"Hypothetically" speaking...

Airport manager does not call the FAA or NTSB.

Insurance would rather not pay for transporting the aircraft by land but will do so if there are extenuating circumstances.

FAA is not keen on issuing ferry permits. Probably depends on local FSDO.

Switching out the prop or flying it with a bent prop tip is risky if you get a ramp check at the destination (unless it happened at the "destination" airport).

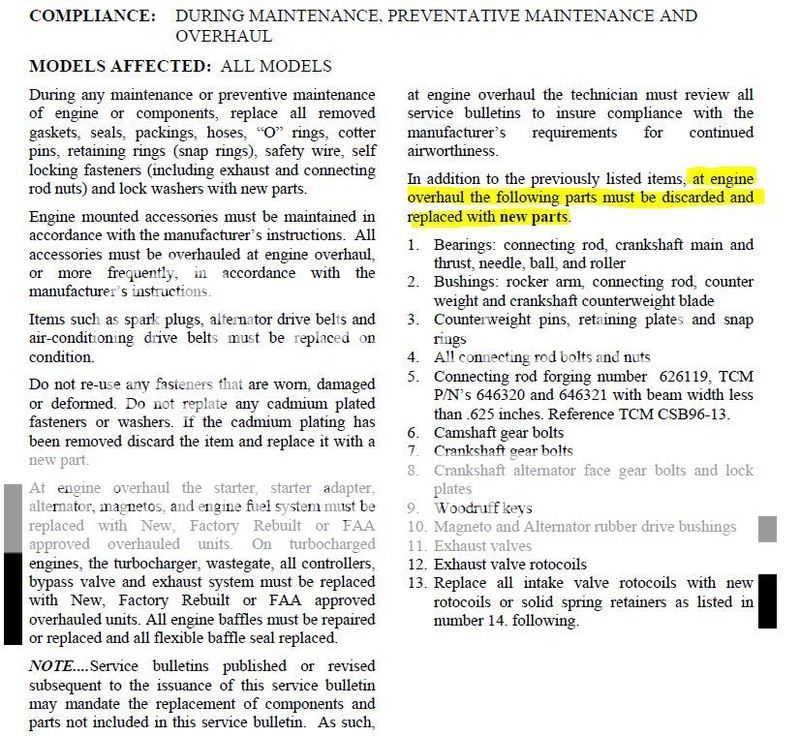

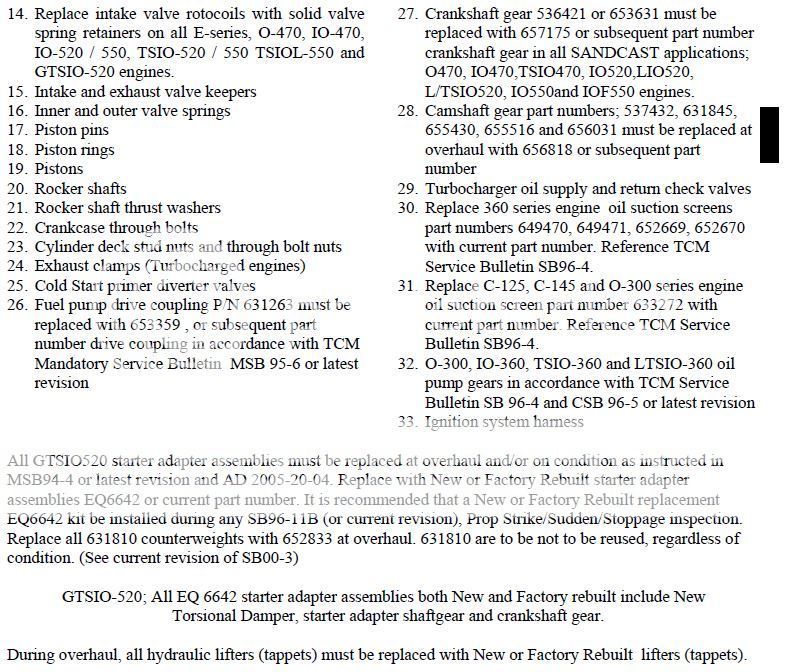

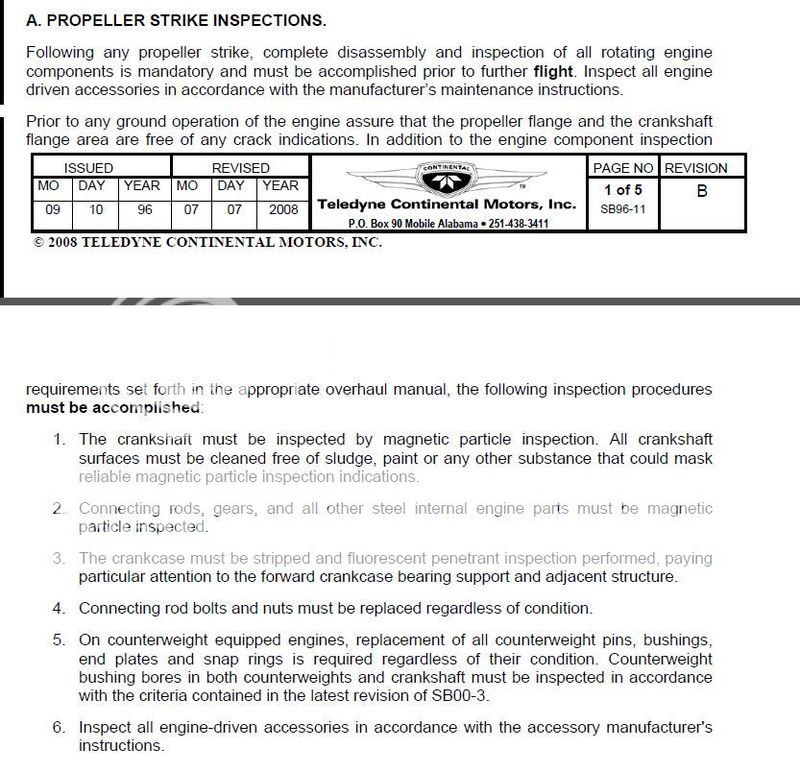

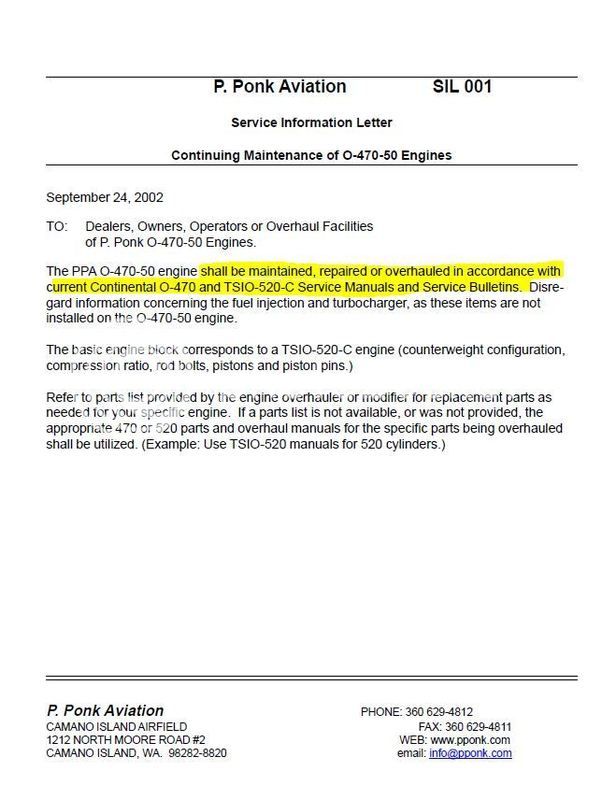

Cost of a teardown inspection for a Continental O-470S1B is approx $10,500. If damage is found, parts are additional.

Cost of an overhaul on O-470S1B is approx $26,500. Depends on cylinder choices.

Cost of a factory rebuilt O-470S1B is $27,647. plus shipping with a core exchange.

TBO for factory rebuilt is extended to 1,700 hours vs. 1,500 for overhaul.

Insurance does not pay for any parts/components not directly attributable to the prop strike, i.e., Lord mounts, engine baffling, hoses etc., unless they were damaged as a result of a prop strike.

Insurance pays for the cost of the teardown inspection/repair. They are happy if the owner decides to overhaul or replaces with new or factory rebuilt since they no longer worry about hidden damage.

"Right" thing to do is take conservative approach, ground the aircraft, and either have the plane moved by ground transport or pull the engine for repair/replacement at the site.