Yellowbird

Pre-takeoff checklist

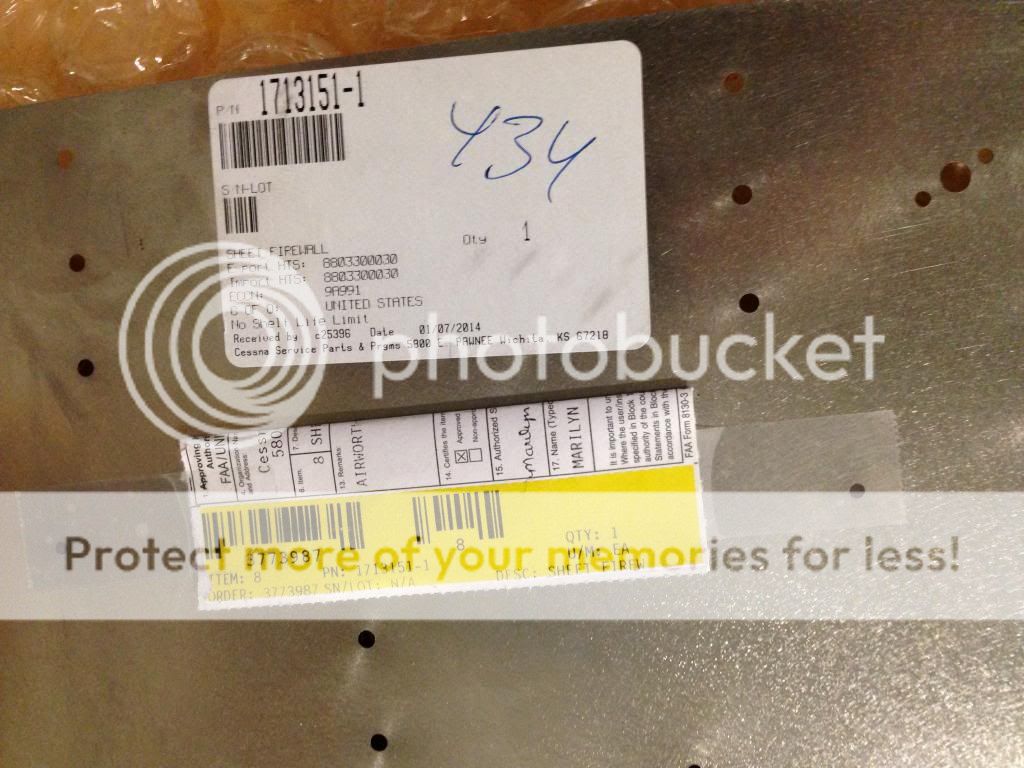

Look what Santa brought yesterday: (Almost a year since we ordered it)

Look what Santa brought yesterday: (Almost a year since we ordered it)

. What are the odds those hole will match well? I sure hope it works out for you

. What are the odds those hole will match well? I sure hope it works out for youWas it anywhere near the cessnaparts.com price of $1017?

Was it anywhere near the cessnaparts.com price of $1017?

Gotta love sheet metal @ 1017$ per square yard.... lol

I think after 3 months I would've cancelled the order and made one from scratch...

The problem is the legalities associated with making parts for certified airplanes. You can do it IF you have the technical specifications. But Cessna isn't going to give or sell the drawings for that thing so you'd be guessing at which stainless it might be.I would not have waited 3 months...

That thing would have been fabricated the next day...

The problem is the legalities associated with making parts for certified airplanes. You can do it IF you have the technical specifications. But Cessna isn't going to give or sell the drawings for that thing so you'd be guessing at which stainless it might be.

Long live homebuilts!

Dan

According to the Cessna Aircraft Company Single Engine Structural Repair manual:The problem is the legalities associated with making parts for certified airplanes. You can do it IF you have the technical specifications. But Cessna isn't going to give or sell the drawings for that thing so you'd be guessing at which stainless it might be.

Long live homebuilts!

Dan

The firewall is constructed of 0.016 inch, 18-8 corrosion resistant, annealed stainless steel sheet

I would not have waited 3 months...

That thing would have been fabricated the next day...

The bite comes from the fact that when you need one of those old, out of stock parts, someone has to set up tooling to make one. Short production runs cost big bucks and they pass the cost on.

About ten years ago I ordered a cabin heat box for a 152. Price back then was $1200.

Edit: If the dies for a stamped part are no longer available you got a problem, Houston.

And who would return a home made part to service ? dumber than chit with out all the blue prints and spec, that Cessna is not giving away.

........:wink2:.....

........:wink2:.....Cessna has hundreds of this type of parts in stock, I don't understand the year wait. These are not a stamped part. A simple sheet metal break will be the most you will need.

Order one and tell me how quick you get it.

The problem is the legalities associated with making parts for certified airplanes. You can do it IF you have the technical specifications. But Cessna isn't going to give or sell the drawings for that thing so you'd be guessing at which stainless it might be.

Long live homebuilts!

Dan

Nice try but that manual doesn't cover his airplane. I'd be willing to bet it's the same tho.

What aircraft does he have?

177B, unknown year

The Cessna Structural Repair Manual (SRM) does apply.

the one in the link may not apply, but there is one for the 177.

I saw that … see the previous post.Click the link. It doesn't apply

SINGLE ENGINE

MODELS 172, 182,

T182, 206 AND T206

1996 And On

There is no firewall data in the 177 structural repair section.

Cessna has hundreds of this type of parts in stock, I don't understand the year wait. These are not a stamped part. A simple sheet metal break will be the most you will need.

And who would return a home made part to service ? dumber than chit with out all the blue prints and spec, that Cessna is not giving away.

And who would return a home made part to service ? dumber than chit with out all the blue prints and spec, that Cessna is not giving away.

You best read what it requires to legally qualify a owner produced part for a production built aircraft.You're kidding, right? How do you think all the experimental planes are classified?

Sounds like you need to go take Mike Busch's maintenance seminar. He goes over owner produced parts quite extensively.

You can legally take the old firewall off. Hand it to a machine shop and say, "Make me one just like this." They use the damaged one as a template to fabricate the new one.

You hand it to your A&P and he installs it.

You best read what it requires to legally qualify a owner produced part for a production built aircraft.

The FAA can and with reason, cause you to prove it was built exactly the way the manufacturer built it.

You best read what it requires to legally qualify a owner produced part for a production built aircraft.

The FAA can and with reason, cause you to prove it was built exactly the way the manufacturer built it.

Do I need the manufacturer's blessing for an owner produced part?

Do I need the manufacturer's production drawing for owner produced part?

Does the owner have to physically build the part?

The AC says:

(1) The product must conform to its type certificate (TC). A product conforms to its TC when its configuration and the components installed are as described in the drawings, specifications, and other data that are part of the TC, which includes any Supplemental Type Certificates (STC), Airworthiness Directives (AD), and field approved alterations incorporated into the product.

end quote

to maintain production built aircraft as airworthy, it must be in it's proper altered condition, For that you must show that the components installed are as described in the drawings,specifications, and other data that are part of the TC, which includes any Supplemental Type Certificates (STC), Airworthiness Directives (AD), and field approved alterations incorporated into the product;

Show me how to prove that on owner produced parts with out some data on how the part was built.

Show me how to prove that on owner produced parts with out some data on how the part was built.

And how is that certified? and how do you gain approval by the FAA?As Henning already pointed out, we can subcontract the reverse engineering. If we have a lab tell what its made out of, for a flat sheet metal part that's about all you need. Rockwell hardness test and conductivity are popular and can be done at many MRO's.

You could easily remove the firewall and send it to a heavy sheet metal repair station for a duplicate, preferably without any holes in it. I'd want to transfer the holes myself.

Usually when a repair station does these kinds of owner produced or local produced parts that are consumed in a sheet metal repair, they will get two or more parts made, incase they mis-drill or somehow botch the first attempt at installation.

And how is that certified? and how do you gain approval by the FAA?