robertthoyer

Filing Flight Plan

- Joined

- Dec 21, 2015

- Messages

- 6

- Display Name

Display name:

cowboy

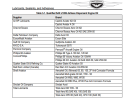

Since older Lycoming engines have flat tappets and wear more on cam and lifters I have started to add a pint of this product at oil change. I use victory xc 20w50 which has AW lyc additive also. Can there be any harm having too much zinc. On my latest oil analysis I see an increase in iron fe from 85. To 133.47. Checking the filter element shows no chips or metal or anything very clean. Sump screen same. The engine has over 5000 hrs SN. And 360 hrs SMO. Oil burn is a Qt/15hrs. The eng parameters based on my MV 50 eng monitor all good low temps cht mid 300s egt below 1450.

Not sure if zinc can increase the iron. Which its suppose to decrease iron ppm. Prior to using zinc additive the levels were 68, then 85 and now 133

Not sure if zinc can increase the iron. Which its suppose to decrease iron ppm. Prior to using zinc additive the levels were 68, then 85 and now 133