Took my plane out today for a cross country flight. Flew about 3 hours. Ground temps were between 85 and 95, flew pretty low, about 2500-3000 MSL. I noticed oil temp was running a bit hotter than normal. It wasnt in the red but I would say it was 90% of the way there. Pressure was good (top of green arc), and the temp didn't change much when I tried things like running full rich, descending, changing power, etc so I wasnt horribly concerned, but of course it is some food for thought here. Should I even worry about this, or is there anything I should check? Temps seemed to drop to roughly middle of green arc after landing and taxiing.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Operating temp question

- Thread starter Gwt9678

- Start date

sourdough44

En-Route

I wouldn’t be to concerned, under those conditions/temps. It sounds like you only have an oil temp gauge? In general CHT temps are more meaningful, but all go into the mix of monitoring.

With routine flying one develops history with what to expect. At 95 degrees one would normally expect higher temps indicated. Flying higher is one way to cool down.

With routine flying one develops history with what to expect. At 95 degrees one would normally expect higher temps indicated. Flying higher is one way to cool down.

Thanks! Yes at this point I'm only running on the original 1966 oil temp gauge. I will hopefully be adding at least a basic digital cht/egt/oil temp at annual this year so I can get a better idea of what's going on.

Based on what you’ve written, I wouldn’t worry, it sounds normal to me.

Stewartb

Final Approach

Green is green. Red is red. Better yet, test your temp sender to find out exactly what "90%" represents.

sarangan

Pattern Altitude

- Joined

- Jun 7, 2008

- Messages

- 1,896

- Display Name

Display name:

Andrew, CFI-I

I've heard this "Green is green. Red is red.", but sorry, I don't agree. If the gauge is not where it usually is, you should investigate. That is the purpose of having an analog gauge there, instead of an on/off light bulb. Oil pressure should also read lower than normal when the temperature is higher than normal. If the higher temperature correlates to a higher outside air temperature, then make a mental note and move on, but I would still be keeping an eye on it instead of assuming everything is just fine because it is all in the green.

Stewartb

Final Approach

Analog gauges don't tell you anything other than go or no-go. Any variation in where the needle falls in the green isn't useful information UNLESS you test and mark your gauge in order to understand what the needle position-temperature relationship is. Short of doing that? Anything shy of the red line is in the acceptable operating temperature range. If you want accurate information? Get an accurate gauge.

By the way, if you buy a new sender for that analog instrument you can expect to to register temps differently than the one it replaced. In decades past I've sorted through senders to find one that placed the needle in a comfortable position while another would crowd the red line. I don't use analog gauges anymore.

By the way, if you buy a new sender for that analog instrument you can expect to to register temps differently than the one it replaced. In decades past I've sorted through senders to find one that placed the needle in a comfortable position while another would crowd the red line. I don't use analog gauges anymore.

High oil temperatures nine times out of ten turns out to be LOW OIL LEVEL. This is your sign that you've got a leak (or just didn't fill it properly). The pressure will stay up there in a normally functioning engine until you're low on oil. A low oil pressure usually is a sign of an oil too low in visconsity for the temperature (like running a straight 40 in very hot conditions).

James331

Ejection Handle Pulled

- Joined

- Apr 18, 2014

- Messages

- 20,309

- Display Name

Display name:

James331

Green is green. Red is red. Better yet, test your temp sender to find out exactly what "90%" represents.

No.

Every plane has where it normally runs temp/pressure/etc, even if it “in the green” if it’s abnormal for that plane it’s something you’ll want to have checked out.

I’d rather nip things in the bud BEFORE they go out of the green.

Sorry Stewart, James and Andrew are correct. Green is not just green.Green is green. Red is red. Better yet, test your temp sender to find out exactly what "90%" represents.

Back when I had my old Volvo, the needle on the temp gauge would always remain steady in the center. Anytime it went beyond that band, I knew something was amiss, even though it was still technically within the operating range. Usually it was a simple correction, like being low on coolant. There’s a reason for something to be running hotter than it typically does and it’s best to figure out why, rather than just say that it’s okay because it’s still within limits. Airplanes are no different.

Dan Thomas

Touchdown! Greaser!

- Joined

- Jun 16, 2008

- Messages

- 10,754

- Display Name

Display name:

Dan Thomas

Knowing what make/model of airplane, and what engine, would help.

1966 and thereabouts saw a lot of mechanical oil temp gauges. They used a bulb in the engine that had a tiny tube that led to the gauge, which was really a pressure gauge calibrated in degrees. The bulb, tube and bourdon mechanism in the gauge were all filled with oil and the whole thing sealed as a unit. When the oil got hot it expanded and pushed the gauge needle up.

Sometimes that bulb has to come out when the oil screen is cleaned. If it got dented, it could make the gauge read higher.

If it's an electric gauge, a poor engine ground can drive the reading up. The alternator/generator are pumping electrons into the engine case and thence via a ground strap to the airframe. When the path gets dirty/corroded/loose/whatever, resistance goes up and the electrons try finding other paths, like through control cables, primer lines, as well as via the temp sender (which is grounded to the engine case), through the gauge to the bus and battery and into ground at that point. In other words, it enhances the sender's flow to the gauge, driving the gauge up.

Old airplanes are fun and profitable. There is no such thing as a cheap old airplane.

1966 and thereabouts saw a lot of mechanical oil temp gauges. They used a bulb in the engine that had a tiny tube that led to the gauge, which was really a pressure gauge calibrated in degrees. The bulb, tube and bourdon mechanism in the gauge were all filled with oil and the whole thing sealed as a unit. When the oil got hot it expanded and pushed the gauge needle up.

Sometimes that bulb has to come out when the oil screen is cleaned. If it got dented, it could make the gauge read higher.

If it's an electric gauge, a poor engine ground can drive the reading up. The alternator/generator are pumping electrons into the engine case and thence via a ground strap to the airframe. When the path gets dirty/corroded/loose/whatever, resistance goes up and the electrons try finding other paths, like through control cables, primer lines, as well as via the temp sender (which is grounded to the engine case), through the gauge to the bus and battery and into ground at that point. In other words, it enhances the sender's flow to the gauge, driving the gauge up.

Old airplanes are fun and profitable. There is no such thing as a cheap old airplane.

Last edited:

NordicDave

En-Route

High oil temperatures nine times out of ten turns out to be LOW OIL LEVEL.

On every Lycoming, Continental, Garret, and Pratt & Whitney engine that I fly, the oil temp runs higher when it is hot out. At air temps of 85-95f, it is normal for the oil to run warmer than it would, for example, at 65-75f. If you don't have a baseline from past experience flying in those temps, see what the POH says etc., and get more familiar with it. If it is running warmer than it should, consult a mechanic familiar with your engine and airframe.

Paulie

Line Up and Wait

Recognizing a trend is important. I would start recording the ambient and oil temps. This is what’s nice about the new gauges that record data, you can download and see trends easily.Green is green. Red is red. Better yet, test your temp sender to find out exactly what "90%" represents.

Paulie

Line Up and Wait

Not true, even if you don’t know exactly the temp something is different. Hardly a go no go gauge.Analog gauges don't tell you anything other than go or no-go. Any variation in where the needle falls in the green isn't useful information UNLESS you test and mark your gauge in order to understand what the needle position-temperature relationship is. Short of doing that? Anything shy of the red line is in the acceptable operating temperature range. If you want accurate information? Get an accurate gauge.

By the way, if you buy a new sender for that analog instrument you can expect to to register temps differently than the one it replaced. In decades past I've sorted through senders to find one that placed the needle in a comfortable position while another would crowd the red line. I don't use analog gauges anymore.

Clip4

Final Approach

Check the condition of the baffling.

Recognizing a trend is important. I would start recording the ambient and oil temps. This is what’s nice about the new gauges that record data, you can download and see trends easily.

If things are DIFFERENT figure out why, even if they are still in the green. The worst thing you want (NASA learned about this the hard way) is just to accept the new trend as normal.

kyleb

Final Approach

- Joined

- Jun 13, 2008

- Messages

- 7,554

- Location

- Marietta, GA

- Display Name

Display name:

Drake the Outlaw

High oil temperatures nine times out of ten turns out to be LOW OIL LEVEL.

I disagree with this. As long as the engine has enough oil in it to avoid unporting, more oil doesn't materially impact cooling.

Once the engine is up to steady state operating conditions, oil temp is going to stabilize at a point where the energy shed by the oil cooler is equal to the energy added to the oil during operation. Any extra oil above the minimum required amount just sits in the sump briefly before being recirculated and is neither absorbing or giving off heat while it is in the sump.

High oil temperatures are usually caused by undersized or dirty oil coolers, by poor airflow through the cooler, or by some sort of engine problem.

We carry 6 or 8 (or 10 or 12) quarts in engines that would run with a fraction of that as insurance against oil consumption or leakage.

James331

Ejection Handle Pulled

- Joined

- Apr 18, 2014

- Messages

- 20,309

- Display Name

Display name:

James331

I disagree with this. As long as the engine has enough oil in it to avoid unporting, more oil doesn't materially impact cooling.

Once the engine is up to steady state operating conditions, oil temp is going to stabilize at a point where the energy shed by the oil cooler is equal to the energy added to the oil during operation. Any extra oil above the minimum required amount just sits in the sump briefly before being recirculated and is neither absorbing or giving off heat while it is in the sump.

High oil temperatures are usually caused by undersized or dirty oil coolers, by poor airflow through the cooler, or by some sort of engine problem.

We carry 6 or 8 (or 10 or 12) quarts in engines that would run with a fraction of that as insurance against oil consumption or leakage.

Depends on how low, mine holds 12, I keep it at 10, zero difference in temps. Now I’m sure if I let it get down to like 5, it would still lube the engine but temps would be higher.

Sorry, I must disagree to your disagreement. The oil quantity to temperature issue is well known. Understand that your "air cooled" engine is to some extent an "oil cooled" engine. Decrease the amount of oil available, the oil temps go up.

Yes, as far as LUBRICATION is concerned, your 12 quart engine can run on 3 or 4. But you will expect the oil temps to go up while doing so. The 12 quart engine may throw oil down to 9 or 10. This is because the 12 quarts is an "over filled" state that's a relic of the certification requirements for the engine.

Yes, as far as LUBRICATION is concerned, your 12 quart engine can run on 3 or 4. But you will expect the oil temps to go up while doing so. The 12 quart engine may throw oil down to 9 or 10. This is because the 12 quarts is an "over filled" state that's a relic of the certification requirements for the engine.

kyleb

Final Approach

- Joined

- Jun 13, 2008

- Messages

- 7,554

- Location

- Marietta, GA

- Display Name

Display name:

Drake the Outlaw

Sorry, I must disagree to your disagreement. The oil quantity to temperature issue is well known. Understand that your "air cooled" engine is to some extent an "oil cooled" engine. Decrease the amount of oil available, the oil temps go up.

Provide a logical reason why you believe that.

Where is the extra oil? The sump. Extra oil sitting in the sump does not cause the oil cooler to reject more heat.

1RTK1

Pattern Altitude

From what I was taught the numbers in a car are 60% water and 40% oil for cooling, air cooled engines oil is more than 40%. Running any engine low on oil will increase temps, by how much, don’t know, never tried it.

Last edited:

Simple thermodynamics. If you have X calories of heat generated, the more liquid you have to heat, the cooler it will be.Provide a logical reason why you believe that.

Where is the extra oil? The sump. Extra oil sitting in the sump does not cause the oil cooler to reject more heat.

And the oil cooler is not the only LOSS of heat in the oil system.

Stewartb

Final Approach

I’ve never recognized any oil temp change based on quantity but I’ve never run below 6 in my Cubs or 8 in my Cessna. In fact most 520s in Cessnas have a 9qt mimimum, don’t they? That’s an airworthiness item, isn’t it? What I do see, and is probably the answer to the OP, is higher oil temps in higher ambient temps. The oil cooler performance has a curve based on outside air temps. It may stay in a relatively small range of oil temps until you find it’s OAT threshold where your oil temps will go up quickly. Are you familiar with your plane’s curve? So it goes with analog gauges, too. My bigger point about analog gauges stated earlier is UNLESS you’ve made the effort to identify what your sweep needle’s values are? A change it the needle position doesn’t represent a known value so any interpretation of it is a guess. Put a value to it before you get too wound up about it. Compare that value or change to other KNOWN values, like OAT. It’ll probably explain the trend.

I can manipulate oil temp upwards my manipulating fuel flow to increase CHT. Another example of using a known values (fuel flow, CHT) to explain oil temp trends.

I can manipulate oil temp upwards my manipulating fuel flow to increase CHT. Another example of using a known values (fuel flow, CHT) to explain oil temp trends.

Dan Thomas

Touchdown! Greaser!

- Joined

- Jun 16, 2008

- Messages

- 10,754

- Display Name

Display name:

Dan Thomas

The sump convects heat into the cooling air. It's not just the oil cooler that dumps the heat. In fact, many smaller engines don't have oil coolers, relying entirely on the sump to cool the oil.Provide a logical reason why you believe that.

Where is the extra oil? The sump. Extra oil sitting in the sump does not cause the oil cooler to reject more heat.

Now, if there's less oil, it circulates more frequently. If the pump is moving six quarts a minute, and there's six quarts there, it will theoretically take a minute to circulate the whole works. Cut that to three quarts and it only takes 30 seconds. The oil is being heated twice as often and spending half the time in the sump, and the area contacted by the oil in the sump is also smaller. It's going to get hotter.

bnt83

Final Approach

In fact most 520s in Cessnas have a 9qt mimimum, don’t they?

Just looked up a T210R POH, capacity is 10 quarts, says do not operate with less than 7 quarts.

Cessna 210L, capacity is 10 quarts, do not operate with less than 7

O320 equipped 172, 8 quart capacity and POH says do not operate with less than 6, way more than the engine TCDS says.

This TCM Operator's Manual doesn't match the dash number of either 520 in those airplane but it is interesting that only two quarts are unusable.

http://www.csobeech.com/files/TCM-IO520-OpsInstallManual.pdf

Cessna 172 with O-320-E2D POH "Do not operate with less than 6 quarts"

FAA TCDS for the E2D

Last edited:

bnt83

Final Approach

The sump convects heat into the cooling air. It's not just the oil cooler that dumps the heat. In fact, many smaller engines don't have oil coolers, relying entirely on the sump to cool the oil.

Now, if there's less oil, it circulates more frequently. If the pump is moving six quarts a minute, and there's six quarts there, it will theoretically take a minute to circulate the whole works. Cut that to three quarts and it only takes 30 seconds. The oil is being heated twice as often and spending half the time in the sump, and the area contacted by the oil in the sump is also smaller. It's going to get hotter.

Exactly why on really hot days I add a quart to where I normally run at. I think its pretty noticeable on an O320.

flyingbrit

Pre-takeoff checklist

- Joined

- Apr 21, 2014

- Messages

- 411

- Display Name

Display name:

flyingbrit

Not quite. These type of gauges have the bulb filled with ether, AKA starting fluid. It's not the liquid expanding with temperature, but rather the change in vapor pressure which causes the needle to move.1966 and thereabouts saw a lot of mechanical oil temp gauges. They used a bulb in the engine that had a tiny tube that led to the gauge, which was really a pressure gauge calibrated in degrees. The bulb, tube and bourdon mechanism in the gauge were all filled with oil and the whole thing sealed as a unit. When the oil got hot it expanded and pushed the gauge needle up.

kyleb

Final Approach

- Joined

- Jun 13, 2008

- Messages

- 7,554

- Location

- Marietta, GA

- Display Name

Display name:

Drake the Outlaw

Thanks to BNT83 for posting the TCDS for the O-320.

The pertinent information, which he circled in red, is that Lycoming recommends you not take off with less than 6 quarts of oil in your O-320. On the other hand, Lycoming divulges that the engine will safely operate on two quarts. Why the difference?

It ain't cooling. It is oil consumption.

An extended range (52? gallon capacity) C-172 or a 160 horse Cherokee (50 gallons) has sufficient fuel to fly ~6 hours at ~65% power (roughly 7.5 GPH). Lycoming's 6 quart minimum for the O-320 prevents you from running low (or out) of oil before you run out of gas on your 6 hour flight. (Why anyone would want to spend 6 hours in a 172 is another issue entirely.)

Lycoming's published limit for maximum oil consumption is HP x .006 x 4 /7.4 = .52 Quarts/Hr for a 160 HP engine. So if you launch with 6 quarts of oil, consume oil at the maximum allowable rate (.52 QPH), and fly for 6 hours, you'll be down to just under 3 quarts of oil at the end of your flight, which is comfortably above the 2 quart "safe operating" minimum. This means your endurance is limited by fuel, rather than oil. That's what Lycoming wants and is how they determine the minimum "takeoff" oil quantity. Throw ferry tanks in the back and all bets are off!

To the idea that the sump rejects heat.

The pertinent information, which he circled in red, is that Lycoming recommends you not take off with less than 6 quarts of oil in your O-320. On the other hand, Lycoming divulges that the engine will safely operate on two quarts. Why the difference?

It ain't cooling. It is oil consumption.

An extended range (52? gallon capacity) C-172 or a 160 horse Cherokee (50 gallons) has sufficient fuel to fly ~6 hours at ~65% power (roughly 7.5 GPH). Lycoming's 6 quart minimum for the O-320 prevents you from running low (or out) of oil before you run out of gas on your 6 hour flight. (Why anyone would want to spend 6 hours in a 172 is another issue entirely.)

Lycoming's published limit for maximum oil consumption is HP x .006 x 4 /7.4 = .52 Quarts/Hr for a 160 HP engine. So if you launch with 6 quarts of oil, consume oil at the maximum allowable rate (.52 QPH), and fly for 6 hours, you'll be down to just under 3 quarts of oil at the end of your flight, which is comfortably above the 2 quart "safe operating" minimum. This means your endurance is limited by fuel, rather than oil. That's what Lycoming wants and is how they determine the minimum "takeoff" oil quantity. Throw ferry tanks in the back and all bets are off!

To the idea that the sump rejects heat.

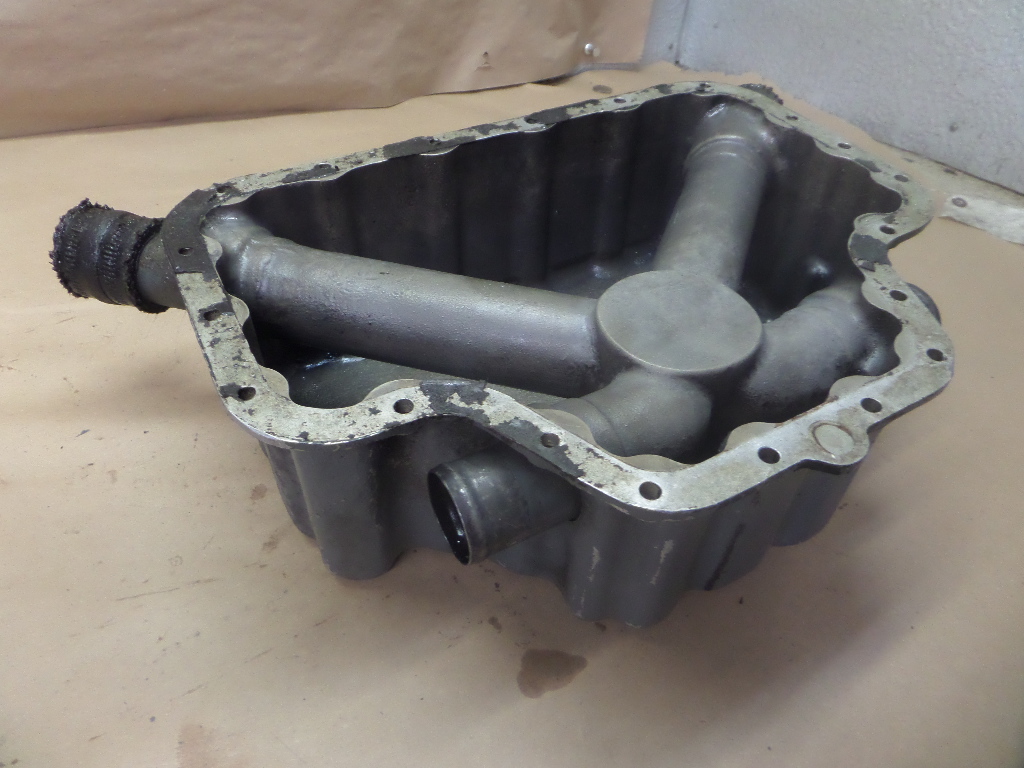

It does. No doubt. But does that rate change in a meaningful way with the addition of a quart of oil? I don't think so. A quart of oil is ~58 cubic inches. I'm guessing a typical 4 cylinder Lycoming sump has a footprint that is 12" x 12" or 144 square inches. The IO-540 sump in my garage has a cross section slightly larger - about 13.5" x 12" or 162 square inches. Where this is going is a quart of oil increases the oil level in the 4 cylinder's sump by 58 in^3/144 in^2 = 0.4 in. That means the additional quart of oil inside the sump touches a band 0.4" high x the 48" perimeter of the sump. Roughly 19 in^2. How much additional heat transfer is 19 in^2 of internal surface contact going to create? Not much, since the sump is already "at temp" due to the great heat conductive properties of aluminum. Also, the area on the outside of the sump exposed to cooling air won't change, and that cooling air that impinges the sump ain't exactly cool in the first place, because it has passed through the cylinder fins and around the exhaust headers. So, a quart of oil won't do anything meaningful. (Note, I used the word meaningful in my original post disputing the idea that oil quantity changes oil temperature.)

Dan Thomas

Touchdown! Greaser!

- Joined

- Jun 16, 2008

- Messages

- 10,754

- Display Name

Display name:

Dan Thomas

Have you ever had a Lycoming apart? Ever studied the parts manual or overhaul manual?To the idea that the sump rejects heat.

It does. No doubt. But does that rate change in a meaningful way with the addition of a quart of oil? I don't think so. A quart of oil is ~58 cubic inches. I'm guessing a typical 4 cylinder Lycoming sump has a footprint that is 12" x 12" or 144 square inches. The IO-540 sump in my garage has a cross section slightly larger - about 13.5" x 12" or 162 square inches. Where this is going is a quart of oil increases the oil level in the 4 cylinder's sump by 58 in^3/144 in^2 = 0.4 in. That means the additional quart of oil inside the sump touches a band 0.4" high x the 48" perimeter of the sump. Roughly 19 in^2. How much additional heat transfer is 19 in^2 of internal surface contact going to create? Not much, since the sump is already "at temp" due to the great heat conductive properties of aluminum. Also, the area on the outside of the sump exposed to cooling air won't change, and that cooling air that impinges the sump ain't exactly cool in the first place, because it has passed through the cylinder fins and around the exhaust headers. So, a quart of oil won't do anything meaningful. (Note, I used the word meaningful in my original post disputing the idea that oil quantity changes oil temperature.)

One of the tricks Lyc uses for oil cooling is to run the induction tubing through the oil sump. The incoming air draws a LOT of heat out of that oil, and letting it get low reduces not only the sump's contact area but the seriously cool tubing contact area.

Some of them have the whole bottom of the sump in contact with the induction plenum.

And that's just Lycoming. Continental doesn't do that except for the O-300. Their sumps don't handle induction air. Their smaller engines rely entirely on sump cooling. Low oil is hot oil.

1RTK1

Pattern Altitude

Thanks to BNT83 for posting the TCDS for the O-320.

The pertinent information, which he circled in red, is that Lycoming recommends you not take off with less than 6 quarts of oil in your O-320. On the other hand, Lycoming divulges that the engine will safely operate on two quarts. Why the difference?

It ain't cooling. It is oil consumption.

An extended range (52? gallon capacity) C-172 or a 160 horse Cherokee (50 gallons) has sufficient fuel to fly ~6 hours at ~65% power (roughly 7.5 GPH). Lycoming's 6 quart minimum for the O-320 prevents you from running low (or out) of oil before you run out of gas on your 6 hour flight. (Why anyone would want to spend 6 hours in a 172 is another issue entirely.)

Lycoming's published limit for maximum oil consumption is HP x .006 x 4 /7.4 = .52 Quarts/Hr for a 160 HP engine. So if you launch with 6 quarts of oil, consume oil at the maximum allowable rate (.52 QPH), and fly for 6 hours, you'll be down to just under 3 quarts of oil at the end of your flight, which is comfortably above the 2 quart "safe operating" minimum. This means your endurance is limited by fuel, rather than oil. That's what Lycoming wants and is how they determine the minimum "takeoff" oil quantity. Throw ferry tanks in the back and all bets are off!

To the idea that the sump rejects heat.

It does. No doubt. But does that rate change in a meaningful way with the addition of a quart of oil? I don't think so. A quart of oil is ~58 cubic inches. I'm guessing a typical 4 cylinder Lycoming sump has a footprint that is 12" x 12" or 144 square inches. The IO-540 sump in my garage has a cross section slightly larger - about 13.5" x 12" or 162 square inches. Where this is going is a quart of oil increases the oil level in the 4 cylinder's sump by 58 in^3/144 in^2 = 0.4 in. That means the additional quart of oil inside the sump touches a band 0.4" high x the 48" perimeter of the sump. Roughly 19 in^2. How much additional heat transfer is 19 in^2 of internal surface contact going to create? Not much, since the sump is already "at temp" due to the great heat conductive properties of aluminum. Also, the area on the outside of the sump exposed to cooling air won't change, and that cooling air that impinges the sump ain't exactly cool in the first place, because it has passed through the cylinder fins and around the exhaust headers. So, a quart of oil won't do anything meaningful. (Note, I used the word meaningful in my original post disputing the idea that oil quantity changes oil temperature.)

I do believe the capacity of the sump is a direct relationship to the max oil consumption recommend by the manufacturer. It’s bad form to run out of oil before you do fuel.

I would be willing to bet the oil temp would be cooler at 6 qts vs 2 qts under the same conditions

kyleb

Final Approach

- Joined

- Jun 13, 2008

- Messages

- 7,554

- Location

- Marietta, GA

- Display Name

Display name:

Drake the Outlaw

Have you ever had a Lycoming apart? Ever studied the parts manual or overhaul manual?

One of the tricks Lyc uses for oil cooling is to run the induction tubing through the oil sump. The incoming air draws a LOT of heat out of that oil, and letting it get low reduces not only the sump's contact area but the seriously cool tubing contact area.

I rebuilt the O-320 in my RV-6, so yes, I'm pretty familiar. ;-)

How much more cooling do you think you get from the induction side by adding a quart of oil, or ~0.4" of oil depth in the sump? Even with 5 quarts in the sump (and the 6th quart in the cooler, lines, filter, and galleries), how much of the induction piping would be submerged?

Got a sump sitting around to measure? You could calculate exactly how many quarts of oil it would take before the oil even touched the induction system. That would be interesting.

1RTK1

Pattern Altitude

What about the oil running over it.?

kyleb

Final Approach

- Joined

- Jun 13, 2008

- Messages

- 7,554

- Location

- Marietta, GA

- Display Name

Display name:

Drake the Outlaw

What about the oil running over it.?

You're talking about the oil that drains back to the sump from the crank, rods, etc and contacts the induction tubes on the way down? That amount is the same as long as you have at least 2 quarts of oil in the engine.

bnt83

Final Approach

I don't buy the Cessna POH saying 6 quart minimum when Lycoming says it must have at least 2 is for consumption. Look at the numbers with more critical thinking

That O-320 installed in a 172 is a small displacement 4 banger and Cessna says you need 6 quarts minimum.

That TSIO520 installed in a T210R is a lot more complex, six banger with a lot of displacement and Cessna says 7 quarts is the minimum.

The SR22T with a TSIO550 says oil capacity is 8 quarts, 6 minimum.

That O-320 installed in a 172 is a small displacement 4 banger and Cessna says you need 6 quarts minimum.

That TSIO520 installed in a T210R is a lot more complex, six banger with a lot of displacement and Cessna says 7 quarts is the minimum.

The SR22T with a TSIO550 says oil capacity is 8 quarts, 6 minimum.

bnt83

Final Approach

I stand by adding a quart or more on hot days making it run cooler. It's very noticeable on initial climb how much slower the temp rises

Stewartb

Final Approach

I don't know why Lycoming ran the intakes through the sump but we know that cold air induction makes more power. We also know that removing the tubes through the sump increases oil temps so we have to provide more cooling elsewhere.

Continental recommends a full 12qt sump for engine their big engine break in to improve cooling.

Random thoughts on a Thursday morning.

Continental recommends a full 12qt sump for engine their big engine break in to improve cooling.

Random thoughts on a Thursday morning.

AKBill

En-Route

Question. 0320-E3D never had carb icing. Is it because of induction system

Last edited:

Stewartb

Final Approach

Good question. Lots of guys believe so. Carb ice happens in the venturi, not the induction tubes.

Dan Thomas

Touchdown! Greaser!

- Joined

- Jun 16, 2008

- Messages

- 10,754

- Display Name

Display name:

Dan Thomas

First time I've ever heard that. The typical float-type carburetor runs the air through a venturi to increase its velocity and decrease its pressure so that it will suck the fuel through the nozzle and into the airstream. Unfortunately, decreasing pressure also decreases temperature by as much as 30°F. The fuel evaporating in the airflow can drop is another 70°F, since evaporation takes heat from the air to turn the liquid into a gas. The total drop is as much as 100°F, though such conditions would be rare. More typically total drop of 70°F or so is quite possible, which leads to the phenomenon of carb ice on hot but humid days.Question. 0320-E3D never had carb icing. Is it because of induction system

The Lycomings bolted their carbs to the bottom or back of that hot oil sump. The heat conducts through the metal and warms the carb body somewhat, making ice less likely compared to a Continental, but it's still possible and carbed Lycs still fail due to unrecognized or improperly handled carb icing. I don't see anything different about the E3D that would make it immune to ice.

The ice can happen in the venturi, on the throttle plate, and in the induction tubes. Lyc's tubes stay hot enough to prevent ice there, but if the engine is cold (oil not warm yet) you can get ice anywhere in there. We frequently had carb ice in the flight school Lycomings soon after startup on beautiful summer mornings. I'd hear the thing start, run for a minute and then start to die. I'd hear the engine rev a bit as the student (or instructor) opened the throttle to keep it going. I'd walk out and tell them to pull the carb heat; the engine would lose some revs, then pick up and run at much higher revs than it had been. An eye-opener.