davidm767

Pre-takeoff checklist

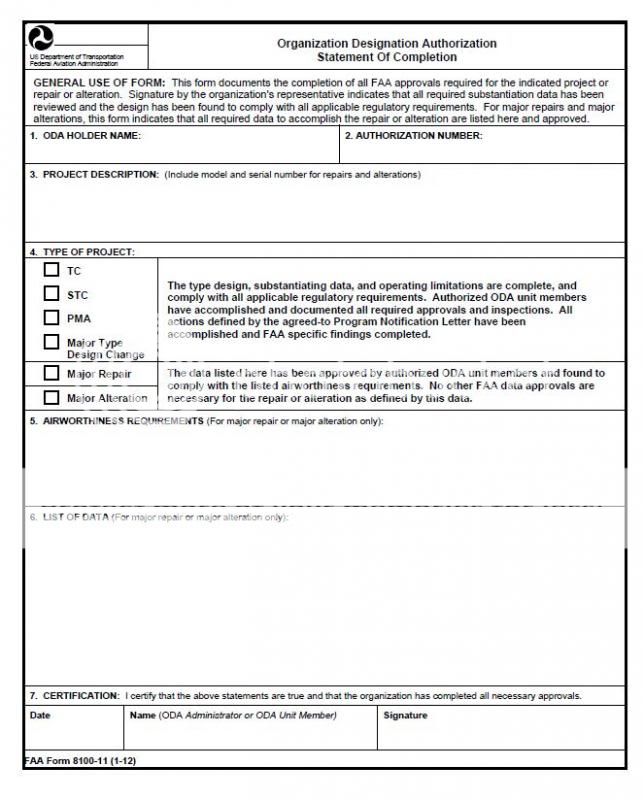

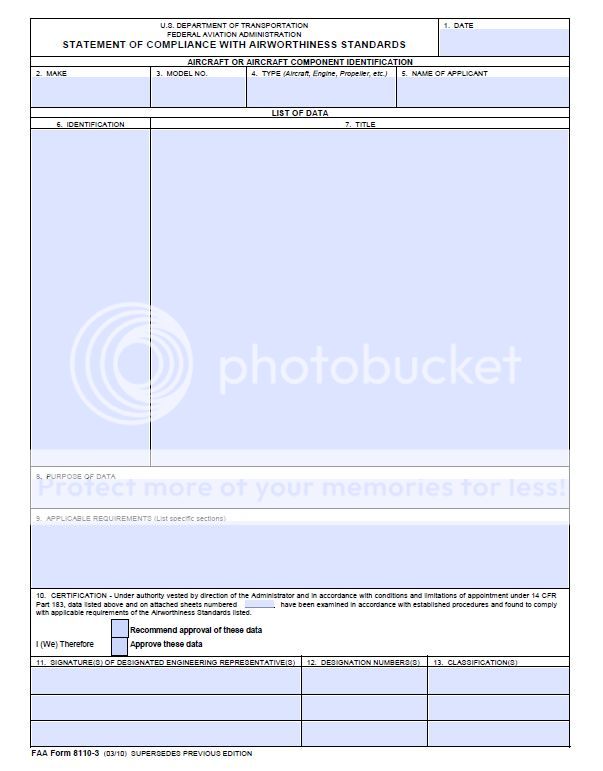

Got into a discussion in class today (decided to start MX school as a "third" of life crisis lol)). I know and agree that a 337 is necessary for changing out a fuse for a CB in a certified aircraft. Question is, what else may need to be changed? Can a bus that originally operate with fuses handle the operation of CBs, assuming the aircraft came with mixed fuses/CBs and was designed and built in mid 70s. Does this alteration require a STC? What would be required for paperwork on back of 337? I really appreciate input, as its likely an exercise ill do on my own aircraft.

Thanks

Dave

Thanks

Dave