For the engine analyzer, there's not much needed in the panel other than connecting the wiring to the display in the panel. If it's a JPI or EI, the wiring diagram comes along with the gear and display. On the JPI they are DB9 and DB15. If Radio Shack were still around, you could go there and get the plugs.

If an A&P is unwilling to install an analyzer, I'd really wonder about the A&Ps qualifications. As for removing old stuff, again, it's removing the displays, removing the wiring from the antennas (which should be removed, too), and removing the wiring to the electrical system. Wouldn't hurt to have the airplane weighed after all this is done. When I had 40 yr old wiring and gear removed, I gained 10 pounds of load!

I hung out at the shop while they were installing the JPI - punch holes and install the probes. GPS isn't required for analyzer, but is an add-on. If you don't have a GPS, no need for that wiring.

Here's the back of the JPI 730 - standard connectors.

View attachment 92972

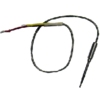

Here's the EGT probe and the CHT probe :

View attachment 92973 View attachment 92974

If the A&P doesn't understand how to take the end of the CHT or EGT cable, get the correct connector (DB9 or DB15 on the JPI) and crimp the wire into the connector, they should go back and take General again. This is all stuff taught in A&P school, nothing out of the ordinary. But that's my opinion.