bnt83

Final Approach

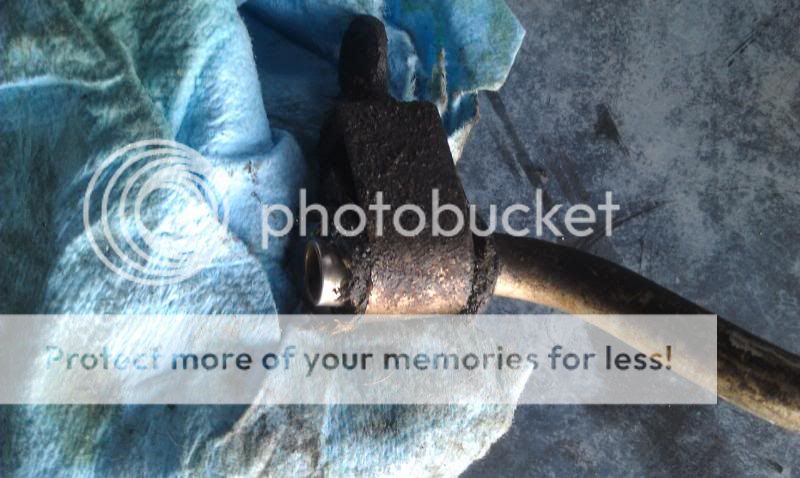

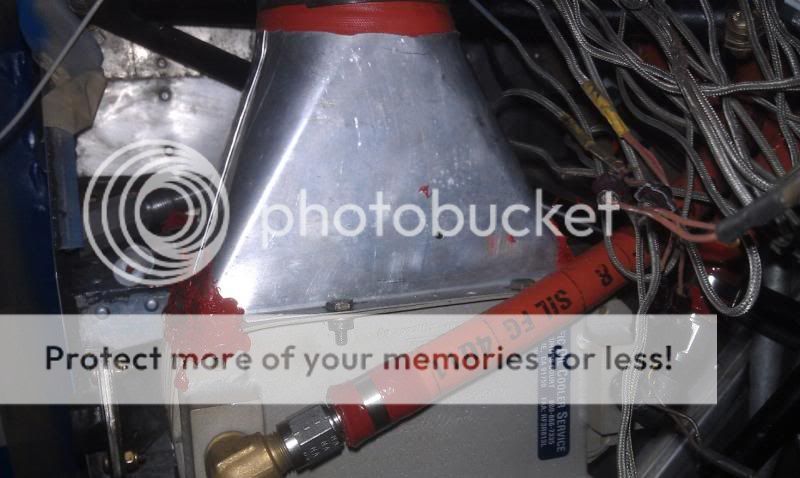

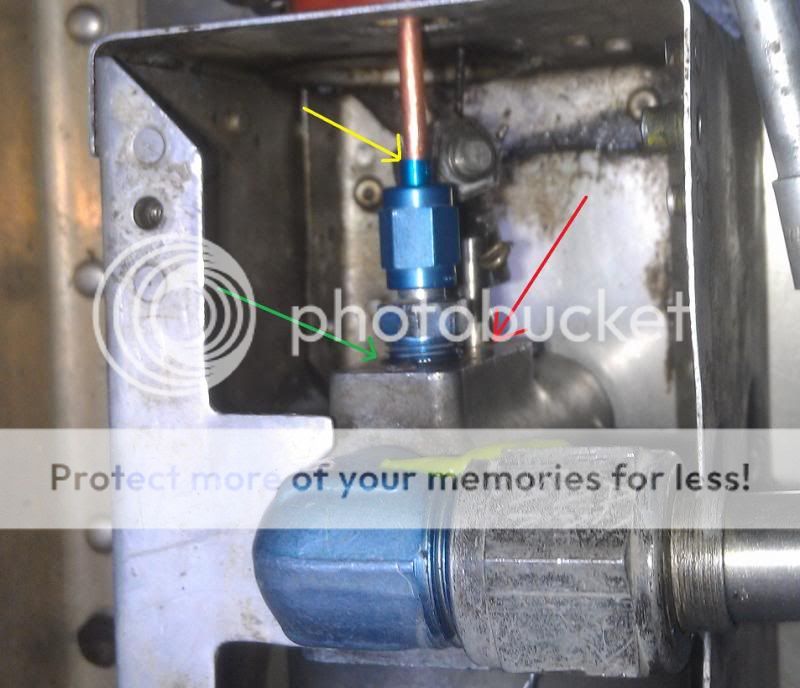

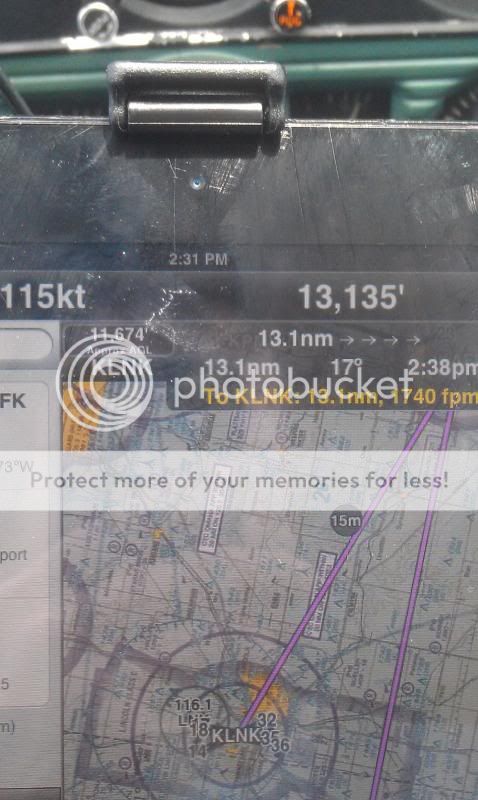

Getting much closer! I turned power on this weekend, purged the fuel lines while disconnected at the carburetor, operated the electric pump, hit the starter (all spark plugs removed) got oil pressure and mechanical fuel pump pressure. All the cabin air/heat ducting installed. Magnetos in their holes and timed.

Still waiting for rocker box drain back tubes... Still need to install new spark plugs, new ignition harnesses and a few other odds and ends.

Progress

I've done most of this myself but when it came to installing the mags, fuel pump and some other stuff, I had a good friend bail me out. He got more done in 8 hours than I possibly could! Standing on my stump feet to do the engine stuff is very difficult .

.

Still waiting for rocker box drain back tubes... Still need to install new spark plugs, new ignition harnesses and a few other odds and ends.

Progress

I've done most of this myself but when it came to installing the mags, fuel pump and some other stuff, I had a good friend bail me out. He got more done in 8 hours than I possibly could! Standing on my stump feet to do the engine stuff is very difficult

.

.

Last edited: