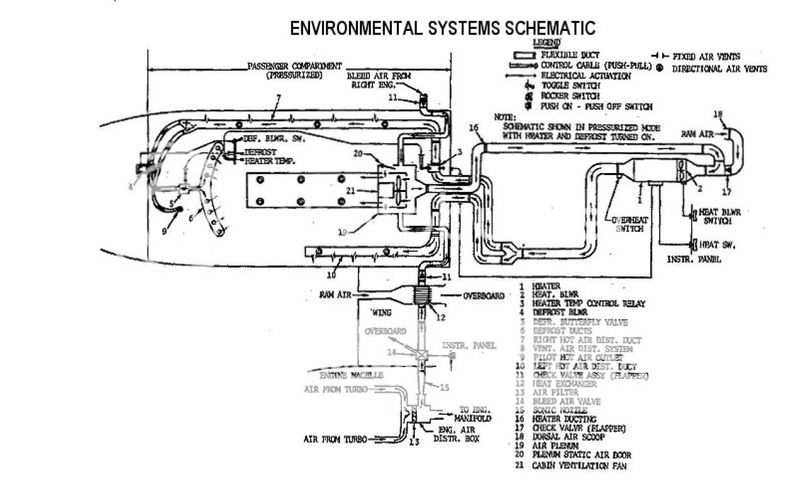

How are piston aircraft (like the Aerostar) pressurized? I get pressurization from turbine engines (bleed air, etc). Is there a separate engine driven accessory pump?

Thanks in advance, I didn't spend much time on the research for this one.

Thanks in advance, I didn't spend much time on the research for this one.