Our partnership put 316hrs on the plane last year and 200hrs the year before that. Last year, one of our members who’s a long-time A&P decided to get his IA back so we started doing 100-hr inspections to help him out as well as try to catch things in-between annuals with as much flying as we’re doing.

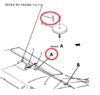

Started the inspection this morning and found this

Last 100-hr was in November and the flap cable was inspected and on the pulley. Glad to have caught it even though the plane is going to he down a while.

Started the inspection this morning and found this

Last 100-hr was in November and the flap cable was inspected and on the pulley. Glad to have caught it even though the plane is going to he down a while.