Timbeck2

Final Approach

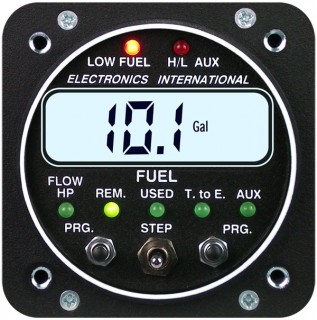

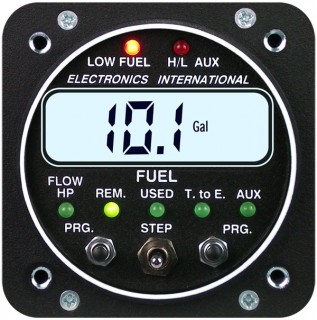

I've been thinking a lot lately about how I don't like the present system of fuel management in my Cherokee. I know how much fuel I have when I stick the tanks during pre-flight. I also know approximately how much I burn per hour at cruise. The fuel gauges are required to be accurate only some of the time as per the regulations. I'm going to install a Garmin G-5 to replace my wonky attitude indicator in addition to my turn and bank. In it's place I had originally planned to install an engine monitor that included fuel flow, EGT, oil pressure, temp, etc, but with the G5 at around $2100 and the engine monitor approaching $3,500 and the fact that all I really wanted to fuel flow, I've decided to go with this:

Someone talk me out of it, alternatives to it, or if you have it, tell me your experience.

Someone talk me out of it, alternatives to it, or if you have it, tell me your experience.