How much do you guys think Oleo Strut servicing might cost for a piper warrior? Inspecting my nose gear - found that the piston is depressed more than usual. its about 2.5 inches. Not sure as far as time is concerned - think about 1-2 hours of labor?

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

OLEO STRUT SERVICING

- Thread starter ZackJ

- Start date

MuseChaser

Pattern Altitude

- Joined

- Feb 23, 2019

- Messages

- 2,039

- Display Name

Display name:

MuseChaser

It's not an awful job. Depends what is wrong. As long as the strut tube itself isn't pitted, it's probably either a leak at the air valve at the top of the strut (which is a nothing job... definitely check this first) or an o-ring/seal kit which isn't bad either, although I don't think you can get to the top seal w/out removing the whole strut assembly. All of the other rings and seals can be addressed just by dropping the fork tube. My experience is w/ a '65 Cherokee. Took me four hours w/ an A/P laughing at me. I doubt it would take an A/P longer than two hours. Check the air valve first.

Last edited:

Unit74

Final Approach

- Joined

- Mar 8, 2014

- Messages

- 6,992

- Display Name

Display name:

Unit74

MuseChaser

Pattern Altitude

- Joined

- Feb 23, 2019

- Messages

- 2,039

- Display Name

Display name:

MuseChaser

Those are good articles. Just to clarify.. you can "service" the struts yourself, meaning replace the fluid and air/nitrogen. You can not do the seals.

Tom-D

Taxi to Parking

- Joined

- Feb 23, 2005

- Messages

- 34,740

- Display Name

Display name:

Tom-D

I've done it on a Cherokee 6. All you need is a good jack, a suction pump and a source of high pressure Nitrogen or air....

Tom-D

Taxi to Parking

- Joined

- Feb 23, 2005

- Messages

- 34,740

- Display Name

Display name:

Tom-D

Any idea what a tank, regulator, high pressure hose cost ?I've done it on a Cherokee 6. All you need is a good jack, a suction pump and a source of high pressure Nitrogen or air....

Rgbeard

En-Route

- Joined

- Aug 26, 2017

- Messages

- 4,253

- Location

- Phoenix, AZ and Ensenada, Mexico

- Display Name

Display name:

rgbeard

Not having done any strut maint myself yet, but I've used this on motorcycles.

Is the technology the same?

https://www.motosport.com/motion-pro-sealmate?variant[MOP002Q]=MOP002Q-X001-Y001

Is the technology the same?

https://www.motosport.com/motion-pro-sealmate?variant[MOP002Q]=MOP002Q-X001-Y001

Any idea what a tank, regulator, high pressure hose cost ?

Nope. Borrowed it.

hindsight2020

Final Approach

- Joined

- Apr 3, 2010

- Messages

- 6,723

- Display Name

Display name:

hindsight2020

Nope. Borrowed it.

Yup. The only way to survive this blasted hobby. That or going EAB and doing whatever the hell you want (within reason)

I'm inching towards the latter. Can't leave the kid at home yet, so for now the backseat forces me to certified hell.

deyoung

Line Up and Wait

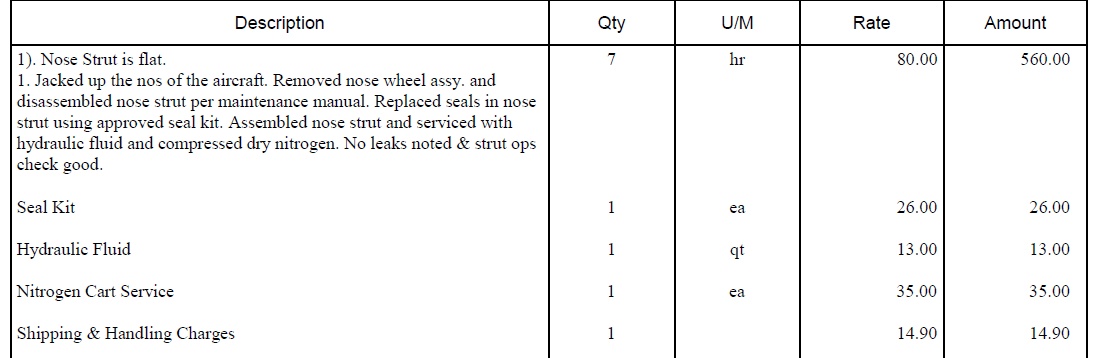

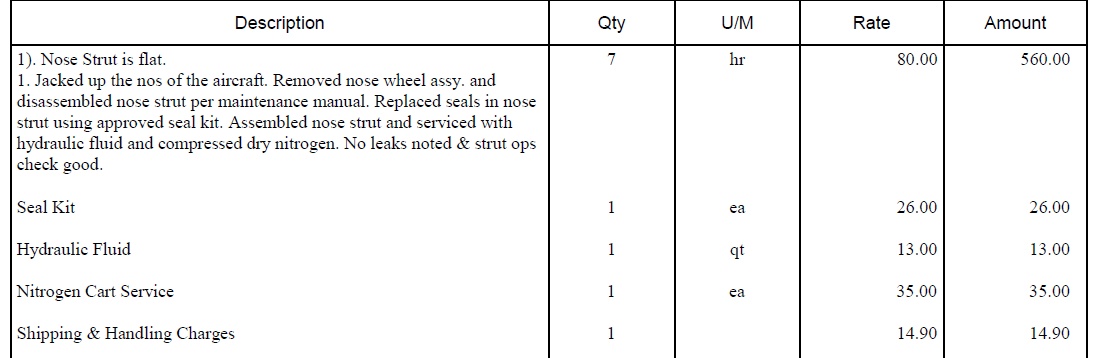

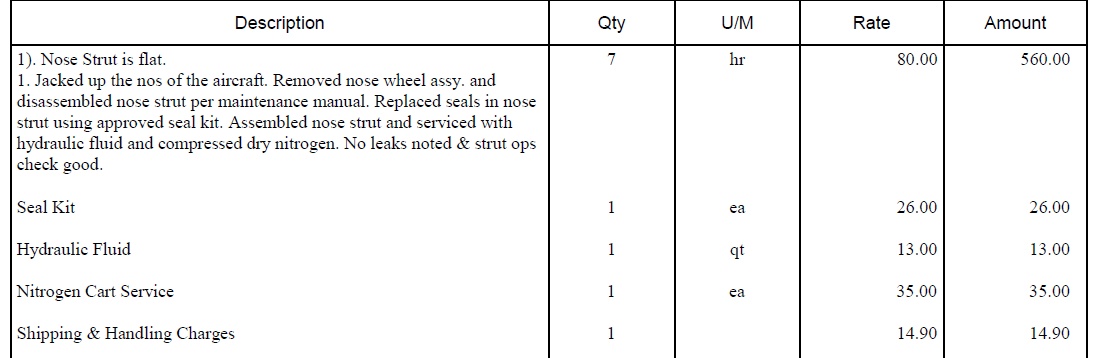

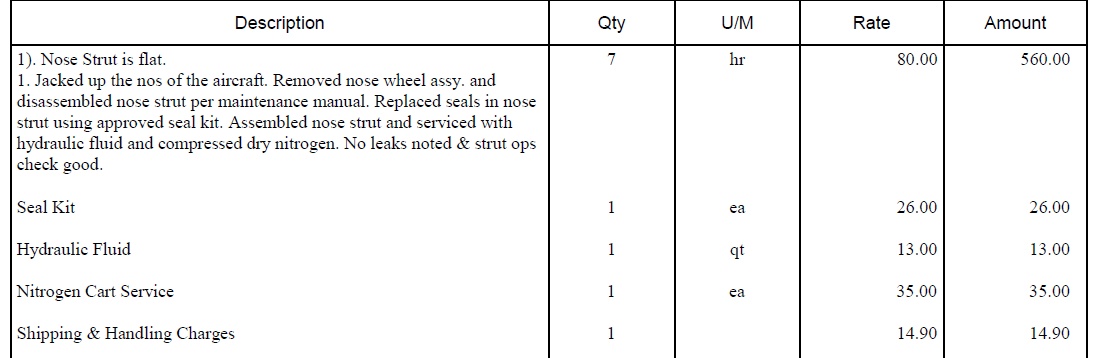

Funny you should ask... just ran into this in the last couple weeks.

Prices in Tucson AZ; your local mileage may vary. PA-28-235 but I doubt it's any different for yours.

Prices in Tucson AZ; your local mileage may vary. PA-28-235 but I doubt it's any different for yours.

deyoung

Line Up and Wait

To add, ruled out the top valve before doing this. Definitely check that first; if it's the problem, it's much easier and cheaper.

Also, when you say low, how low is low? 2.5 inches lower than it was yesterday, or 2.5 inches showing (which is enough to be still okay if it's not changing rapidly)?

Also, when you say low, how low is low? 2.5 inches lower than it was yesterday, or 2.5 inches showing (which is enough to be still okay if it's not changing rapidly)?

Unit74

Final Approach

- Joined

- Mar 8, 2014

- Messages

- 6,992

- Display Name

Display name:

Unit74

Funny you should ask... just ran into this in the last couple weeks.

Prices in Tucson AZ; your local mileage may vary. PA-28-235 but I doubt it's any different for yours.

7 hours? Makes that $80/hr rate seem like a moot point.

It’s a fairly new aircraft for me - but my neighboring warrior II has about 3 inches + of clearance. What got me started was a shimmy I experienced during landing. I’m aware that this could also be a due to the linkages.

NordicDave

En-Route

Concerning nose struts... My own experience once one component of the nose gear to shot, the other parts follow pretty quickly. Rebuilding the Oleo strut, new fluid, nitrogen, toggle link rebuild, and shimmy damper rebuilt was an 9 hour job. My MX and I did it on my hangar.

Also make sure the nose wheel is balanced. Check the the shimmy dampener to fuselage mount and needle bearings in main collar. These age and get sloppy too.

-David

Also make sure the nose wheel is balanced. Check the the shimmy dampener to fuselage mount and needle bearings in main collar. These age and get sloppy too.

-David

Last edited:

unsafervguy

En-Route

seven hours? did that include a long lunch?Funny you should ask... just ran into this in the last couple weeks.

Prices in Tucson AZ; your local mileage may vary. PA-28-235 but I doubt it's any different for yours.

deyoung

Line Up and Wait

seven hours? did that include a long lunch?

Ok, so, one person said their similar job was 8 hours, and two people have said (essentially) 7 hours, WTF???

So -- I'm not going to do the work myself; I don't have the skills, the time, a good place to work, etc., etc. I have a full time job and if I want to look over my A&P's shoulder for the whole job I'll pay for the time to do that too.

So what do you all suggest? I can ask him to justify everything that seems excessive to me (based on, well nothing at all since what do I know about what it really involves)? Or... what?

He knows the airplane and, as far as I can tell, seems to do good work. Beyond that, really what do you think I should be doing differently?

(And yes - although no one has come out and quite said "man you're getting ripped off" I'm definitely getting that vibe, which is what I'm reacting to.)

hindsight2020

Final Approach

- Joined

- Apr 3, 2010

- Messages

- 6,723

- Display Name

Display name:

hindsight2020

count me out of that group @deyoung . i dont think 7 hours its outrageous for a re seal plus r/r, especially at 80/hr. at first i thought it was just servicing the strut, at which point yes i was gonna agree with the mob. but for a reseal where the strut was removed, yeah 7 is ok to me at 80/hr. im a turn key pilot, im not retired so i defer to the AP for his time. that doesnt mean i blindly go get bent, after all i choose a slow simple airplane when i can afford a bigger one, precisely to control my variable mx wild cards. but i certainly have no issue paying a slight premium for the APs time and my convenience. when im retired ill go wrench on my EAB. For now time with family is more pressing.

Last edited:

Timbeck2

Final Approach

Ok, so, one person said their similar job was 8 hours, and two people have said (essentially) 7 hours, WTF???

So -- I'm not going to do the work myself; I don't have the skills, the time, a good place to work, etc., etc. I have a full time job and if I want to look over my A&P's shoulder for the whole job I'll pay for the time to do that too.

So what do you all suggest? I can ask him to justify everything that seems excessive to me (based on, well nothing at all since what do I know about what it really involves)? Or... what?

He knows the airplane and, as far as I can tell, seems to do good work. Beyond that, really what do you think I should be doing differently?

(And yes - although no one has come out and quite said "man you're getting ripped off" I'm definitely getting that vibe, which is what I'm reacting to.)

Chris, I'm wondering where this invoice was from. 7 hours to remove, rebuild, and replace a nose strut doesn't sound all that far fetched considering what I've seen on other airplanes and the disassembly/reassembly and the cleaning and inspecting that goes on. Looks as if they have a pretty hefty mark up in price for the seal kit as that can be bought for $16. A quart of Mil 5606 is $7, and the "shipping and handling" charge is probably double what it is too. It takes a few dollars for nitrogen but IMO $35 is a rip off. I realize that most shops want to make a profit and up-charging for parts is common but it would seem to me that you got charged 100% markup on everything except the labor.

deyoung

Line Up and Wait

Chris, I'm wondering where this invoice was from.

Aero Experts (Ki Yoon, Johhny Hale, et al) working out of the Jet Center. I actually tend to split my maintenance between them and Tucson Aeroservice in Marana.

I'm completely sure that I'm getting charged more than cost and more than I would pay if I did more of it myself, but since I still work full time a lot of maintenance would get procrastinated a lot if it waited for me...

NordicDave

En-Route

Aero Experts (Ki Yoon, Johhny Hale, et al) working out of the Jet Center. I actually tend to split my maintenance between them and Tucson Aeroservice in Marana.

I'm completely sure that I'm getting charged more than cost and more than I would pay if I did more of it myself, but since I still work full time a lot of maintenance would get procrastinated a lot if it waited for me...

You didn't get ripped off. 7 hours is quite reasonable to rebuild an Oleo strut. Parts slightly expensive, and agree that nitrogen for $35 is nuts. It's $21 dollars to fill a 30 cu' bottle. Maybe they had to rent it from another shop?

deyoung

Line Up and Wait

Maybe they had to rent it from another shop?

I doubt it - I'll bet this one really is just crazy markup, mostly because they are usually working on King Air's and up, and for those guys a $35 line item gets ignored in an $11,000 invoice...

hindsight2020

Final Approach

- Joined

- Apr 3, 2010

- Messages

- 6,723

- Display Name

Display name:

hindsight2020

I doubt it - I'll bet this one really is just crazy markup, mostly because they are usually working on King Air's and up, and for those guys a $35 line item gets ignored in an $11,000 invoice...

Oh absolutely, I saw that line charge and saw the same typical dynamic you highlight. Not condoning it but like you, I have seen worse in my own experience. The one time I have been legitimately ripped off in this hobby was by Atlantic at KOKC, which invoiced me $170 dollars ex post facto for a verbal request to "put some air on the left tire", which devolved into a call-out charge in absentia, and the testimony of their own line guy that he saw the guy they called out (uncontracted third party from the FBO across the field) approach my airplane, check the tire pressure, and end up not adding any air at all and leaving! The FBOs decision to not rectify the situation led to my permanent departure from their patronage, which I'm sure they don't miss as a turbine-centric operation.

For all my complaints about certified aviation, I've largely had a relatively positive relationship with my APs and *avionics vendors (*mostly limited to 91.411/413 checks) I've patronized. My former AP was a bit heavy on the labor rates, but that's because he could in a remote location. I never had complaints with the quality of the work though.

I do stay away from prop shops (I make them come to my airplane and hangar for the eddy current LOL), big box FBOs for mx, and name-recognition boutique engine shops, so that skews my experiences wrt rent-seeking interactions. I do look forward to EAB though, and I will still patronize AP for the major jobs (and condition inspections of course, no IA needed for that, though most of my APs have also been IAs).

Kenny Phillips

Final Approach

- Joined

- Jul 29, 2018

- Messages

- 5,493

- Display Name

Display name:

Kenny Phillips

Gee, if I recall correctly, servicing two motorcycle fork legs, including R&R, new seals and fluid, and air pressure, was about 1.4 hours. And it didn't take that long. Certainly, on a Skyhawk, I could do it rather quickly. Perhaps there's something about that particular plane that kills most of a day.

Glenn D

Pre-takeoff checklist

I put together a Nitrogen setup for less than $150.. Small bottle, regulator hose and fitting... great to do my own when needed....

Any idea what a tank, regulator, high pressure hose cost ?

Last edited:

hindsight2020

Final Approach

- Joined

- Apr 3, 2010

- Messages

- 6,723

- Display Name

Display name:

hindsight2020

Gee, if I recall correctly, servicing two motorcycle fork legs, including R&R, new seals and fluid, and air pressure, was about 1.4 hours. And it didn't take that long. Certainly, on a Skyhawk, I could do it rather quickly. Perhaps there's something about that particular plane that kills most of a day.

You probably know there isn't anything special about PA-28 variants struts, so I take your question as rhetorical. If not, then yes, PA28 struts are not special.

It's just a time value trade. The "hourly" figure is a canard. Call it potato units. Everything is fungible. For you that total outlay isn't worth it, for others with different starting points on that continuum (availability of tools, time off, mechanical inclination, outright desire to do the work) the figure would seem worth it. When I had no money and a lot of time, tinkering with my POS jeep cherokee (easy to access) was worth it. Nowadays I need dispatch and make more money, so I have two new korean/japanese cars respectively where you have to take the whole thing apart to access anything, making the tinkering impractical. But I make more money and my time is more valuable on other pursuits. When I retire/the kid goes off to college Im sure that will change again. Nothing new under the sun.

Tom-D

Taxi to Parking

- Joined

- Feb 23, 2005

- Messages

- 34,740

- Display Name

Display name:

Tom-D

servicing is usually $20, If you must service that often to rationalize that cost you should repair the strut.I put together a Nitrogen setup for less than $150.. Small bottle, regulator hose and fitting... great to do my one when needed....

Sinistar

En-Route

- Joined

- Sep 9, 2016

- Messages

- 3,712

- Display Name

Display name:

Brad

Man 7hrs of labor seems high. Maybe its a low wing thing?

I flew the 182 down to our mechanic to have the front strut on the 182 serviced as it was leaking air (but not fluid) during the negative temperature days this winter. Normally I would just drop it off but he said "You can hang around it won't take long". We put 4 cases of oil on the tail and it was up in the air ready for work. Over the course of about 15 minutes he kept pulling out more rings and finally had it out and poured out the fluid. 10 minutes later he had new orings and started putting it together. He just pushed the wheel up and had it draw fluid in from a bottle (I forget the order). All in he charged me 1.25hrs labor and some simple parts.

Part of that 1.25 was testing my Cessna jumper cable because while chatting I mentioned the side plug on the plane hadn't worked for the avionics guy over the winter. Since he had a battery from another plane nearby we hooked up my cable and it worked and he said "Your avionics guy has a problem with his cable".

That was my cheapest aviation bill so far!

I flew the 182 down to our mechanic to have the front strut on the 182 serviced as it was leaking air (but not fluid) during the negative temperature days this winter. Normally I would just drop it off but he said "You can hang around it won't take long". We put 4 cases of oil on the tail and it was up in the air ready for work. Over the course of about 15 minutes he kept pulling out more rings and finally had it out and poured out the fluid. 10 minutes later he had new orings and started putting it together. He just pushed the wheel up and had it draw fluid in from a bottle (I forget the order). All in he charged me 1.25hrs labor and some simple parts.

Part of that 1.25 was testing my Cessna jumper cable because while chatting I mentioned the side plug on the plane hadn't worked for the avionics guy over the winter. Since he had a battery from another plane nearby we hooked up my cable and it worked and he said "Your avionics guy has a problem with his cable".

That was my cheapest aviation bill so far!

Glenn D

Pre-takeoff checklist

servicing is usually $20, If you must service that often to rationalize that cost you should repair the strut.

Have used it 2x so far to adjust the nose height... it is not a cost issue,..... I like tools and having the ability to do it myself.. and my A&P has a big bottle in the back of the hangar that is hard to get to... So it is just easier.... Now I'm going to make a Bendix Mag timing tool as the ones at Aircraft Spruce is not worth paying $55 for.... I can make my own at no cost out of materials in the shop...

3393RP

En-Route

- Joined

- Oct 8, 2012

- Messages

- 4,044

- Display Name

Display name:

3393RP

I put together a Nitrogen setup for less than $150.. Small bottle, regulator hose and fitting... great to do my own when needed....

I have a small bottle of nitrogen sourced from Home Depot for $38, a pawn shop regulator was $18, and I already had plenty of hoses. I cut off a 10' piece, added the fittings (Home Depot again) and now I are ready to inflate stuff.

Tom-D

Taxi to Parking

- Joined

- Feb 23, 2005

- Messages

- 34,740

- Display Name

Display name:

Tom-D

I wouldn't trust that any farther than I could throw it.I have a small bottle of nitrogen sourced from Home Depot for $38, a pawn shop regulator was $18, and I already had plenty of hoses. I cut off a 10' piece, added the fittings (Home Depot again) and now I are ready to inflate stuff.

long time back I had two co-workers very seriously hurt by a cheap regulator and low pressure hose.

Tom-D

Taxi to Parking

- Joined

- Feb 23, 2005

- Messages

- 34,740

- Display Name

Display name:

Tom-D

Funny how far some will go to cheap it out.

when the right stuff ain't that expensive.

https://www.aircraftspruce.com/catalog/appages/phnx-blkbrd-hose.php?clickkey=27176

when the right stuff ain't that expensive.

https://www.aircraftspruce.com/catalog/appages/phnx-blkbrd-hose.php?clickkey=27176

NordicDave

En-Route

Gee, if I recall correctly, servicing two motorcycle fork legs, including R&R, new seals and fluid, and air pressure, was about 1.4 hours. And it didn't take that long. Certainly, on a Skyhawk, I could do it rather quickly. Perhaps there's something about that particular plane that kills most of a day.

On a Cessna; the cowling has to come off, counter-weighted over the horizontal stabilizer spar to tip nose up. Then remove the front tire, toggle linkage, shimmy dampener, disconnect the steering rods on the collar, depressurize the strut, pump out the fluid, remove the strut. Then there's inspection of the strut and tube. replace all the O-rings and other serviceable parts. Grease the roller bearing in collar, reinstall strut, then use a Bogart bottle to refill with the right amount of fluid, reassemble everything, reattach the the steering set-up, fill the strut with nitrogen. Put the plane back on it nose and adjust nitrogen level to set right height. Grease toggle links with grease gun. Put cowling back on.

I left stuff out like one of the O-rings that difficult to change, and cleaning everything while dissembled and more.

It's not fast or cheap and one reason so many planes have nearly collapsed nose gear. My job was 9 hours including rebuilding the shimmy dampener and toggle links. I did it with my MX and we worked all day.

-David

Timbeck2

Final Approach

If someone does it in 2.5 hours, they aren't doing it properly.

3393RP

En-Route

- Joined

- Oct 8, 2012

- Messages

- 4,044

- Display Name

Display name:

3393RP

I wouldn't trust that any farther than I could throw it.

long time back I had two co-workers very seriously hurt by a cheap regulator and low pressure hose.

It's a Victor regulator and the hose is double layer reinforced Goodyear. I think I'll be OK.

When I worked in IndyCar, we used 400 psi to run the wheel guns. I've seen a few accidents myself.

Tom-D

Taxi to Parking

- Joined

- Feb 23, 2005

- Messages

- 34,740

- Display Name

Display name:

Tom-D

Well, maybe, simple servicing 15 minutes, total rebuild possibly, that could turn into a couple weeks when parts are needed, or you have something strange.

If someone does it in 2.5 hours, they aren't doing it properly.

an old Fairchild with a broken spring, took me 6 months to find a #8 Acme spring, they don't have compressed air in them, just oil dampened spring.

unsafervguy

En-Route

I wouldn't trust that any farther than I could throw it.

long time back I had two co-workers very seriously hurt by a cheap regulator and low pressure hose.

I'm with you tom. The smallest reg that will do struts is about a 600 psi reg. Throw in a safety factor and I doubt that Home Depot fittings hav a 1500psi or better burst rating. My fill hose has a 4000 or so burst pressure hose.

Tom-D

Taxi to Parking

- Joined

- Feb 23, 2005

- Messages

- 34,740

- Display Name

Display name:

Tom-D

Actually didja know, when the tail is down on a 150-172, and the fluid is full, 20 pounds of N2 is all that is needed.I'm with you tom. The smallest reg that will do struts is about a 600 psi reg. Throw in a safety factor and I doubt that Home Depot fittings hav a 1500psi or better burst rating. My fill hose has a 4000 or so burst pressure hose.