaul soon. Not sure what to do since the price to overhaul is so insane. Glorified lawn mower engine. Leaded fuel will be done for sooner than later. I would rather put a Rotax in it.

WDD

Final Approach

- Joined

- Oct 16, 2019

- Messages

- 5,379

- Location

- Atlanta / KRYY

- Display Name

Display name:

Vintage Snazzy (so my adult children say)

If you’re willing to share - what is the overhaul cost that you’re looking at?

Fast Lane

Filing Flight Plan

Its impossible to get any remotely firm prices out of anyone locally. I assume cam and lifters are all junk at this point. New bearings. Cylinders are all fairly new. Bottom end hasn't been open since 1973 so..... 2200 SMOH. I still have great oil pressure and 10-13 hours before dumping in another quart. One OH shop said to run it until 2500 hours then overhaul.

farmrjohn

Pre-takeoff checklist

- Joined

- Mar 26, 2018

- Messages

- 409

- Display Name

Display name:

farmrjohn

I'd be happy if someone could come up with an STC to replace the O-200 with a Rotax as an engine change only and not a change to the aircraft (not enough of mine made to make it cost effective to get an STC for the aircraft). That's not going to happen, alas.

John Spartan

Pre-takeoff checklist

- Joined

- Mar 22, 2022

- Messages

- 316

- Display Name

Display name:

Spartan

makes sense to me. Rotax appears to be about 10k cheaper for the same or better turbo power.I'd be happy if someone could come up with an STC to replace the O-200 with a Rotax as an engine change only and not a change to the aircraft (not enough of mine made to make it cost effective to get an STC for the aircraft). That's not going to happen, alas.

FWIW: I believe someone did get an STC in the EU and is stilling working on getting it approved in the US. But you also could go the Experimental/Exhibition route and put a Rotax on your aircraft with as minimal modifications as you want right now. Its one route a number of people have taken to install different engines without an STC. Why wait on someone else to do the work?I'd be happy if someone could come up with an STC to replace the O-200 with a Rotax as an engine change only and not a change to the aircraft

And essentially nobody with an aircraft in the value range of those fitted with an O-200 is going to select either of those options. They will instead have their existing engine overhauled or IRAN'd by an independent engine shop or A&P mechanic, at lower cost. Cessna 150s and the like are mostly hobby planes in 2023, with owners unwilling to splurge on unnecessary expenses. These are planes that independent owners fly for limited hours and keep running at minimum cost. Flight schools with money fly 172s and Pipers.For an O-200 it's 46K for a factory new and 44K for a factory overhauled engine.

The Rotax 915 idea is a pipe dream. Putting a very expensive liquid cooled, geared, turbocharged, EFI engine with a constant speed prop on a very simple, basic, low value used aircraft with an expensive STC conversion kit is not something the market will choose, or has chosen. The French company that tried to market the idea using a simpler 912 Rotax (that like the 915 also requires a wood CS prop to work) failed to sell an appreciable number of conversions over the years they tried to do so. If I understand the website correctly they sold the EASA STC rights in 2017 to somebody in Finland.

ROTAX CESSNA

A prototype was built and flown years ago, I believe a few sales followed but a year and half ago the website again said “A goal has been set to convert one C150 in 2022 to gain experience in the production to cover possible pitfalls and to get precise understanding of the actual cost of STC kit. After first conversion a full scale production capability should be achieved”

Last edited:

Ventucky Red

Pattern Altitude

- Joined

- Jan 9, 2013

- Messages

- 1,994

- Display Name

Display name:

Jon

Cessna putting the continental in the skycatcher instead of a rotax has always seemed like a miss, especially considering the prototype has a rotax

But then again, there's a lot of things about the 162 that was a miss.

Didn't they destroy the last remaining airframes?

bnt83

Final Approach

I would make a spreadsheet and summarize the total time on components and the dates they were installed for magnetos, spark plugs, spark plug wires, exhausts, alternator, vacuum pump, cylinders, hoses, oil cooler, engine mount, and go from there. If some of those are pretty new then it makes zero sense to replace them.Its impossible to get any remotely firm prices out of anyone locally. I assume cam and lifters are all junk at this point. New bearings. Cylinders are all fairly new. Bottom end hasn't been open since 1973 so..... 2200 SMOH. I still have great oil pressure and 10-13 hours before dumping in another quart. One OH shop said to run it until 2500 hours then overhaul.

Core engine overhaul, $1700 crankshaft, maybe $700 rods, $400 on rockers, $1200 crankcase, maybe $1k in bearings and bolts, new cam & lifters or reground ones is gonna be a personal choice.

The last O200 I overhauled was kind of a worn out pile. It needed a new accessory case as the oil pump cavity was worn out, the cam gear NDTed cracked, the magneto drive gears and bushings were shot and the crankshaft was unusable.

There is zero reason not to buy a set of new cylinders long before you overhaul. Just make sure they are preserved correctly or they may be rusted out trash when you finally use them. Inspect them as soon as they are delivered as I have gotten brand new cylinders with corroded barrels and rejected them the day they showed up. AND DO NOT LOSE THE PAPERWORK FOR THEM. You may end up just selling them at some point like if your airplane got totaled by tornado or something.

Last edited: