Gone Flyin

Pre-takeoff checklist

- Joined

- Nov 30, 2020

- Messages

- 120

- Display Name

Display name:

Gone Flyin

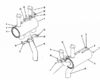

My A&P and AI are telling me the 0-200's exhaust on my C150 "is not air worthy because the inner baffle is worn through" and needs to be replaced, on both sides. They will not sign off the annual until this is corrected.

There are four bolts or nuts holding each of the two of them on. Frankly, I'm losing sleep on what can possibly happen when we try to remove these after all these years.

These guys tell me they have no insurance "cause it's too expensive" so should any of these get broken off I'm left with a grounded plane and a massive bill.

I'm looking for some advice on several fronts. Tips for removing the exhaust and who will be responsible for a bad outcome?

There are four bolts or nuts holding each of the two of them on. Frankly, I'm losing sleep on what can possibly happen when we try to remove these after all these years.

These guys tell me they have no insurance "cause it's too expensive" so should any of these get broken off I'm left with a grounded plane and a massive bill.

I'm looking for some advice on several fronts. Tips for removing the exhaust and who will be responsible for a bad outcome?