Gone Flyin

Pre-takeoff checklist

- Joined

- Nov 30, 2020

- Messages

- 120

- Display Name

Display name:

Gone Flyin

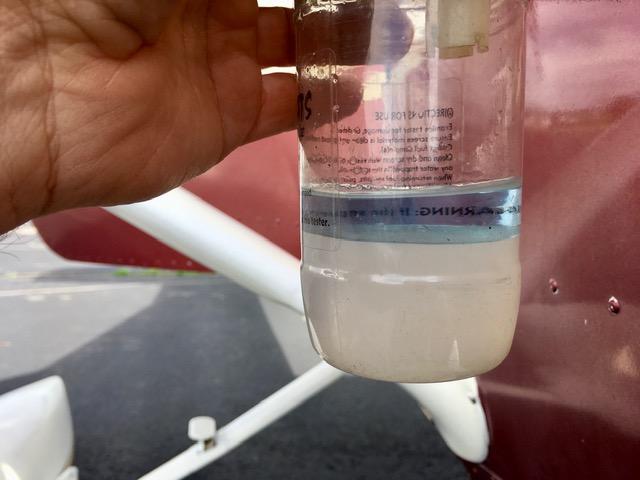

The day my Cessna 150 was delivered (ferried) to my airport where I was to take my training, I decided to take fuel samples of the wings, the gascolator and the sump drain port.

This is what came out of the sump drain.

This, after I paid a handsome some for an annual. This caused me to get religion quick and always do a proper fuel inspection before every flight.

In fact, the Cessna POH (and I'm assuming all plane manufacturers) requires the pilot to keep sampling the fuel until there is no presence of water, whatsoever.

My standard technique is to use the Gats Jar and fill it from each of the four ports. That gets me at least 12 ounces each time. I then pour that off into a container through a 200 mesh (74 microns) stainless steel screen. The screen lets the fuel pass but will block the water and any contaminants.

It's the same as the screen used in the Gats Jar.

The screen is held in one of those knitting rings. You can get them at any crafts store for a few dollars. The ring just sits in a funnel inside the container.

I keep sampling this way until I have no water in the jar. Usually, this will take two samples. If its been very humid, I may go into a third, just to be sure.

Then, I set a funnel into one of my tanks and pour the fuel... by now at least a quart or more... back into the tank... again, through the mesh screen.

Works for me.

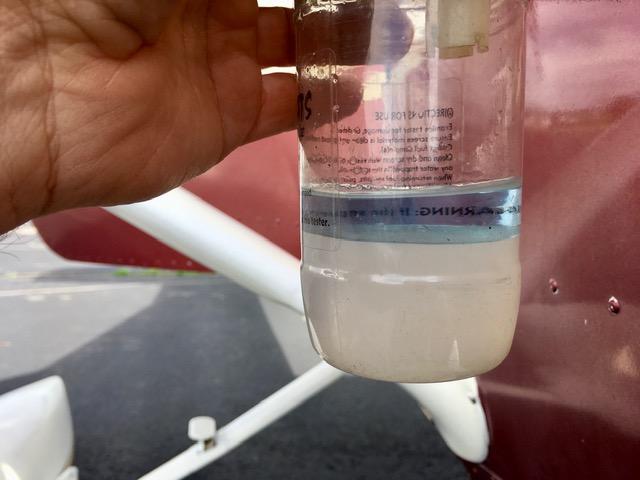

This is what came out of the sump drain.

This, after I paid a handsome some for an annual. This caused me to get religion quick and always do a proper fuel inspection before every flight.

In fact, the Cessna POH (and I'm assuming all plane manufacturers) requires the pilot to keep sampling the fuel until there is no presence of water, whatsoever.

My standard technique is to use the Gats Jar and fill it from each of the four ports. That gets me at least 12 ounces each time. I then pour that off into a container through a 200 mesh (74 microns) stainless steel screen. The screen lets the fuel pass but will block the water and any contaminants.

It's the same as the screen used in the Gats Jar.

The screen is held in one of those knitting rings. You can get them at any crafts store for a few dollars. The ring just sits in a funnel inside the container.

I keep sampling this way until I have no water in the jar. Usually, this will take two samples. If its been very humid, I may go into a third, just to be sure.

Then, I set a funnel into one of my tanks and pour the fuel... by now at least a quart or more... back into the tank... again, through the mesh screen.

Works for me.