Gone Flyin

Pre-takeoff checklist

- Joined

- Nov 30, 2020

- Messages

- 120

- Display Name

Display name:

Gone Flyin

Wondering if anyone has any data to that will help compare the Continental 0-200's RPM and cylinder compression to the horsepower it is producing.

In other words... this, from the internet:

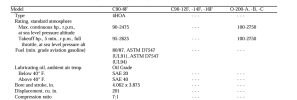

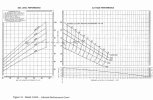

"The Continental 0-200 will give its maximum rated HP of 100, for a period not exceeding 5 minutes, at 2750RPM under correct atmospheric conditions".

I read the last part as a standard day at around sea level.

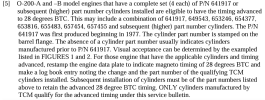

They do not say this... but, can one assume this is an engine producing a compression of (near) 80 over 80 for each of the four cylinders?

That being the case, is there a way to determine horsepower based on RPM? If an engine producing less than 80/80 on some cylinders is only producing an RPM of 2600 what is the approximate horsepower?

Let's forget about using a dyno to do this the right way. Just looking to get a rough idea, here.

In other words... this, from the internet:

"The Continental 0-200 will give its maximum rated HP of 100, for a period not exceeding 5 minutes, at 2750RPM under correct atmospheric conditions".

I read the last part as a standard day at around sea level.

They do not say this... but, can one assume this is an engine producing a compression of (near) 80 over 80 for each of the four cylinders?

That being the case, is there a way to determine horsepower based on RPM? If an engine producing less than 80/80 on some cylinders is only producing an RPM of 2600 what is the approximate horsepower?

Let's forget about using a dyno to do this the right way. Just looking to get a rough idea, here.