I still struggle though... (and I am easily confused.)

@Ted when I speak of crank offsets I mean mechanically, not necessarily what cylinders are firing at what time. So isn't it that the reduced crank offsets from odd cylinder configurations reduces vibrations by smoothing things out, or is it something else?

I'm not challenging. I'm asking. I want to learn here too.

So, if you're talking about the physical offsets of the rod journals on a crankshaft, there are vibration reasons why that can be desirable. However first to clear up, most 6 cylinders as I stated above have 120 degree crank offsets, not 60, which is still higher than the 90 degree offsets you see in a cross-plane V8 crankshaft (or a cross-plane I4 crankshaft, like the odd-firing Yamaha R1).

This really comes down to secondary vibrations. There are a lot of sources out there that explain secondary (and primary) vibrations better than I can, but probably the easiest way to think about this is that when a piston is moving from top dead center down the bore, it travels further during the first 90 degrees of crankshaft rotation than the second 90. This sounds weird at first but makes sense when you look at a piston/connecting rod/crank assembly from the front. For the first 90 degrees of crank rotation, the rod journal is moving down and out. For the bottom 90 degrees of rotation, it's moving the rod journal down and back in-line (straight up and down). This difference in piston distance traveled creates an inherent vibration.

Even-firing odd-number-cylinder engines have an inherent advantage her, so that's probably what you're thinking of. Secondary vibration forces especially come into play at higher RPM, which is why Yamaha went to a cross-plane I4 engine for the R1. That makes it an odd-firing engine, but a standard flat plane I4 has pretty bad secondary vibrations, and by making it a cross plane crank they reduced the secondary vibrations a great deal, which is part of how they got it to rev so high. My wife's Triumph Daytona was a 3 cylinder, revved to 14k RPM, and I think that was part of how they got it there as well.

You're seeing more odd-firing engines and interesting plays on firing order these days, like my wife's Triumph Tiger 900 - which has a 3-cylinder engine on a "T-plane" crank (think a cross plane V8 crank with one rod journal knocked off), which makes it odd firing but gives it a sound that blends a 3-cylinder and a V-twin. I don't think it has any balance advantages vs a traditional I3, but the point is manufacturers are doing it now, whereas the last odd-fire engine I can think of in the 1900s was an odd-fire V6 (GM I think?) from the 80s and it really wasn't very good or interesting. Like many things, tech has come a long way.

This sort of gets back to what

@Tarheelpilot requested of a more detailed response to some of the other posts made about vibrations. Engine vibrations are fantastically complex, and all reciprocating engines are going to experience vibrations and harmonics of some sort if you get them to the right RPM and the right conditions. Some of these are going to be due to the inherent layout of the engine regardless of power production as discussed above, and some are going to be from the power production itself.

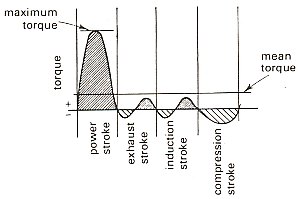

With few exceptions, piston engines will have the spark plug(s) fire on a cylinder at a particular point. That is the point of ignition, and from there cylinder pressure builds up and then starts to go down. This image shows it well:

In a multi-cylinder engine, the torque that the crankshaft receives is proportional to the cylinder pressure. This is essentially the above graph, but labeled differently to express this more clearly:

If you have a multi-cylinder engine, the torque that the crankshaft receives is essentially a lot of these same charts overlayed and offset for the firing of the different cylinders. See these xamples for a 4-cyl and 12-cyl:

When you get a torque number (like 500 ft-lbs), what that torque really is is the average. You have peak pulses for which the torque is much higher. Because of the mass of various parts (rotating assembly, flywheel, etc.) this smooths out the pulses. However ultimately this is also part of why you generally see spring clutches, it helps to absorb those pulses and smooth things out for the transmission. The specific size, peak, etc. of these torque pulses depends on many factors. Diesels have higher peaks that go up more rapidly. Low compression spark ignition engines with lots of cylinders have lower peaks that move up and down slowly.

But this is looking at torque at the flywheel. Remember that in any engine that's not a radial, you've got a crankshaft that has multiple rod journals, and so the torque pulses are being applied at different points within the crankshaft. And so you have what are called torsional vibrations, essentially how the crankshaft twist throughout a cycle if you measure a rotation between the front and rear of a crankshaft. On our aircraft engines, I recall that 1-1.5 degrees was about normal. On a car engine one of my colleagues once told me that seeing 3-5 degrees wasn't abnormal, especially during shifts (think about how quickly RPMs change, especially with some automatics or with someone who can't drive a manual very well).

And so this really gets back to the initial point of my responses about my brain hurting at the notion that a 6-cylinder engine was devoid of vibrations because it was constantly producing power. There is a LOT going on with respect to forces and resultant vibrations inside a piston engine of any number of cylinders through a cycle regardless of the number of cylinders, regardless of 2 or 4-stroke. Yes, as a rule more cylinders will equal smoother to the operator (there are exceptions). But the whole topic is exceedingly complex and I'll be the first to say that I'm not an expert on it, but I've spent enough time on it that I know a few things.

1) Engines vibrate. Period (turbines too)

2) There's stuff that goes on inside engines which may not seem inherently obvious, or even perceptible to the operator until you have things like metal fatigue, or an excitement of a natural frequency at a particular RPM that causes you to throw alternator belts due to your crankshaft counterweights getting detuned (seen that one before on an IO-520 - the video is impressive). This can also get into things coming from together if they get bad enough

3) When you see a yellow arc, there's usually a good reason why it was put there, and you should probably follow it