DesertNomad

Pattern Altitude

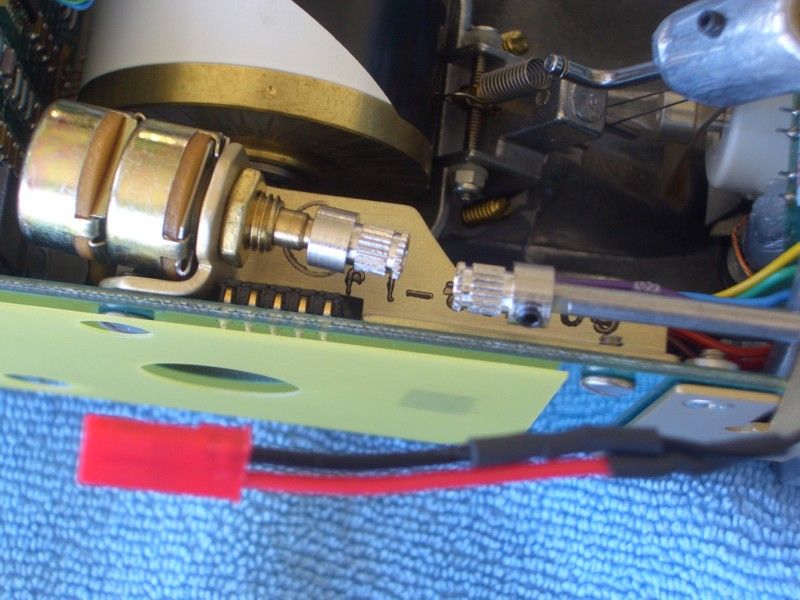

I have an S-TEC 30 that my shop moved one slot to the right to make room for a new engine monitor. In the process, the knob on the top left came loose and they did a temp fix to it by putting a small screw through the knob to friction-hold it to the shaft.

They said they will replace it but are calling other shops about the part rather than just calling S-TEC (Genesys) as my shop really does not do avionics (and is not an S-TEC dealer). Any idea what this will cost from Genesys? I think someone mentioned this sort of repair here before.

Another shop is going to install my new engine monitor (since I have all but given up on my local shop) and metal panel. I am thinking of getting the pert from S-TEC myself and just billing my original shop.

Really not happy that I can't find a good local shop in Reno. My favorite shop is 400 miles away near Portland, OR but the weather there and distance makes it very inconvenient.

They said they will replace it but are calling other shops about the part rather than just calling S-TEC (Genesys) as my shop really does not do avionics (and is not an S-TEC dealer). Any idea what this will cost from Genesys? I think someone mentioned this sort of repair here before.

Another shop is going to install my new engine monitor (since I have all but given up on my local shop) and metal panel. I am thinking of getting the pert from S-TEC myself and just billing my original shop.

Really not happy that I can't find a good local shop in Reno. My favorite shop is 400 miles away near Portland, OR but the weather there and distance makes it very inconvenient.