Tom-D

Taxi to Parking

- Joined

- Feb 23, 2005

- Messages

- 34,740

- Display Name

Display name:

Tom-D

Yep, it's not rocket science.

It's not rocket science to CYA with proper documentation either.

Yep, it's not rocket science.

CYA is probably the crux of the entire problem as it seems it has become the prime directive whereas all we're talking about here are some machines we've created to fly through the air for our pleasure. How can we enjoy this wonderful creation if we can't so much as put air in the tires without someone worrying about their a$$.

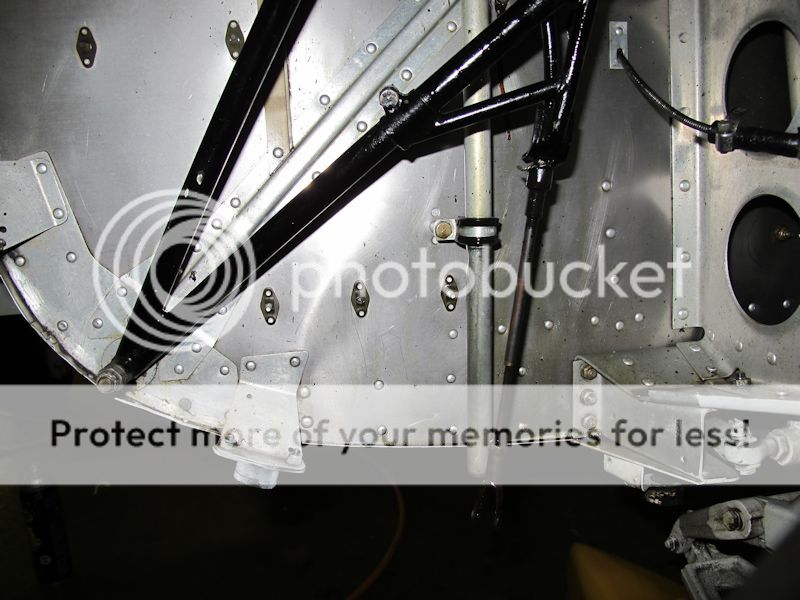

Holy moly there are a lot of holes in it. What are the odds those hole will match well? I sure hope it works out for you

I really appreciate threads like this one.

Every once and a while I get the crazy idea that I might like to own a Taylorcraft. Then I think about trying to maintain a type certificated airplane and threads like this make the desire go away.

Apparently Canadians don't mind fiery death raining from the sky.You Murricans need to press for an Owner-Maintenance category like we have here in Canada. Taylorcrafts are typical of the types that fit it. The owner can make parts legally, or substitute whatever works safely.

Dan

Apparently Canadians don't mind fiery death raining from the sky.

Up there chances are pretty slim you're gonna hit anything.

.......

.......We're currently working on that...IIRC the law has passed, just waiting for FAA implementation.You Murricans need to press for an Owner-Maintenance category like we have here in Canada. Taylorcrafts are typical of the types that fit it. The owner can make parts legally, or substitute whatever works safely.

Dan

...I still say that there are regulations out there that make keeping our aircraft SAFE too EXPENSIVE...

I haven't followed this entire saga here but loosely based on the pictures I saw I'd venture a guess that the real reason the entire firewall was replaced is because it was an insurance claim. Otherwise a perfectly good, legal and safe repair would have been accomplished and would have been finished about a year ago.

Is this what they pulled the firewall for?

I can see the one in pictures clear back to 2007 when you got the new engine in your blog...

I didn't know insurance covers pre-existing conditions. There is a 177RG driver here who got a free carrythru spar replacement when the corrosion was missed on pre-buy.

Anyone? Is this normal?

IIRC, her case was animal damage - a family of mice had taken up residence in the cabin overhead and their urine had started the corrosion.

Its bent right there by the tinnerman above the cowl mount.

Well, it's finally over. Nearly two years after the landing that did the damage, we're flying again.

The annual was signed off this week. I took her up for about 40 minutes yesterday afternoon. I did a few power settings and she made book speed, at least at 2,500 MSL. I also checked the autopilot and it works in both heading and nav mode.

She does need a bath, both inside and out, and I need to lubricate the seat mechanisms, but those will have to wait until I can bring her home. I'm going out of town for work for a week on Saturday, so I won't get a chance until later in the month.

Still it's good to have her back and in one piece!

Well, it's finally over. Nearly two years after the landing that did the damage, we're flying again.

The annual was signed off this week. I took her up for about 40 minutes yesterday afternoon. I did a few power settings and she made book speed, at least at 2,500 MSL. I also checked the autopilot and it works in both heading and nav mode.

She does need a bath, both inside and out, and I need to lubricate the seat mechanisms, but those will have to wait until I can bring her home. I'm going out of town for work for a week on Saturday, so I won't get a chance until later in the month.

Still it's good to have her back and in one piece!