hindsight2020

Final Approach

- Joined

- Apr 3, 2010

- Messages

- 6,735

- Display Name

Display name:

hindsight2020

Lol the 'clear and present danger's rental scene. A classic, oldie but goodie.you can rent my plane for $125k, keep her as long as you need!

Lol the 'clear and present danger's rental scene. A classic, oldie but goodie.you can rent my plane for $125k, keep her as long as you need!

Come now. In THIS market? $275,000 and the engine only has 3000 hours on it!you can rent my plane for $125k, keep her as long as you need!

Ran when parkedCome now. In THIS market? $275,000 and the engine only has 3000 hours on it!

some shops offer ready to go engines that have been overhauled, you receive a zero timed engine immediately, and you have to pay based on the condition of the core you bring in. It’s more expensive than an overhaul of your own engine off course, but if you want the least possible downtime, that’s the way to go, unless you have a spare engine of your own to swap out.

Where did you get your cylinder from?One counter point. Had a cylinder fail compression test Friday. New cylinder will be at shop Monday or Tuesday. Lycoming O360.

Not sure the source, they use Zephyrhills for rebuilds who quoted 7-10 days depending on part availability. I'll post next time I stop by the shop.Where did you get your cylinder from?

Rings - quite a bit of time trying to reseat them. Last try compression was around 45. Could hear oil gurgling in the crankcase and I've had a bit more oil on the belly the last few months. I watched the last test, not flying that plane without replacing the cylinder, and I've listened to Busch, though even at 2.5X replay speed, he takes way too long to make his point.Did they do anything to see if they could get the compression up? Where was it leaking? Valves or rings?

Not sure the source, they use Zephyrhills for rebuilds who quoted 7-10 days depending on part availability. I'll post next time I stop by the shop.

Rings - quite a bit of time trying to reseat them. Last try compression was around 45. Could hear oil gurgling in the crankcase and I've had a bit more oil on the belly the last few months. I watched the last test, not flying that plane without replacing the cylinder, and I've listened to Busch, though even at 2.5X replay speed, he takes way too long to make his point.

I've listened to Busch, though even at 2.5X replay speed, he takes way too long to make his point.

Rings - quite a bit of time trying to reseat them. Last try compression was around 45. Could hear oil gurgling in the crankcase and I've had a bit more oil on the belly the last few months. I watched the last test, not flying that plane without replacing the cylinder, and I've listened to Busch, though even at 2.5X replay speed, he takes way too long to make his point.

No - but have had symptoms for 6 months. Thought is was a sticking exhaust valve early on. Morning sickness symptoms as EGT's were slow to come up. Replaced upper sparkplugs on the last oil change which improved the morning sickness, but still had more oil on belly than usual. If it was some carbon stuck on the rings, it would have been gone by now. Rest of compressions are fine. This cylinder is toast.Read his books.

Did they do a ring flush?

And 6 months at least of the piston slapping around in the cylinder. If it had just come up, I'd give it a whirl. I'm 99% sure the cylinder will be out of round.It sounds like you would the perfect candidate to try a ring flush. No, the carbon does not leave the rings. When the rings stick, the lack of ring tension means more oil is added which causes more buildup and more sticking.

Some shops? Only the factory (or AUTHORIZED shops, and AFAIK there are none) can Zero Time an engine?

0 Since Major Overhaul is NOT a 0 time engine. All the hours ever run on that engine continues in the log and continues to accumulate.

A Zero Time engine comes with a new logbook and a new serial number and truly starts again with 0 hours.

I agree^^^^^ doubt many shops can afford to have fresh engines in stock on the shelf?

Maybe if they specialize in one engine type?

2 years ago when I bought my engine from lycoming they had 3 options. Actually only 2 options for the motor I wanted.

New engines, some models with 0 time.

Overhauled engines with time on them.

And rebuilt like mine was with 0 time.

I think they used to call rebuilt "remanufactured"?

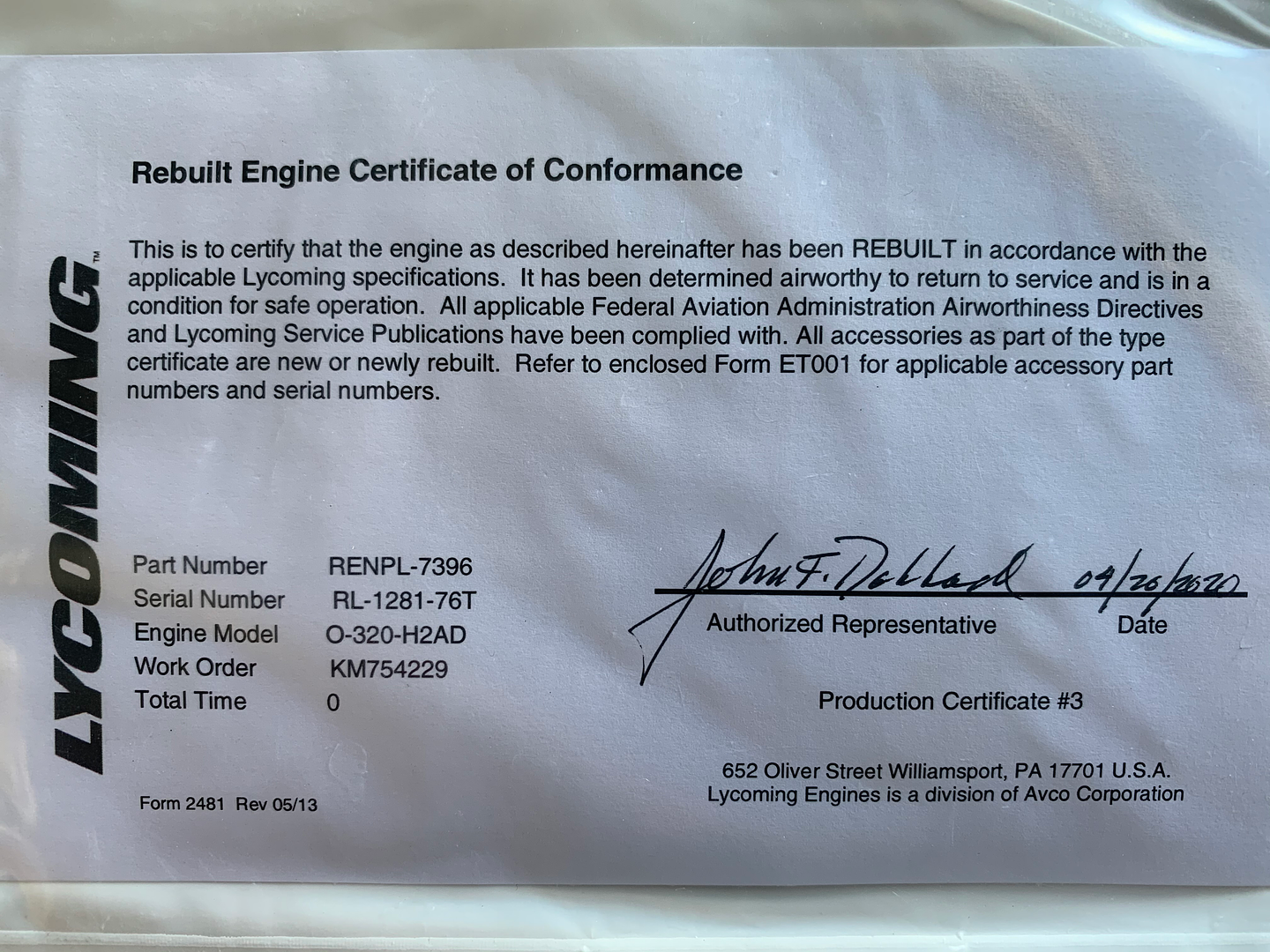

Here's what came with my rebuilt engine and a new log book.

Lycoming SL 250A says you have 120 days from the invoice date of the replacement engine before they need your core back.how far in advance can one buy a reman before you have to send back the core. with prices going up, if you thought you needed it in the next two years, you could put the crate in your dry garage with dessicant plugs and then do the swap in a couple of winters when your current one dies. It's also almost worth having a cylinder on hand (either new or O/H) to avoid a long downtime over a 2,000 part

Is the 36 years a EASA limit? I'm unfamilar of a similar limit for US engines and believe there are a few flying that well exceed 36 years of time.You can also get a factory overhauled engine these days, but that’s only an option if your engine is maximum 36 years old.

No, it’s a Lycoming limit, if your engine is over 36 years you have to get a rebuild, new or field overhaul. You cannot get a factory overhaul. It doesn’t mean you have a bad engine, just an old one.Is the 36 years a EASA limit? I'm unfamilar of a similar limit for US engines and believe there are a few flying that well exceed 36 years of time.

Do you have a reference? The Lycoming overhaul schedules I have access to at the moment dont reference any 36 year limit.No, it’s a Lycoming limit

Sure, check Service Letter 250A (https://www.lycoming.com/sites/default/files/Lycoming Engines Exchange Engine Core Policy.pdf)Do you have a reference? The Lycoming overhaul schedules I have access to at the moment dont reference any 36 year limit.

Okay. Its a engine core policy not part of an engine overhaul schedule. Minor detail but big difference on the other side. Learn something every day. Thanks.Sure, check Service Letter 250A

Yes. But there are other items that factor in as well. Lycoming has another bulletin that lists all the schedules: Service Instruction No. 1009BEwhat do you mean by schedule, something like the 12 year tbo?

I meant 0 SMOH, it’s a reset of the timer. You don’t need a true 0 timed engine anyway, otherwise there’s no point in overhauling your own engine? I really don’t get what you are trying to say here?

Just to close the loop on this sub-thread, looked at the removed cylinder today. Broken ring, and scored cylinder wall from the edge of the ring. Not even rebuildable. New Superior cylinder that was on the shelf at Zepherhills installed and waiting for VFR weather for a shakedown, break-in flight.No - but have had symptoms for 6 months. Thought is was a sticking exhaust valve early on. Morning sickness symptoms as EGT's were slow to come up. Replaced upper sparkplugs on the last oil change which improved the morning sickness, but still had more oil on belly than usual. If it was some carbon stuck on the rings, it would have been gone by now. Rest of compressions are fine. This cylinder is toast.

some shops offer ready to go engines that have been overhauled, you receive a zero timed engine immediately, and you have to pay based on the condition of the core you bring in. It’s more expensive than an overhaul of your own engine off course, but if you want the least possible downtime, that’s the way to go, unless you have a spare engine of your own to swap out.

Do you happen to know what the exact requirements are for an overhaul? Seems like everyone has an opinion rather than a link to a spec. The faa 43.2 an and b doesn’t spell everything out. Maybe it’s only done at AP school or something and I’m looking in the wrong places. TIAYou stated after an overhaul that it was a Zero time engine. It is NOT.

These are specific terms in the regulations. An overhaul has specific requirements to be an overhaul, otherwise it is an IRAN. Zero time has legal meaning.

If you ever sell a plane with an newly overhauled engine and advertise it is Zero time, get ready for some push back from buyers.

Yes, in most cases an overhaul is all you need. But even then, all overhauls are not the same. See the thread about Jewell Aviation that was just posted.

It does as bolded below. So unless you want to get a different set of standards and data FAA approved, the TC holder Overhaul Manual is the reference used when performing and signing off an overhaul per Part 43. And Part 43.13(a) provides further guidance to use the OEMs manuals. Some CRSs have gone beyond and had in-house overhaul procedures approved but outside that most shops and mechanics use the OEM manuals which details everything.The faa 43.2 an and b doesn’t spell everything out.