Ted

The pilot formerly known as Twin Engine Ted

- Joined

- Oct 9, 2007

- Messages

- 29,886

- Display Name

Display name:

iFlyNothing

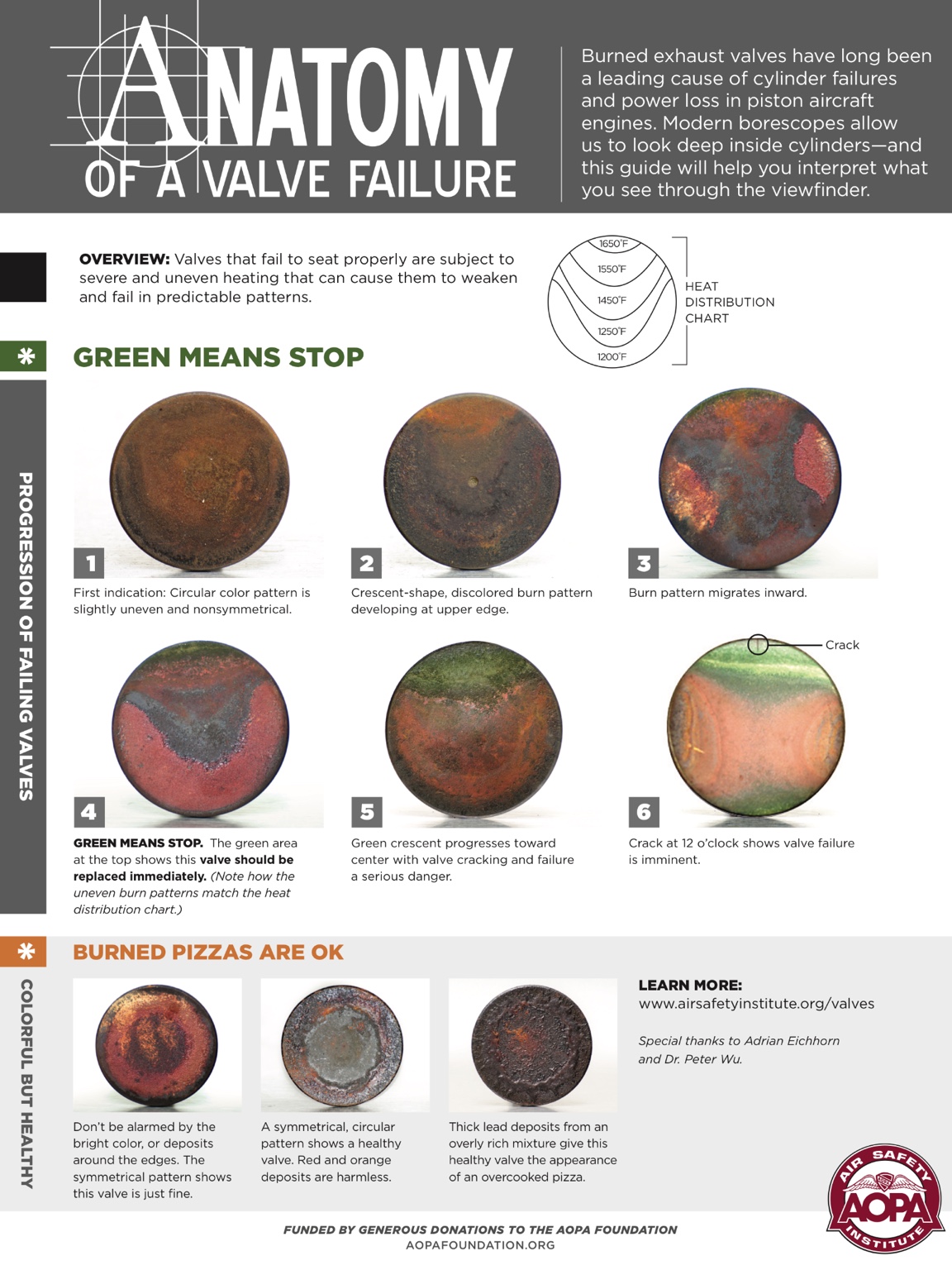

The #4 cylinder on the 414 burned its exhaust valve.

Indications were significantly higher EGT on the #4 cylinder on the engine monitor, coupled with the EGT varying some during normal cruise flight.

On the last leg of the flight on the hot start it seemed like one cylinder wasn't providing any resistance to the starter. Engine passed mag check and made power, though, so we decided to get home. It was cold and we were lightweight, so good performance.

Get it into the shop the next morning: 0/80 compression, with it all leaking past the valve.

Cause? Well it's a Continental that's got >1,000 hours on it.

Cylinder is off, new one is in shop, and getting put on. Will be done in time for my next rescue flight this weekend. Only 16 hours this time instead of 35.