DaleB

Final Approach

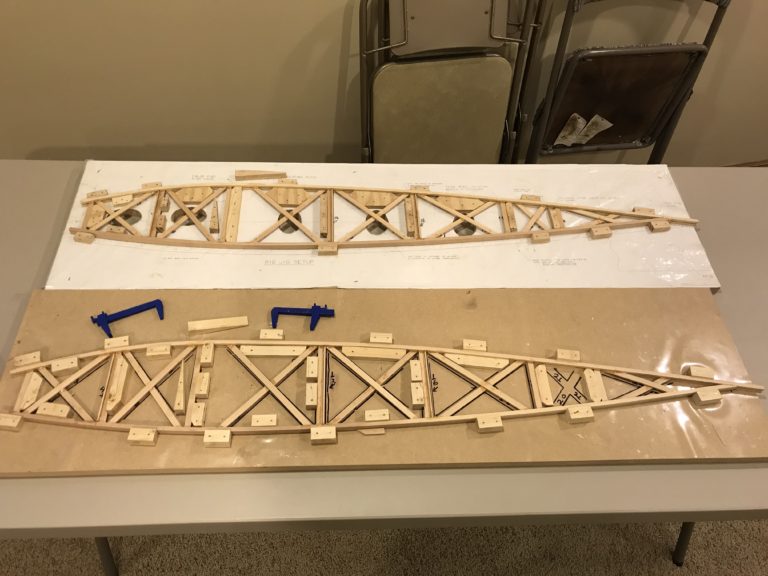

Having spent some time on an RV-7 project, I wasn't really enthused about building with aluminum again... but I missed having a project to work on. I don't weld, and I'm not sure I want to learn and practice welding until I get to the point where I would trust an aircraft fuselage that I welded. So... I'm working on an all-wood airplane now. There aren't a lot of them out there. Fisher products, Pietenpols and a few others. Anyone else here working on a flying wood project? It seems most of the dedicated builders of lightweight spruce creations are building boats.