Capt. Geoffrey Thorpe

Touchdown! Greaser!

- Joined

- Jun 7, 2008

- Messages

- 15,632

- Location

- DXO124009

- Display Name

Display name:

Light and Sporty Guy

In the case where you add a ground rod and isolate the ground bus on the sub panel, do you still tie the ground wire from the main panel to the ground bus in the sub panel? Is there a potential for "potential" between the grounds with house wiring?

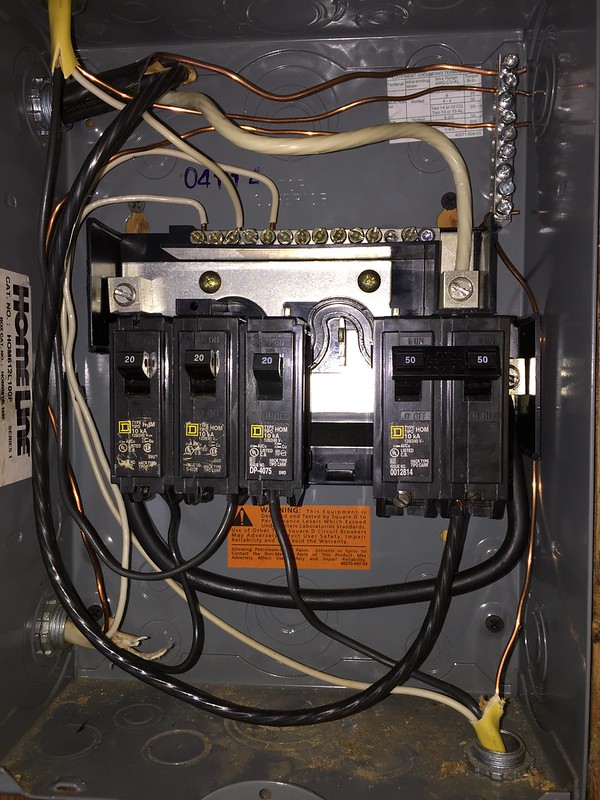

The ground in the garage is isolated from the "neutral" and is connected to a ground rod just outside the garage and the ground in the main panel.

There could be a small potential, but apparently it isn't a big issue.