But all it takes is a metal particle about 0.016" trapped between the outer race of a compound bearing/planet gear and the bearing rollers to cause a spall that leads to a fatigue failure

Same thing can happen if said particle gets caught in the critical internals of a Lycoming or Continental engine as well. So whats your point?

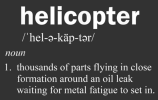

And there are more examples of things that would absolutely cause a bad day in a helicopter, while only causing an emergency diversion in the fixed wing world.

And the same can be said for fixed wing as well. You ever check the fatal rates on engine failures between fixed wing and rotor wing? Pretty much more airplane people have a worse day than helicopter people when the engine stops. And that’s just one example. As mentioned above if you compare the commercial helicopter accident rate… where the vast majority of helicopters operate… to the Part 91 non-commercial rate, you have a much better chance of bent metal in a private airplane than in a helicopter. So percentage wise you may want to 2nd guess the next time you sit in your buddy's Cessna.

FYI on your pics. That was the 2nd epicyclic failure with loss of MR assembly for that model/variant aircraft. The OEM blamed bad maintenance on both with their final determination the 225 transmission fell off a truck during transport some 1000 hours previous. The rest of the world found that in both accidents it was more the OEM had exceeded the transmission design limitations. The last I heard there were calls for the OEM to change the type design by clean-sheeting a new transmission that could handle the loads properly. So its a bit more than a single...

" metal particle about 0.016" trapped between the outer race ...."

No, I have no clue... please explain. While you're there, you can also talk to me about phase lag, why it's not 90 degrees, and how delta-3 plays into this.

Ha. Your posts sure seem to be big on questions and short on answers. But I’ll amuse you even on the specific rotorcraft items that you conveniently bring up.

In very general terms... in order for a helicopter to change directions in flight the “rotor disk” must be tilted toward the desired direction. What you are seeing in the video is the “cycle” of one blade out of four reducing pitch and increasing pitch to achieve the disk tilt as inputted from the cyclic stick.

In order for the rotor disk to tilt in the same relative direction as the pilot’s cyclic stick, that cyclic input must happen at a specific point in the rotor’s rotation. The reasons this phase lag can be less or more than 90 degrees depends on a number of factors: rotor design, rotor classification, flap hinge offsets, control speed, blade reaction speed, etc.

In short, when a pilot pushes the cyclic forward, that input is fed to the swashplate mounted on the main transmission via control tubes, mixing bellcranks, and servos. The sw/plate tilts at the prescribed point in the rotor rotation so that the retreating blade will increase to its max required pitch directly opposite of the “requested” direction thus tilting the rotor disk forward. The amount of degrees between the swashplate input and the blade reaching its full required pitch is called the phase lag. So in the video you'll notice the blades achieve full required pitch approximately as it crosses the tailboom which would "lift" the rotor disk and propel the helicopter forward.

If needed, Delta 3 angle will be added into the design equation to stabilize cyclic inputs, reduce external forces on the rotor, and so on by further offsetting the flapping hinge so that any flapping action of the rotor will modify the pitch of the blades. In other words, make it easier to fly. And as I recall, not much Delta 3 in the video design.

Now your turn to answer:

Why is the rotor system in your video more unique in terms of phase lag and Delta 3 than other rotor systems like on a R44 or AS350?

And while you're at it, we’re still waiting on your answer from the “minor alteration thread” on the reason(s) why you completely changed your mind on the topic after vehemently arguing it was not possible in your previous posts?

https://pilotsofamerica.com/communi...ied-avionics-be-so-crappy.146259/post-3493452