Checkout_my_Six

Touchdown! Greaser!

Gonna have to add em up....

Or use a progressive inspection?I wonder how many aircraft in training fleets get annual inspections instead of 100 hour inspections?

This might be a stupid idea, but especially considering the PA28 is still in production is there any chance of a redesign/modification to strengthen the problem area?

It is also a 60 plus year old design. It has (if I remember correctly) 2 reported failures outside of failures that were determined to have occurred because the airframe was overloaded due to pilot error. I found that about 33000 various PA28's and about 7800 PA32's have been built. So around 41000 planes have this wing spar setup, and who knows how many flight hours. That is a 0.005% failure rate that can be attributed possibly to the structure and was outside of pilot control.This might be a stupid idea, but especially considering the PA28 is still in production is there any chance of a redesign/modification to strengthen the problem area?

Out of curiosity, I own a PA32R- 301. I noticed the AD applies to PA32's with the 300 designation but not the 301's. What changed?

Sent from my SM-G950U using Tapatalk

I'll believe when the final version of this AD is written, you'll have 229 hours until your aircraft hits the magic mark.I really don't yet understand how this works for a plane that has been used for flight training, but the logs mostly show an annual inspection, not a 100 hr inspection.

I'll use my PA28-181 as an example.

There are a total of 53 annual or 100 hr inspections in the logs. The plane was mostly used as a trainer, but the logs show only 14 100 hr inspections and 39 annual inspections. I looked through the title history and overlayed that with the annual completion and have at least 13 real annuals to private owners, which could leave a potential of 40 100 hrs. total time is 4771.

According to the formula, how many calculated hours do I have?

(14 x 100) + (4771 - (1400)/17= 1598 hrs

or

(40 x 100) + (4771- 4000)/17= 4045 hrs

Either way I am under the limit, but the calculated time is dramatically different. Even at the higher number, I have 16,235 more personal flight hours before I hit the 5000 mark.

I really don't yet understand how this works for a plane that has been used for flight training, but the logs mostly show an annual inspection, not a 100 hr inspection.

I'll use my PA28-181 as an example.

There are a total of 53 annual or 100 hr inspections in the logs. The plane was mostly used as a trainer, but the logs show only 14 100 hr inspections and 39 annual inspections. I looked through the title history and overlayed that with the annual completion and have at least 13 real annuals to private owners, which could leave a potential of 40 100 hrs. total time is 4771.

According to the formula, how many calculated hours do I have?

(14 x 100) + (4771 - (1400)/17= 1598 hrs

or

(40 x 100) + (4771- 4000)/17= 4045 hrs

Either way I am under the limit, but the calculated time is dramatically different. Even at the higher number, I have 16,235 more personal flight hours before I hit the 5000 mark.

Better keep quiet. I think the 28-181's got left out at first but they are in there now.

I really don't yet understand how this works for a plane that has been used for flight training, but the logs mostly show an annual inspection, not a 100 hr inspection.

Not quite. It's not "53 annual or 100 hr..." Only 100 hr inspections. Most aircraft have an inspection done every 12 months (1 inspection annually). If an aircraft is used for compensation (training) then an inspection is due every 100 hours of operating time which could be once a week for the same 12 month period (52 inspections annually). The feds are trying to separate aircraft into groups based on individual 100 hr inspections and not annual inspections. But still too many variables to their AD plan to make a call as an "annual" sign-off is not technically a "100hr" sign-off.There are a total of 53 annual or 100 hr inspections in the logs.

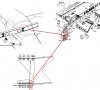

Not necessarily. They make a number of specialized EC probes to inspect bolt holes as installed. They can pull one bolt at a time, check the hole, then reinstall the bolt. And so on. The AD only requires the lower spar cap bolt holes to be inspected. The main problem will be getting the bolts out.it basically requires pulling the wings,

not when they are looseNot necessarily. They make a number of specialized EC probes to inspect bolt holes as installed. They can pull one bolt at a time, check the hole, then reinstall the bolt. And so on. The AD only requires the lower spar cap bolt holes to be inspected. The main problem will be getting the bolts out.

I actually disagree that tt is just as effective. The FAA is clearly trying to separate commercial flight school use from personal use aircraft. Flight school aircraft are used much harder and each hr of tt is not equivalent. A personal plane will mostly be doing point to point flights or local sight seeing. This involves 1 take of and landings per flight. For arguments sake this is 1 cycle per hour of flight time.my comment was submitted.

Comment:Appendix 1 to the AD requires methods in excess to find cracks in this installation. requiring Eddy Current inspections by certified personal removes this AD from the capability of most A&P -IAs that do the annual or 100 hour inspections on aircraft not in training school environment.

Having certified persons with the equipment to complete this inspection will add expenses that are not considered in the cost computed by the FAA.

Secondly the complicated method of computing which aircraft this inspection will include will cause great confusion, when the standard of Total time on the Airframe will be just as effective. By placing the time requirement on the wing beam in all practically places a time life on the wing.

I actually disagree that tt is just as effective. The FAA is clearly trying to separate commercial flight school use from personal use aircraft. Flight school aircraft are used much harder and each hr of tt is not equivalent. A personal plane will mostly be doing point to point flights or local sight seeing. This involves 1 take of and landings per flight. For arguments sake this is 1 cycle per hour of flight time.

With my own plane I have done maybe 3 in an hour, but rarely do I just stay in the pattern and repeat cycles rapidly.

In a training situation it is not uncommon for pattern work where you can get as high as 6 maybe even 8 take off and landings per hour. That is 6 cycles, and the stress on the airframe for that 1 hour of flight time is not equal.

The 100 hr part of the equation is the most realistic statistic in the log to determine if a plane has ever been used for commercial purposes (I know is can be manipulated, and they will need to look into that). I personally think the divided by 17 part of the equation may be a bit generous ( do not kill me for that), and perhaps that number should be more in the 10 to 15 range. But I applaud the FAA for attempting to not financially kill private owners and risk partially grounding what has historically been a great airframe.

Sent from my SM-G950U using Tapatalk

I also would add to be previous statement, that if you count just tt as was suggested about and apply that "logic" to the FAA equation, it would mean that at about 5000 tt all PA28's would be required to have this possible invasive spar inspection. That would in effect be putting a 5000 hr lifespan on the plane, if the costs to inspect are in fact onerous.Agreed. And not "has been", it is a great airframe. That Embry Riddle decided to socialize losses like the greedy piggies they are, does not take away merit from the airframe and thankfully in this case the FAA has found some modicum on nuance (even a blind squirrel finds a nut every now and again).

I've owned two PA-28s in my tenure in this hobby and have been delighted with the dispatch reliability and ease of airframe and engine mx of the type. The embedded opportunity costs is that it is popular with flight schools and as such we eat the losses when one craps their pants... and we all get told to wear diapers.

See ? already much confusion, and personal opinion inserted in how to read what the FAA intendsThe 100 hr part of the equation is the most realistic statistic in the log to determine if a plane has ever been used for commercial purposes (I know is can be manipulated, and they will need to look into that)

No one is arguing how great an aircraft the PA-series are.Agreed. And not "has been", it is a great airframe. That Embry Riddle decided to socialize losses like the greedy piggies they are, does not take away merit from the airframe and thankfully in this case the FAA has found some modicum on nuance (even a blind squirrel finds a nut every now and again).

I've owned two PA-28s in my tenure in this hobby and have been delighted with the dispatch reliability and ease of airframe and engine mx of the type. The embedded opportunity costs is that it is popular with flight schools and as such we eat the losses when one craps their pants... and we all get told to wear diapers.

We all know that the high time aircraft are the ones the FAA is worried about because they are the ones most likely to be the the ones in training environment. Lots of CFIs teach in their own aircraft then rent it to their students, Renting is not considered a commercial activity. but will put as much stress and time as a flight school.I actually disagree that tt is just as effective. The FAA is clearly trying to separate commercial flight school use from personal use aircraft.

The one item that is not very prominent in this discussion is that this will be the 2nd time an AD is issued, the 2nd time wing spar times will be factored, and the 2nd time the Feds/Piper are trying to segregate aircraft by operation type on the PA-28 family. The 1st was in 1987 when a pipe-patrol aircraft had a lower spar cap failure in flight. At that time the trigger wasn't 100hr inspections but aircraft that operated at 1000' AGL continuously.but only 2 failures, and I think they found 1 other plane with cracks.

I had forgotten about the previous AD that was suspended. I knew about the 87 crashThe one item that is not very prominent in this discussion is that this will be the 2nd time an AD, the 2nd time wing spar times will be factored, and the 2nd time the Feds/Piper are trying to segregate PA-28 aircraft based on operation type. The 1st was in 1987 when a pipe-patrol aircraft had a lower spar cap failure in flight. At that time the trigger wasn't 100hr inspections but aircraft that operated at 1000' AGL continuously.

AD87-08-08 required the wings removed for a spar inspection at the magic 5,000 hr mark. However, after 500+ inspections no more cracks so the FAA suspended the AD and the inspection went back to the SB level. The docket lists 2 previous Piper SBs (which are linked in post #35) that explains this more.

I'd recommend those PA aircraft owners possibly affected to enter a docket comment in favor of a more reasonable inspection that can be accomplished at field level by an A&P like fluorescent dye check or a 10x visual of the bolt hole area with the bolt removed. And while I like the factored approach to this inspection too many variables exist to make the current formula workable. Maybe a straight X+Y=Z factor based on ownership type may work better or number of total inspections per year as a factor with 1 per year being the control or base to calculate from.

Just remember how important those fuel selector decals were recently.

All of them, the annual retirement does not go away just because it had a 100 hour.I wonder how many aircraft in training fleets get annual inspections instead of 100 hour inspections?

Progressive inspections still must be completed each year.Or use a progressive inspection?

True. But the context of that comment and the one responded to was if an operator signed off all their inspections as "annuals" or used a progressive inspection there would be no "100hr inspection" history in the aircraft logs as specifically defined in the proposed AD.Progressive inspections still must be completed each year.

This is why A/F TT is the only way to sort out the loose wings. One time inspection on all PA-28 with over 5000 hours.True. But the context of that comment and the one responded to was if an operator signed off all their inspections as "annuals" or used a progressive inspection there would be no "100hr inspection" history in the aircraft logs as specifically defined in the proposed AD.

disagree....Tom.

landing cycles causes fatigue....not total time.

no....that's not correct.Landing cycles get counted in TT no matter what the usage.

For this purpose it certainly is.no....that's not correct.

Landing cycles get counted in TT no matter what the usage.

For small planes they aren't, that is the issue here. The high landing cycles are the likely cause of the failure. With this equation the FAA is trying to estimate landing cycles.I’ll bite, how do landing cycles get counted?