Stingray Don

En-Route

- Joined

- Dec 21, 2014

- Messages

- 2,964

- Location

- Indianapolis, Indiana

- Display Name

Display name:

Stingray Don

Okay, I just got the 172n back from annual and went for a trip around the pattern for a test flight today. Taxi and takeoff were normal as was the remainder of the flight until landing. Upon landing, the plane began to shake so violently that I was briefly unsure of my ability to even get it off the runway. Once I turned off the runway, the shaking stopped instantly. I have never experienced even the slightest shimmy in this plane. On the rare occasion when I have experienced a shimmy in other planes, it was just a minor annoyance and was easily corrected by changing the weight on the nose with the elevator. Today, the elevator had no affect on the shaking.

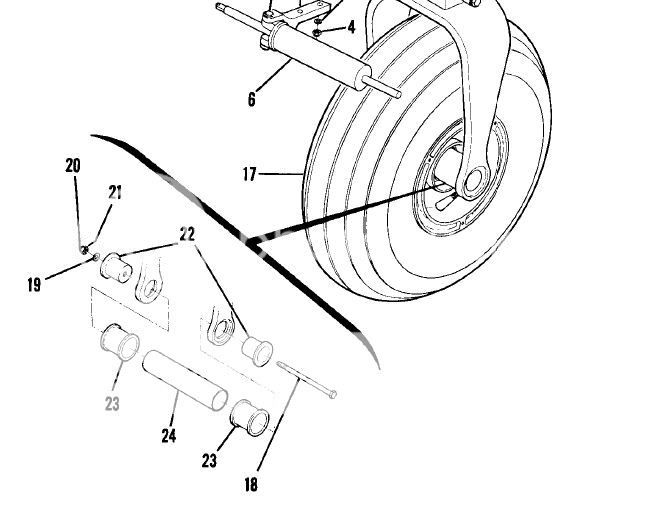

I'm assuming the shop did something wrong when they worked on the plane but I don't know. During the annual, the nose wheel fairing was replaced and the control cables were adjusted. I can't think of any other work which would have affected the aircraft during taxi. I'm not flying the plane again until the shop checks it out. Anyone have any thoughts on what could have caused such a violent shimmy?

I'm assuming the shop did something wrong when they worked on the plane but I don't know. During the annual, the nose wheel fairing was replaced and the control cables were adjusted. I can't think of any other work which would have affected the aircraft during taxi. I'm not flying the plane again until the shop checks it out. Anyone have any thoughts on what could have caused such a violent shimmy?