Stevel

Pre-takeoff checklist

I was taught that a boxer engine (so named by Hitler) had both pistons on one side coming up together and then both pistons on the other side coming up together. As I vaguely remember it, it makes the design of an "interference free" engine easier. I've never seen an aircraft engine like that.

That's not what I was taught. I was told that it was the term for opposed engines that have the pistons in the cylinders that are opposite each other travelling inward toward the center at the same time as each other and then outward at the same time as each other. The "boxer" reference was from the similarity of the pistons' motions to the act of a boxer punching his fists together.

These engines would have the inertial forces balanced by the opposing cylinder, and the firing would be even at 360 degree spacing for a 4-cycle and simultaneous for 2-cycle.

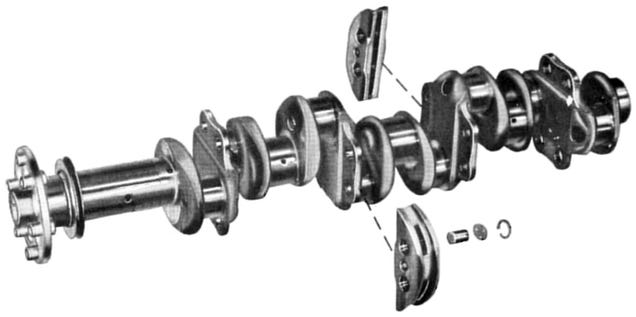

Having all of the pistons on one side coming in while all of them on the other were going out would double up on the inertial forces, and would be very difficult to balance (balance shafts and such), and would be brutal on the main bearings. These would have two rods per journal, like so many V-configuration engines, and all of the journals in line with each other. The timing on an opposed pair would be 540 degrees and then 180 degrees, so even-firing would only be possible in configurations with multiples of four cylinders (no two or six cylinder option).

I realize that my discussion of the shortcomings of such an engine have nothing to do with the name of that engine, but think about it for a minute. How would the name of such an ungainly contraption, few examples of which have been attempted, gotten so ingrained into the popular lexicon?

EDIT: I took your advice to read the "true-boxer" info, and was expecting to come back with a "Well, I'll be damned, whooda thunkit" retraction to the above, but was pleasantly surprised to see that I was not wrong.

Please re-read it more carefully, and you will find that it supports the assertion that every opposed aircraft engine in the group that you think of as "standard" or "normal", is in fact a "boxer". The fact that aviation professionals prefer to use another term that is a better fit within the group of terms that are used to describe other engines ("O", "I", "R", "V") doesn't refute that.

Last edited: