My mechanic is oftentimes slow to get to me so I'm grounded until he looks at my prop. Anyone want to armchair quarterback this one?

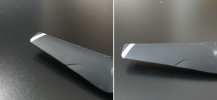

During my flight training I was taught all about leading edge dings. But I fail to recall being taught about surface dings. I found this one while changing my oil last week. Must've happened on my last flight.

It seems shallow to me. Run your finger nail over it and you feel ridges.

There are size limitations and depth limitations right? How do you measure depth on the surface? It's so shallow nothing would measure it. It's a Hartzell if that matters. Haven't flown it since but would've loved to shoot some approaches this morning in actual. We need new mechanic blood here if anyone wants to move here. @Bell206

During my flight training I was taught all about leading edge dings. But I fail to recall being taught about surface dings. I found this one while changing my oil last week. Must've happened on my last flight.

It seems shallow to me. Run your finger nail over it and you feel ridges.

There are size limitations and depth limitations right? How do you measure depth on the surface? It's so shallow nothing would measure it. It's a Hartzell if that matters. Haven't flown it since but would've loved to shoot some approaches this morning in actual. We need new mechanic blood here if anyone wants to move here. @Bell206