You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Best Phillips bits

- Thread starter manac

- Start date

Craig

Cleared for Takeoff

We buy nothing but Wera tips at work these days. Don't know about their Phillips ones, as all ours are Torx. One thing that will help no matter who's tips you get, is grind off the point, so the end of the tip is a a bit flatter.

- Joined

- Apr 5, 2017

- Messages

- 3,886

- Location

- hopefully not at work

- Display Name

Display name:

Meet the Fokkers

For impact, but.....

manac

Pre-takeoff checklist

- Joined

- Oct 16, 2007

- Messages

- 260

- Display Name

Display name:

Manac

I’d never use an impact or power driver for a annual. Snap On ratcheting screwdriver only. I think you have to feel every fastener as you remove it and reinstall. I also think there’s a difference between a hand bit vs power. Stripping something on any plane isn’t an option.

Craig

Cleared for Takeoff

One thing we encountered a lot of years ago, was that install/removal rpm of a fastener had a lot to do with having them gall and seize. One can run screws in and out fast enough with a speed handle to give you 2nd and 3rd degree burns when you touch the hardware. That burns off any corrosion preventative or lubrication on the screw or in the nut/nutplate. I've pulled titanium screws out so fast with a speed handle, that they are smoking when they hit the floor. Power tools only exacerbate the problem.

Most of the bits I use are Zephyr brand from Omega Tech which I believe are the supplier for Snap-On or at least were and at a much better price. APEX is my 2nd choice. And a 1/4" speed-handle does wonders for the wrist when needed on big jobs.Any recommendations?

Last edited:

- Joined

- Apr 5, 2017

- Messages

- 3,886

- Location

- hopefully not at work

- Display Name

Display name:

Meet the Fokkers

It's just a review on bits, not a suggestion to use an impact driver for annual.

Stripping something on any plane isn’t an option.

Apparently many people who worked on my plane over the last 53 years disagree with you. Opening it up for its annual a few months ago, it seemed like every third screw had a stripped head.

Craig

Cleared for Takeoff

Got to use a screw knocker and rivet gun at times, as a last resort before drilling....If I've got access to one, then a Brutus Bar before the knocker..

Not sure what a snap on acr is?

IMO snap on makes one of the best screw drivers, long shaft too. Long shank screw drivers are easier to use when you have the room even if you don't need a long shank.

about a year ago I bought a battery screwdriver, I think it is a dewalt? Yellow...it is handy for disassembly and is light enough that you do develop a feel using it. Never thought I'd like but I do. Can't find a picture of it.

I use that red Philips for every thing, use it to final tighten screws. It wears out and I get a fresh ones every 5 years or so. I have wore out a few in 30 years. I'll use a mix of tools but only snap on for screwdrivers.

FWIW I put the screws back into the hole it came out of during annuals. No bagging and tagging. Sometimes I use painters tape and tape hardware to a cover plate or something if I can't put the screw back in the hole it came out of. Don't think there is 2000 screws on my 172?

IMO snap on makes one of the best screw drivers, long shaft too. Long shank screw drivers are easier to use when you have the room even if you don't need a long shank.

about a year ago I bought a battery screwdriver, I think it is a dewalt? Yellow...it is handy for disassembly and is light enough that you do develop a feel using it. Never thought I'd like but I do. Can't find a picture of it.

I use that red Philips for every thing, use it to final tighten screws. It wears out and I get a fresh ones every 5 years or so. I have wore out a few in 30 years. I'll use a mix of tools but only snap on for screwdrivers.

FWIW I put the screws back into the hole it came out of during annuals. No bagging and tagging. Sometimes I use painters tape and tape hardware to a cover plate or something if I can't put the screw back in the hole it came out of. Don't think there is 2000 screws on my 172?

Last edited:

ACR is a type of Phillips head driver bit. Basically a Phillips with ribs on the "flanges" for better grip. A number of producers make ACR style bits of varying quality.Not sure what a snap on acr is?

Thanks, pretty sure the snap on tips have used that for many years. Now we can't get snap on scewdrivers?? What is this world coming to?ACR is a type of Phillips head driver bit. Basically a Phillips with ribs on the "flanges" for better grip. A number of producers make ACR style bits of varying quality.

FYI: The ACR design is licensed out by Phillips for who ever wants to use it and is found on a number of other brands. One of the reasons Snap-On and others are short is they don't manufacture all their tools and have to rely on other vendors. Never been a Snap-On fan except for some specialty tools but when possible we would find out who supplied Snap-On then go buy their brand at a substantial savings. The OPs bits being one them.Thanks, pretty sure the snap on tips have used that for many years. Now we can't get snap on scewdrivers?? What is this world coming to?

I HATE when folks put screws back in holes . Almost as much as when Mooney and Cherokee owners leave on the floor when I’m on a Creeper? Sticking your hand in the hole can result in blood and scars!

My thought is to push screws into a cardboard “ template” so you can tell where odd ones go. If all screws are not identical and a big screws is put in a small nut the outcome is not good.

i recall a mag article; “ Getting the shaft in the shop?” where owners of older Mooneys were told to check for Tech’s air or batt driver. You are going to buy them one anyway.

Removing paint from screw also helps engagement.

My thought is to push screws into a cardboard “ template” so you can tell where odd ones go. If all screws are not identical and a big screws is put in a small nut the outcome is not good.

i recall a mag article; “ Getting the shaft in the shop?” where owners of older Mooneys were told to check for Tech’s air or batt driver. You are going to buy them one anyway.

Removing paint from screw also helps engagement.

LesGawlik

Line Up and Wait

- Joined

- May 6, 2006

- Messages

- 973

- Display Name

Display name:

Good Guy

ACR anti-camout removal.

Years go, the Rigid ACR screwdrivers were considered the best. I bought a set and have used them for 20 years.

A small touch of valve lapping compound on the bit may help.

Years go, the Rigid ACR screwdrivers were considered the best. I bought a set and have used them for 20 years.

A small touch of valve lapping compound on the bit may help.

Last edited:

- Joined

- Apr 5, 2017

- Messages

- 3,886

- Location

- hopefully not at work

- Display Name

Display name:

Meet the Fokkers

Right but what I think is that an impact bit probably isn’t appropriate for hand use on a plane

If anybody has any information regarding this...now I'm curious.

ktup-flyer

En-Route

I LOVE their Zyklop Mini ratchets. Must have in the tool box for me, along with everything Knipex makesWe buy nothing but Wera tips at work these days. Don't know about their Phillips ones, as all ours are Torx. One thing that will help no matter who's tips you get, is grind off the point, so the end of the tip is a a bit flatter.

Craig

Cleared for Takeoff

I LOVE their Zyklop Mini ratchets. Must have in the tool box for me, along with everything Knipex makes

One of our labs had to set up a torture test rig and do a lot of testing before they settled on the Wera's. We were going thru Apex's at the rate of hundreds to thousands every week at the start of the program. Mostly due to the T-20 either deforming after a few uses, or the tips shattering, with some getting tossed due to excess wear.

We ran into the same problem with drill bits early in the program. We went thru what would have been more than a year's worth on the other program, in a matter of months on this one. Took a while to find the right combination of drill angle, material, twist rate, coatings and edge geometry to get thru the material reliably and economically.

donjohnston

Pattern Altitude

This sucker right here!about a year ago I bought a battery screwdriver, I think it is a dewalt? Yellow...it is handy for disassembly and is light enough that you do develop a feel using it. Never thought I'd like but I do. Can't find a picture of it.

I've had one of these for about five years. Perfect for pulling all the screws on a Cessna 182 during annuals. And once you've used it a little, you get a really good feel on how tight to hold it when putting the screws back in. Great for installing cabinet hinges (I also use it for drilling pilot holes), electrical outlets, switches, etc.

https://www.dewalt.com/product/dcf682n1/8v-max-gyroscopic-inline-screwdriver?tid=578601

Attachments

Mxfarm

Line Up and Wait

I’ll have to try Wera, once I started using Wiha, I quit looking. I’m a bit compulsive about Phillips, screws and bits, keep supply and change scarred ones out. I’ve threatened to switch to button head socket head cap screws, but would probably have the same problem….

Dan Thomas

Touchdown! Greaser!

- Joined

- Jun 16, 2008

- Messages

- 11,228

- Display Name

Display name:

Dan Thomas

I used small cordless electric drills for many years. The key is "small." 12 volts max. You use only as much torque as you need to remove the screws, and use hard bits. Impact bits are softer to prevent shattering, and their points wear to sloped surfaces that jump out of the socket. Snap-On's bits have little gripper treads on them. Work well, and as someone else mentioned, a bit of valve grinding compound (the finer stuff, not coarse) aids in gripping stuck screws.

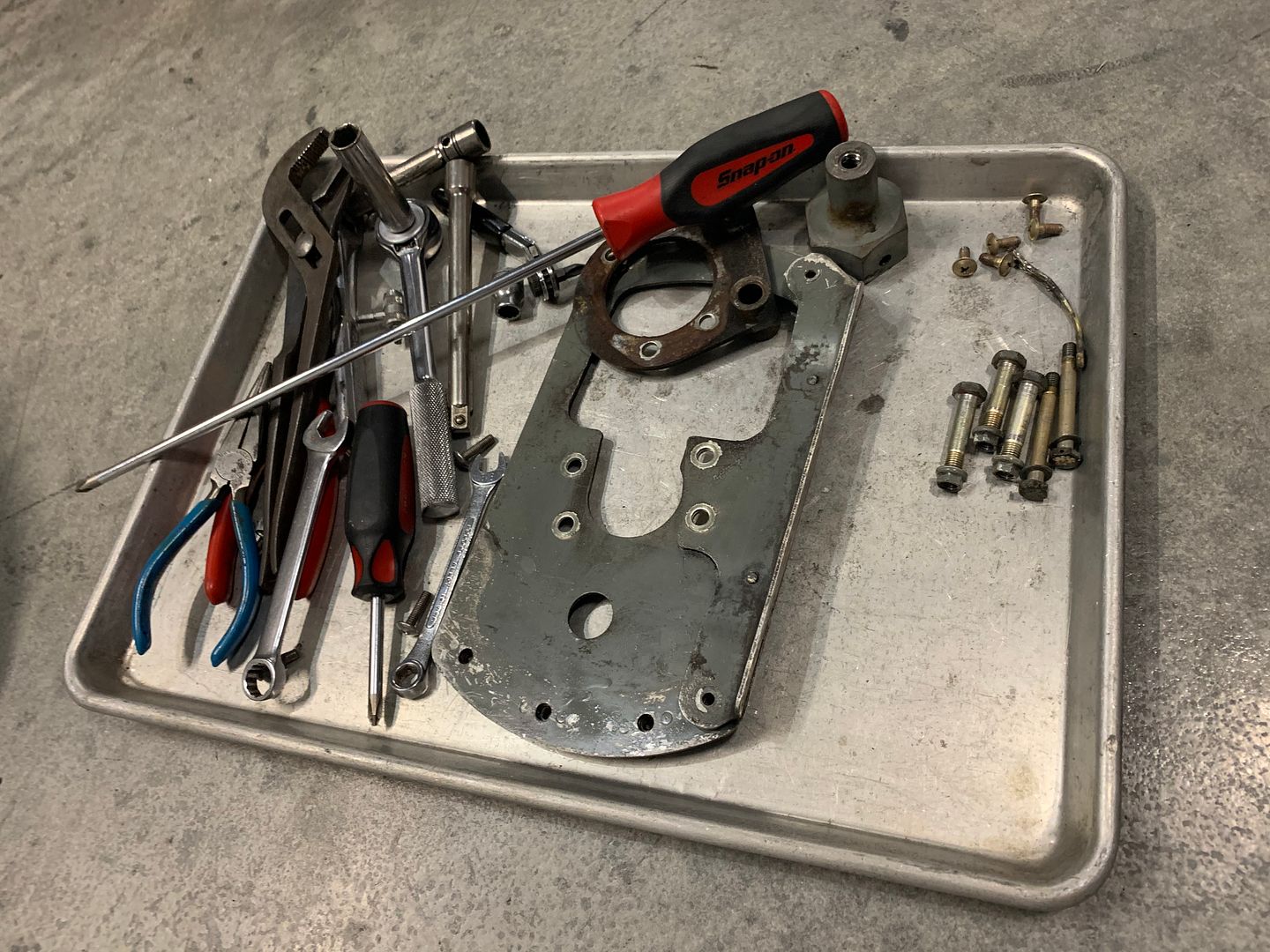

When the shop rate is $120 an hour, the airplane's owner doesn't want the mechanic spending four hours removing all those screws by hand, and another four hours or more reinstalling them all. I used old muffin baking pans from the thrift shops to keep screws sorted. Saves a lot of time. Bagging adds time. You can run strips of masking tape along the muffin pans to write the screw locations on.

When the shop rate is $120 an hour, the airplane's owner doesn't want the mechanic spending four hours removing all those screws by hand, and another four hours or more reinstalling them all. I used old muffin baking pans from the thrift shops to keep screws sorted. Saves a lot of time. Bagging adds time. You can run strips of masking tape along the muffin pans to write the screw locations on.

Last edited:

That’s the one! Works well I put a long driver and extension to give me the feel of a long screwdriver.This sucker right here!

View attachment 112257

I've had one of these for about five years. Perfect for pulling all the screws on a Cessna 182 during annuals. And once you've used it a little, you get a really good feel on how tight to hold it when putting the screws back in. Great for installing cabinet hinges (I also use it for drilling pilot holes), electrical outlets, switches, etc.

https://www.dewalt.com/product/dcf682n1/8v-max-gyroscopic-inline-screwdriver?tid=578601

As far snap on, Matco and the rest, I buy from them because they come to my shop and some are my customers and friends, they do business with me. Probably could find something’s cheaper elsewhere but it is not worth it sometimes.

bluerooster

Pattern Altitude

- Joined

- Nov 28, 2011

- Messages

- 2,087

- Display Name

Display name:

shorty

I want one so bad I can taste it. But there are none available at the local suppliers.This sucker right here!

View attachment 112257

I've had one of these for about five years. Perfect for pulling all the screws on a Cessna 182 during annuals. And once you've used it a little, you get a really good feel on how tight to hold it when putting the screws back in. Great for installing cabinet hinges (I also use it for drilling pilot holes), electrical outlets, switches, etc.

https://www.dewalt.com/product/dcf682n1/8v-max-gyroscopic-inline-screwdriver?tid=578601

bluerooster

Pattern Altitude

- Joined

- Nov 28, 2011

- Messages

- 2,087

- Display Name

Display name:

shorty

The Snap-on guy lives not far from the shop, If I need something I can give him a call, and he'll stop by even if it's not his regular day.As far snap on, Matco and the rest, I buy from them because they come to my shop and some are my customers and friends, they do business with me. Probably could find something’s cheaper elsewhere but it is not worth it sometimes.

donjohnston

Pattern Altitude

Amazon. You won't have it today, but you should have it before the end of the week.I want one so bad I can taste it. But there are none available at the local suppliers.

https://www.amazon.com/DEWALT-DCF682N1-Gyroscopic-Inline-Screwdriver/dp/B011WRUODC?th=1

Or any of the other sources.

https://www.factoryauthorizedoutlet...h-0-430-rpm-gyroscopic-inline-screwdriver-kit

https://www.acmetools.com/8v-max-inline-gyro-screwdriver-dcf682n1/885911356602.html

Tarheelpilot

Final Approach

- Joined

- Dec 5, 2010

- Messages

- 7,480

- Location

- North Carolina once again.

- Display Name

Display name:

Tarheelpilot

https://www.browntool.com/Listview/tabid/344/CategoryID/269/Level/a/Default.aspxSnap on ACR’s are $4.50 each but back ordered.

I got to open up my 182 for her IA, only about 2,000 screws to pull and bag.

Any recommendations?

less than a dollar and same quality of the snap on in my opinion. I buy them in lots of 100. Just make sure you get the ACR Phillips.

nrpetersen

Line Up and Wait

Occasionally wash and dry any driver tips in lacquer thinner or similar solvent to remove any traces of lubrication or anti-seize.

Mxfarm

Line Up and Wait

ordered Sunday from A’zon and arrived Wed - very cool….Amazon. You won't have it today, but you should have it before the end of the week.

https://www.amazon.com/DEWALT-DCF682N1-Gyroscopic-Inline-Screwdriver/dp/B011WRUODC?th=1

Or any of the other sources.

https://www.factoryauthorizedoutlet...h-0-430-rpm-gyroscopic-inline-screwdriver-kit

https://www.acmetools.com/8v-max-inline-gyro-screwdriver-dcf682n1/885911356602.html

https://www.mcmaster.com/screwdrivers/for-drive-style~jis/driver-style~bit/JIS Japan Industrial Standard and never look back!

The #2 JIS is by far the most useful for me and they last a long time. For that reason I stay away from the sets. They can also be found on the "jungle" site from time to time but McMaster's price is pretty good.

Spring Ford

Line Up and Wait

- Joined

- Jul 11, 2018

- Messages

- 762

- Display Name

Display name:

SpringFord

You folks do know that JIS, Phillips and Pozidriv are different profiles?

JIS bits - JIS screws

etc

Give me Robinson any day

I believe JIS screws are supposed to have a little dot and pozidriv screws always have a vestigial additional cross at 45 degrees. Pozidriv screwdrivers have a matching feature between the main blade elements and so can always be identified.

I suspect this is why, 30 years ago, everyone had such difficulty with the screws on Japanese motorcycles. No one knew that their Phillips screwdrivers were the wrong shape for the JIS screws. No one had heard of JIS.

https://en.wikipedia.org/wiki/List_of_screw_drives

JIS bits - JIS screws

etc

Give me Robinson any day

I believe JIS screws are supposed to have a little dot and pozidriv screws always have a vestigial additional cross at 45 degrees. Pozidriv screwdrivers have a matching feature between the main blade elements and so can always be identified.

I suspect this is why, 30 years ago, everyone had such difficulty with the screws on Japanese motorcycles. No one knew that their Phillips screwdrivers were the wrong shape for the JIS screws. No one had heard of JIS.

https://en.wikipedia.org/wiki/List_of_screw_drives

Last edited:

Dan Thomas

Touchdown! Greaser!

- Joined

- Jun 16, 2008

- Messages

- 11,228

- Display Name

Display name:

Dan Thomas

Robertson. A Canadian inventor. And even that screw has its drawbacks. The hole has a taper to it, and a bit that has worn corners will pop out of it. The square hole weakens the head's attachment to the screw shank, and I have had the heads pop off. Still, much better than the Phillips. I think the Torx is likely the best. The automakers think so, too.Give me Robinson any day

]

https://www.thomasnet.com/articles/hardware/robertson-screwdriver-history/

Stihl has gone all in on Torx T27 on all their equipment. As usual, B&S is still trying to figure it out. Briggs still has a combination of T25, metric and SAE. Lots of fun to work on.

Kristin

Pattern Altitude

- Joined

- Dec 1, 2013

- Messages

- 1,646

- Location

- Twin Cities

- Display Name

Display name:

Kristin (The Aviatrix)

My go-to. Have used this and its predecessor for 30+ years.

https://www.milwaukeetool.com/Products/Power-Tools/Fastening/2101-22

Zantop Air Transport operated an aircraft called the AW-650 Argosy. This British cargo aircraft used British Standard and Whitworth Standard hardware extensively.

It utilized screws that were slotted. However; there was also a drilled hole in the center of the slot. The crew always used standard flat screwdrivers but I have wondered if there was a special bit that used the hole to stabilize the bit.

It utilized screws that were slotted. However; there was also a drilled hole in the center of the slot. The crew always used standard flat screwdrivers but I have wondered if there was a special bit that used the hole to stabilize the bit.