Martin bevelander

Filing Flight Plan

- Joined

- Jun 14, 2018

- Messages

- 2

- Display Name

Display name:

C177a Sky Warrior

Cessna C177a FG 1969 model refers....

let me explain the issue please...this is not a shimmy problem.....

on landing, taxi & take off role there is no problem......when taking off there are no issues.....once rotated and climbing out the rotation speed on the front wheel reduces....then the crap starts.....its like a rrrrrrrr sound starting to settle in as the rotation speed reduces and then the rrrr sound disappears as the wheel further reduces rotation speed......it send a massive vibration through the firewall seriously vibrating into the firewall shaking the instument panel like crazy....

I replaced the front tyre and tube and since then its a problem....its sucha violent rrrrrr noize and vibration that I am too afraid to fly the plane....its really violent....

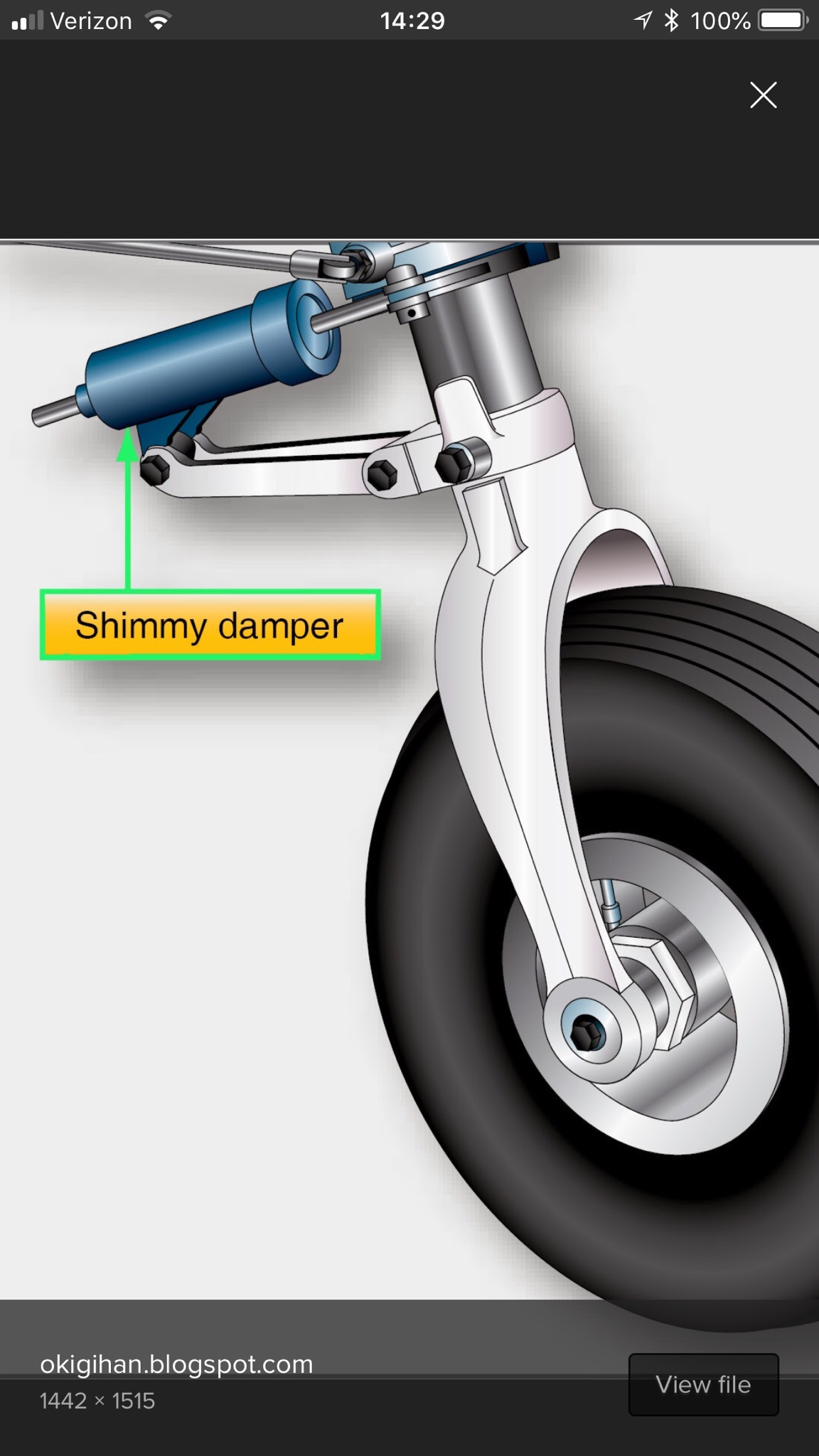

had the whole strut services....torque links shimming shimmy damper the lot ......ballanced the front wheel......its like a spanner or something was left inside the tyre......feels like a car with seriously our of ballance wheels.....massive rrrrr sound and high frequency vibration coming right into the firewall and instrument panel....

let me explain the issue please...this is not a shimmy problem.....

on landing, taxi & take off role there is no problem......when taking off there are no issues.....once rotated and climbing out the rotation speed on the front wheel reduces....then the crap starts.....its like a rrrrrrrr sound starting to settle in as the rotation speed reduces and then the rrrr sound disappears as the wheel further reduces rotation speed......it send a massive vibration through the firewall seriously vibrating into the firewall shaking the instument panel like crazy....

I replaced the front tyre and tube and since then its a problem....its sucha violent rrrrrr noize and vibration that I am too afraid to fly the plane....its really violent....

had the whole strut services....torque links shimming shimmy damper the lot ......ballanced the front wheel......its like a spanner or something was left inside the tyre......feels like a car with seriously our of ballance wheels.....massive rrrrr sound and high frequency vibration coming right into the firewall and instrument panel....