You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Ceramic coating

- Thread starter 4RNB

- Start date

- Joined

- Oct 16, 2019

- Messages

- 5,700

- Location

- Atlanta / KRYY

- Display Name

Display name:

Vintage Snazzy (so my adult children say)

I'm looking into options to clean up our club planes, and that is one of them.

Immaculate Airplane Cleaning quoted $2900 per plane (Skyhawk, Skylane) for a deep cleaning, polish/buff the paint, and apply Permagard ceramic. Takes about a day per plane. Lasts about a year (plane stored outside), and then $1800 if we want to have them clean it and re apply.

Have no experience with this, just started investigating. Any insights from those with real world experience would be appreciated.

Immaculate Airplane Cleaning quoted $2900 per plane (Skyhawk, Skylane) for a deep cleaning, polish/buff the paint, and apply Permagard ceramic. Takes about a day per plane. Lasts about a year (plane stored outside), and then $1800 if we want to have them clean it and re apply.

Have no experience with this, just started investigating. Any insights from those with real world experience would be appreciated.

I’ve done a number of cars, never an airplane. There are a lot of variables in material and time costs, depending on the outcome you’re seeking. Generally speaking, the cheaper DIY materials will work but the protective coating probably won’t last as long as the more expensive stuff. Prep work can take a long time too, depending on how perfect you want the paint to be before application. I wouldn’t worry about perfection on an airplane so a morning worth of prep work would probably be sufficient for most small airplanes.

One thing to remember - even a 172 size airplane has a lot more surface area to coat than a typical car or truck. Make sure you have an adequate amount of time and material to account for that.

One thing to remember - even a 172 size airplane has a lot more surface area to coat than a typical car or truck. Make sure you have an adequate amount of time and material to account for that.

- Joined

- Oct 16, 2019

- Messages

- 5,700

- Location

- Atlanta / KRYY

- Display Name

Display name:

Vintage Snazzy (so my adult children say)

Good tips Mondster, thanks. For our club, I think the only way to get it done properly would be to have the professional do it. Can you imagine the mess it would be if a club member burned through the paint while polishing? Or after all the work of prep it was applied poorly, or what we put on faded quickly? If the materials the company I'm looking at is good enough for corp jets, it will work on our 172s.

- Joined

- Aug 18, 2017

- Messages

- 2,421

- Display Name

Display name:

Hang 4

A basic GA airplane = 3 or 4 cars. I DIY'ed my Cherokee. It took me a week of 6 to 8 hour days. I had a lot of paint correction to do, which makes most of the appearance difference. The other thing to keep in mind is rivets. It's easy to polish the paint off of them if you are not paying attention. My paint was pretty crazed, so I had to wet sand (1000, 2500 grit steps), Rotary wool pad polish with some pretty abrasive polishing compound, panel wipe with rubbing alcohol then apply ceramic coating. Very fussy around rivet lines, seams and trailing edges.

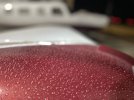

Here's the after picture

Here's the after picture

- Joined

- Oct 16, 2019

- Messages

- 5,700

- Location

- Atlanta / KRYY

- Display Name

Display name:

Vintage Snazzy (so my adult children say)

Very nice looking!

- Joined

- May 24, 2016

- Messages

- 914

- Display Name

Display name:

4RNB

When did you do this?A basic GA airplane = 3 or 4 cars. I DIY'ed my Cherokee. It took me a week of 6 to 8 hour days. I had a lot of paint correction to do, which makes most of the appearance difference. The other thing to keep in mind is rivets. It's easy to polish the paint off of them if you are not paying attention. My paint was pretty crazed, so I had to wet sand (1000, 2500 grit steps), Rotary wool pad polish with some pretty abrasive polishing compound, panel wipe with rubbing alcohol then apply ceramic coating. Very fussy around rivet lines, seams and trailing edges.

Here's the after picture View attachment 123451

Is the plane cleaner/faster/easier to clean?

Is it lasting?

- Joined

- Aug 18, 2017

- Messages

- 2,421

- Display Name

Display name:

Hang 4

About 2 years agoWhen did you do this?

Is the plane cleaner/faster/easier to clean?

Is it lasting?

Yes definitely

So far yes, I'd say it's a 3 yearish life. If I re-do it, it will be WAY less effort as there will be less paint correction. When I do it a again it will be Clay bar, polish, panel wipe and coat. Imron paint is very hard, so correction was a bit more effort for me. Other paints can be softer and therefore go more quickly.

- Joined

- Jul 21, 2014

- Messages

- 9,567

- Location

- Broken Arrow, OK

- Display Name

Display name:

SoonerAviator

The wife's Cadillac has ceramic coating done on it. It lasts longer than traditional wax jobs for sure, but I've heard most of the consumer-grade products don't last more than a year or so. The prep work makes the most difference in final appearance (just like with paintwork). Cutting/polishing/buffing the paint prior to ceramic application is where all of the real work is done. I'd guess a generic C172 has about as much surface area (or more) than my Excursion does, and that took me 3 days of pretty physical work to use an Random Orbital buffer and various compounds to prep for final coat. Granted I was working with an imperfect surface to begin with, but most aircraft paint isn't in great condition.

I'd probably pay to have that done on an aircraft.

I'd probably pay to have that done on an aircraft.

- Joined

- Aug 18, 2017

- Messages

- 2,421

- Display Name

Display name:

Hang 4

The actual coating does matter. This is what I used Ceramic Coating Not cheap, but very well reviewed. They make a professional grade that you need a commercial account to buy. "Ceramic" gets printed on a lot of stuff these days, not all of it is the real deal.

@SoonerAviator a plane is definitely at least 2x an Excursion if not more. I detailed my Expedition in a day and an Excursion is 1.5x that. You have no rivets on a car, nor trailing edges, nor little grooves in the ailerons and flaps nor seams. Also you never have to hold a buffer over your head underneath a wing. That's a real gym workout. Then you have the joy of being on crawler under the fuselage.

One really important step is to clean off all the oils from any polishing compound before coating. They sell something called panel wipe, which is basically isopropyl alcohol and water. If you don't, the coating won't stick or stay.

@SoonerAviator a plane is definitely at least 2x an Excursion if not more. I detailed my Expedition in a day and an Excursion is 1.5x that. You have no rivets on a car, nor trailing edges, nor little grooves in the ailerons and flaps nor seams. Also you never have to hold a buffer over your head underneath a wing. That's a real gym workout. Then you have the joy of being on crawler under the fuselage.

One really important step is to clean off all the oils from any polishing compound before coating. They sell something called panel wipe, which is basically isopropyl alcohol and water. If you don't, the coating won't stick or stay.

PaulS

Touchdown! Greaser!

Any p-static problems with these coatings?

- Joined

- Aug 18, 2017

- Messages

- 2,421

- Display Name

Display name:

Hang 4

Sample of one, no. I flew in the clouds before and after the coating and no problem. Lots of planes get it done, look on YouTube for Aviana Aircraft Detailing. He's done a ton of planes including Jets and Turboprops.Any p-static problems with these coatings?

My biggest issue is my gas caps tend to slide of the wing as it's darn slippery post coating. I left the labels alone and have to put the caps there.

its well worth it. The professional guys usually put a more professional product on it. You can DIY some good stuff as well, but steer clear of the local automotive stuff store. After ceramic coating - its just so much easier to clean the greasy under belly stuff. The oil/grease doesnt adhere as much and comes off much easier without using belly soap. As for applying it yourself - if the paint is in good shape - then generally I would say clay bar, and strip the wax/paint and go ahead. If you have to paint polish/color correct - it'll easily double the time. But it took me 3 days just to do wings.

- Joined

- Jul 21, 2014

- Messages

- 9,567

- Location

- Broken Arrow, OK

- Display Name

Display name:

SoonerAviator

I was mainly just talking in terms of surface area, not difficulty of the job itself with the rivets/grooved panels. Sort of like the same process on a boat. The boat hull isn't terribly difficult to do the polishing/wax (or ceramic coating), but your arms get tired of holding an electric buffer while laying on a creeper to get all of the bottom of the hull prepped. Great triceps and forearm workout though!The actual coating does matter. This is what I used Ceramic Coating Not cheap, but very well reviewed. They make a professional grade that you need a commercial account to buy. "Ceramic" gets printed on a lot of stuff these days, not all of it is the real deal.

@SoonerAviator a plane is definitely at least 2x an Excursion if not more. I detailed my Expedition in a day and an Excursion is 1.5x that. You have no rivets on a car, nor trailing edges, nor little grooves in the ailerons and flaps nor seams. Also you never have to hold a buffer over your head underneath a wing. That's a real gym workout. Then you have the joy of being on crawler under the fuselage.

One really important step is to clean off all the oils from any polishing compound before coating. They sell something called panel wipe, which is basically isopropyl alcohol and water. If you don't, the coating won't stick or stay.

For what it’s worth, how much preparation you do depends on what you’re starting with and what the intent for the coating is. Ceramic coating isn't magic, it is basically a paint preserver. So, if you want the brilliant shine that is often seen as being associated with ceramic coating, you're going to need to put in the hours to make it look like that before the coating ever goes on. If you're okay with the appearance of the aircraft after a good wash, you can just apply the coating as is.

tspear

En-Route

- Joined

- Dec 10, 2010

- Messages

- 3,552

- Display Name

Display name:

Timothy

This is the first I have heard of Ceramic coating.

Kinda curious, how much weight does this add to the plane? (Intellectual curiosity only).

Is it actually worth doing for a plane always in the hangar? I would think Ceramic Coasting is best for stuff left outside, especially exposed to UV (this is based on a 15 minute web search).

Tim

Kinda curious, how much weight does this add to the plane? (Intellectual curiosity only).

Is it actually worth doing for a plane always in the hangar? I would think Ceramic Coasting is best for stuff left outside, especially exposed to UV (this is based on a 15 minute web search).

Tim

It adds very little weight. A small plane like a Cessna 182/210 uses two small 5oz bottles for the entire plane. Think of it not as a coating, but as a much stronger and more durable wax. Would it be beneficial to tied down planes outside ? absolutely. But its also hygrophobic - which means that after flying - the greasy oil from the engine belly area just wipes out easily, rather than trying to belly soap it to get it off. It also works on windshields - so essentially its like having rainx on your windshield for 3 to 5 years.

- Joined

- Jul 21, 2014

- Messages

- 9,567

- Location

- Broken Arrow, OK

- Display Name

Display name:

SoonerAviator

It's no different than a coat of wax. I doubt the airplane scale is going to be accurate enough to measure it.This is the first I have heard of Ceramic coating.

Kinda curious, how much weight does this add to the plane? (Intellectual curiosity only).

Is it actually worth doing for a plane always in the hangar? I would think Ceramic Coasting is best for stuff left outside, especially exposed to UV (this is based on a 15 minute web search).

Tim

Ed Haywood

En-Route

It's no different than a coat of wax.

In several senses.

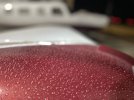

That’s beautiful! Can you split up the work and fly in between?Here's an after picture. Three years after coating.View attachment 123540

- Joined

- Aug 18, 2017

- Messages

- 2,421

- Display Name

Display name:

Hang 4

I wouldn't. The paint correction stages have no protection to the paint at all. I suppose you could fully do part of the plane, including coating, then fly it. But I think there would be a lack of efficiency in doing that.That’s beautiful! Can you split up the work and fly in between?

- Joined

- Aug 18, 2017

- Messages

- 2,421

- Display Name

Display name:

Hang 4

My plane is hangared and I consider it worth it. Bugs slide off, I can clean it all inside with a spray bottle and microfiber towels. People always ask me when I got it painted, the answer is 20+ years ago.Is it actually worth doing for a plane always in the hangar? I would think Ceramic Coasting is best for stuff left outside, especially exposed to UV (this is based on a 15 minute web search).

Tim

You would want a hangar for application even if it's tied down on a ramp. A lot of the products don't do well in direct sunlight during application.

I just can’t imagine starting on a project that big, I’m fine for a full days work but 5-6 full days, I’m worried about when it’s practical that I’d finish that up.I wouldn't. The paint correction stages have no protection to the paint at all. I suppose you could fully do part of the plane, including coating, then fly it. But I think there would be a lack of efficiency in doing that.

The last professional job i witnessed was on an arrow for 3500. A friend diy his archer over several days the ceramic product ran about 500 . Both planes stored outdoors seems to be holding up.

- Joined

- Jun 13, 2008

- Messages

- 7,685

- Location

- Marietta, GA

- Display Name

Display name:

Drake the Outlaw

You could do a wing. Then another wing. Then the fuselage. Then the tail. Or something like that.I wouldn't. The paint correction stages have no protection to the paint at all. I suppose you could fully do part of the plane, including coating, then fly it. But I think there would be a lack of efficiency in doing that.

But the time investment is a nightmare. Heck, I even struggle to find time to quickly wash the airplane every couple of months.

- Joined

- Aug 18, 2017

- Messages

- 2,421

- Display Name

Display name:

Hang 4

Hopefully posting this won't consign this thread to aviation media. This guy is the Zen Master of aircraft detailing and ceramic coating. He's doing a TBM in this video, but a lot of what he's doing applies to any plane. I find these almost hypnotic to watch and I have major tool envy. He really does a great job of explaining and showing the before and after.

Correct and Coat

Correct and Coat

- Joined

- May 24, 2016

- Messages

- 914

- Display Name

Display name:

4RNB

About the time I started this thread I submitted info to him requesting a bid from him, have not heard back. I've found someone closer to reach out to after the holidays.Hopefully posting this won't consign this thread to aviation media. This guy is the Zen Master of aircraft detailing and ceramic coating. He's doing a TBM in this video, but a lot of what he's doing applies to any plane. I find these almost hypnotic to watch and I have major tool envy. He really does a great job of explaining and showing the before and after.

Correct and Coat

The guy is absolutely excellent. Very very detailed oriented and does a top notch job. He will travel to you when he swings by somewhere near you and it takes him 3 days working 15 hours a day to do a 210 size plane. But he brings his tools and just polishes and coats every single little spot and rivet. A lot of the “car” guys are inexperienced with antennas, get frustrated with rivets and the nooks that a plane has. So he is an absolute top notch ceramic coating expert that has done cirrus, tbms to tail draggers.Hopefully posting this won't consign this thread to aviation media. This guy is the Zen Master of aircraft detailing and ceramic coating. He's doing a TBM in this video, but a lot of what he's doing applies to any plane. I find these almost hypnotic to watch and I have major tool envy. He really does a great job of explaining and showing the before and after.

Correct and Coat

I believe he is currently in Denmark doing some work. Didn’t know he traveled internationally but apparently he does

Randomskylane

Line Up and Wait

- Joined

- Jun 2, 2021

- Messages

- 663

- Display Name

Display name:

Randomskylane

I guess it’ll still look great after ten years since it’s usually in the hangar?Here's an after picture. Three years after coating.View attachment 123540

- Joined

- Aug 18, 2017

- Messages

- 2,421

- Display Name

Display name:

Hang 4

It gets flown pretty regularly and spends quite a bit of time outdoors in multi-day XC's. I'll likely re-do it this winter or next. It will be a lot easier this time as no wet sanding required. I suspect it will be a three day job this time. Wash with Dawn, Clay bar, polish/compound, panel wipe, coat. I kind of enjoy doing it, there's a real before/after difference that gives me a lot of satisfaction. Likely won't bother with wing undersides this time as they get no UV and no exhaust.I guess it’ll still look great after ten years since it’s usually in the hangar?

haha - the 2nd quote after the first will be so much better/easier because the prep to get it to ceramic coat worthy wont be there. Im not saying Im looking forward to doing it again - but it surely wont take as much elbow grease the 2nd time around. . . I prefer to use Simple Green (in various dilution amounts) over dawn. Dawn does strip the paint, but you have to be near water which my airport does not have.It gets flown pretty regularly and spends quite a bit of time outdoors in multi-day XC's. I'll likely re-do it this winter or next. It will be a lot easier this time as no wet sanding required. I suspect it will be a three day job this time. Wash with Dawn, Clay bar, polish/compound, panel wipe, coat. I kind of enjoy doing it, there's a real before/after difference that gives me a lot of satisfaction. Likely won't bother with wing undersides this time as they get no UV and no exhaust.

- Joined

- Jul 21, 2014

- Messages

- 9,567

- Location

- Broken Arrow, OK

- Display Name

Display name:

SoonerAviator

Dawn straps the grease/wax, not the paint. Bring a few gallons of distilled water from the grocery store.haha - the 2nd quote after the first will be so much better/easier because the prep to get it to ceramic coat worthy wont be there. Im not saying Im looking forward to doing it again - but it surely wont take as much elbow grease the 2nd time around. . . I prefer to use Simple Green (in various dilution amounts) over dawn. Dawn does strip the paint, but you have to be near water which my airport does not have.

Flyer Scott

Pre-Flight

- Joined

- Oct 31, 2022

- Messages

- 33

- Display Name

Display name:

Flyer Scott

I had it applied by https://www.planeshiny.com/services on my Saratoga. It wasn’t cheap but was well worth the investment. I am extremely “particular” and have a pretty good eye for paint defects. Bob is an absolute artist. He works magic on planes beyond what I would think is even possible.

The coating makes it very easy to remove bugs after each flight and the shine is impeccable. People routinely ask if the original paint on the plane was just painted.

The coating makes it very easy to remove bugs after each flight and the shine is impeccable. People routinely ask if the original paint on the plane was just painted.

David Loftus

Pre-takeoff checklist

ktup-flyer

En-Route

Yea, anything "ceramic" at your auto parts store is actually Si02. Gtechniq is a good brand... I'd probably do CSL topped with ExoV5The actual coating does matter. This is what I used Ceramic Coating Not cheap, but very well reviewed. They make a professional grade that you need a commercial account to buy. "Ceramic" gets printed on a lot of stuff these days, not all of it is the real deal.

@SoonerAviator a plane is definitely at least 2x an Excursion if not more. I detailed my Expedition in a day and an Excursion is 1.5x that. You have no rivets on a car, nor trailing edges, nor little grooves in the ailerons and flaps nor seams. Also you never have to hold a buffer over your head underneath a wing. That's a real gym workout. Then you have the joy of being on crawler under the fuselage.

One really important step is to clean off all the oils from any polishing compound before coating. They sell something called panel wipe, which is basically isopropyl alcohol and water. If you don't, the coating won't stick or stay.

Mooney Fan

Cleared for Takeoff

AeroColor used to own my 75 C-150 a few years back. They applied a ceramic coat to 25 year old paint. It looks really good and as others have said, makes for quick work removing bugs post flight.

PaulS

Touchdown! Greaser!

What is the going price for ceramic coating? I'm looking to have Mooney bravo done.

- Joined

- Oct 16, 2019

- Messages

- 5,700

- Location

- Atlanta / KRYY

- Display Name

Display name:

Vintage Snazzy (so my adult children say)

I found in the ATL area a place that will wash, polish the paint, and apply the ceramic coating to a Skyhawk for $2000.