So I'm actually wondering if now is the time to hop off of the fence and try my hand at an RV-14 build. I've been hemming and hawing about it for a long time.

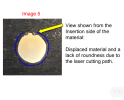

My thinking is -- I'm "new money" so I get to cut line in front of the rubes who are renegotiating their BK'ed contracts. Parts QA scrutiny is likely at a high point right now. I can plant the flag on my build as a "post-snafu" build which will avoid the cloud of the older planes. It's going to be like the ruddervator fiasco for RV sellers for the next decade or two. "Did you have them thar laser holes in your plane?" -- I can skip that entire category of BS.

Of course, building a plane seems to be its own category of BS, so I'm still hesitant to commit to 2 or 3000 hours of frustration and my own ineptitude. But maybe it'd be fun?

We have a new EAA chapter at my airport, so seems there is a lot of support or commiserating available.