It's not as simple as question as it appears. Some self-locking fasteners that lock by virtue of an angular or pitch change in the ramp of the threads are indeed re-usable many times. Fasteners that lock by virtue of patches, adhesives or inserts aren't. Fasteners that lock by virtue of lock washers such as internal or external star may be re- used, but the locking washers are one-time use. Nordlock being the exception, but as was pointed out, those too have their drawbacks.

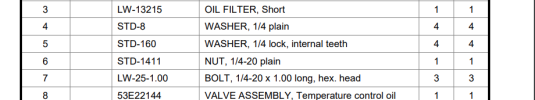

The problem I had with Lycomings IPC is that it called these fasteners self-locking, but come to find out they aren't, they lock by virtue of a captive washer. As expensive as they are, I assumed they would lock by the threads and actually fall into the reusable category. Turns out that was wrong by a long shot. I'm a bit OCD when it comes to nomenclature, I guess.

Pursued this more out of curiosity than anything else. Glad I did, I learned a bunch.

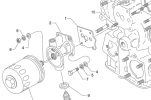

BTW, think I found that oil leak we were chasing

.

.