Friday night we saw Ford v. Ferrari in an IMAX theater. I think the last time I saw a car on opening weekend would've been 15 or more years ago. No movie since has made me want to see it on opening weekend, and few have even been interesting enough to me to bother wanting to see them in theaters. I've been eagerly anticipating this movie since June 3rd, when the initial trailer was released.

Since the Cobra wasn't ready, we instead drove the XKR. Not a Ford or a Ferrari, but was built when Ford owned Jaguar, and still a performance car. Sadly, the local Cobra club didn't arrange a group drive-in like they'd originally said they would when the movie was announced. But Laurie and I used it as a date night, and the Cobra wasn't ready anyway, so just as well.

Without giving anything away, the movie did not disappoint at all. Obviously it's Hollywood so there were some inaccuracies, but I was frankly amazed at just how accurate it was on the whole. The driving scenes were fantastic with little for me to complain about as far as inaccuracies go. I am no expert on the history of the GT40, but from what I know, they did seem to try to keep things largely accurate. The story is incredible enough that it didn't need to be embellished or exaggerated much, although of course most (if not all) of the script was fabricated. The movie was very worth seeing, and one that makes me both excited and proud to be building a Cobra replica.

I'm at least somewhat disappointed that I didn't have the Cobra ready in time for the opening night. A movie of this magnitude does not come around often. However with Laurie and I have a date night and with the chilly temps, it wouldn't have been a particularly pleasant drive. To get the Cobra completed in time would've been doable, but ultimately stressful to have a deadline. As a friend of mine pointed out, for projects such as these, it is better not to have deadlines.

The movie does leave me more conflicted on whether to build a GT40 replica or an XJ13 replica as the next car. Something I like about the GT40 is that it's possible to build a replica that's correct (at least largely so) down to the engines used. The story of the GT40 is a fantastic one, and while the engines were racing engines (whether 289 or 427) they were also still Ford engines. The XJ13 ultimately is the racecar that never was, and the engine used in it was a Jaguar V12, but significantly different from what became the V12 used in the E-types, XJ-Ss, and XJ12s (along with others). For me engines are a big deal, and if building a replica of a car I like for there to be a level of authenticity to some extent.

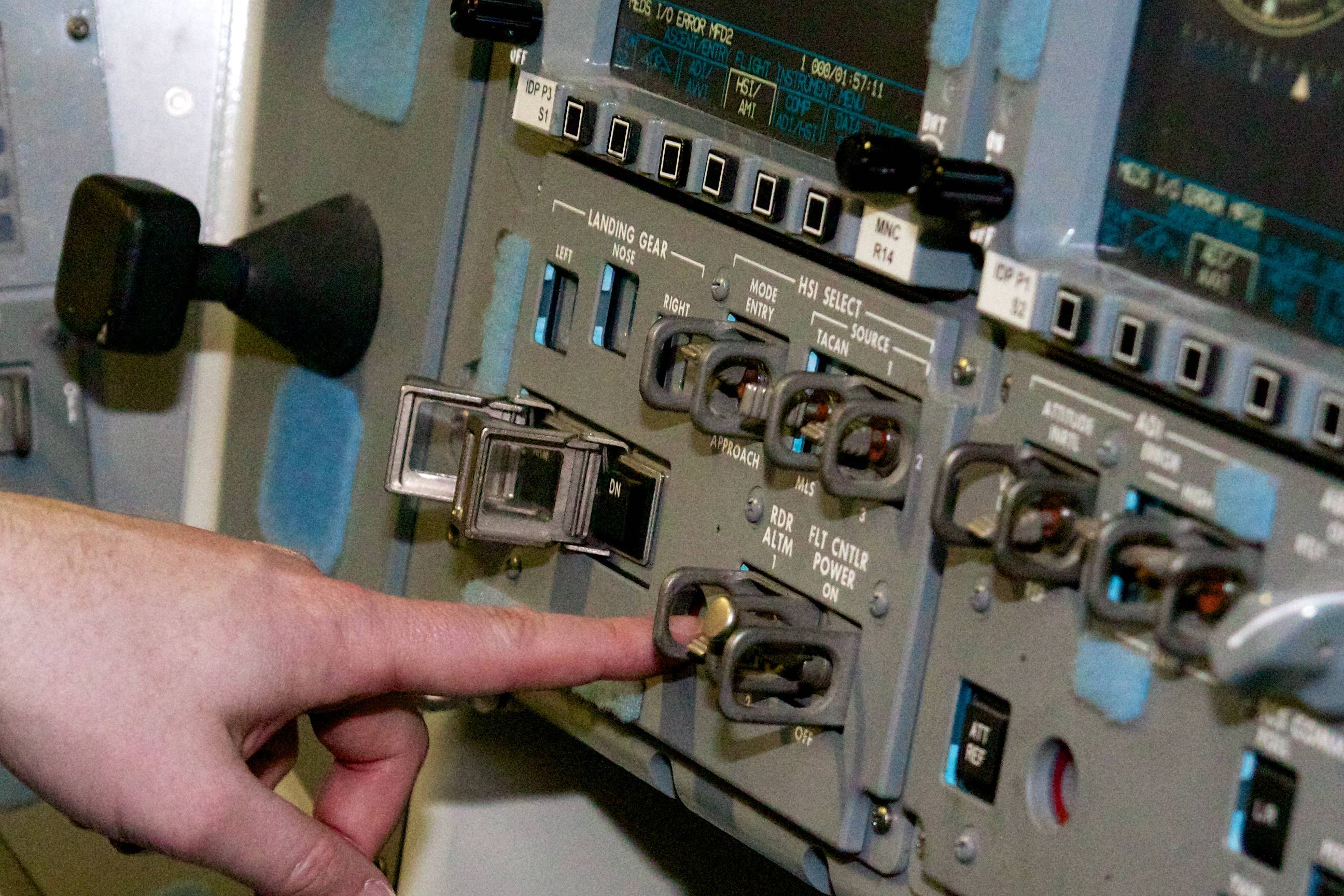

Either way, the next car is a long ways off, I still have this car to work on. And while first start is something that I can see happening, it's not there... yet.

).

).