plongson

Pre-Flight

How often are you guys actually servicing magnetos? I'm talking about early stuff...ours is 1962 Cherokee. The logs are a bit sketchy (IMHO) for the last 20 years and I'm not sure if they have (if ever) had any service. We recently had a mag drop go from acceptable to not, in a few short weeks.

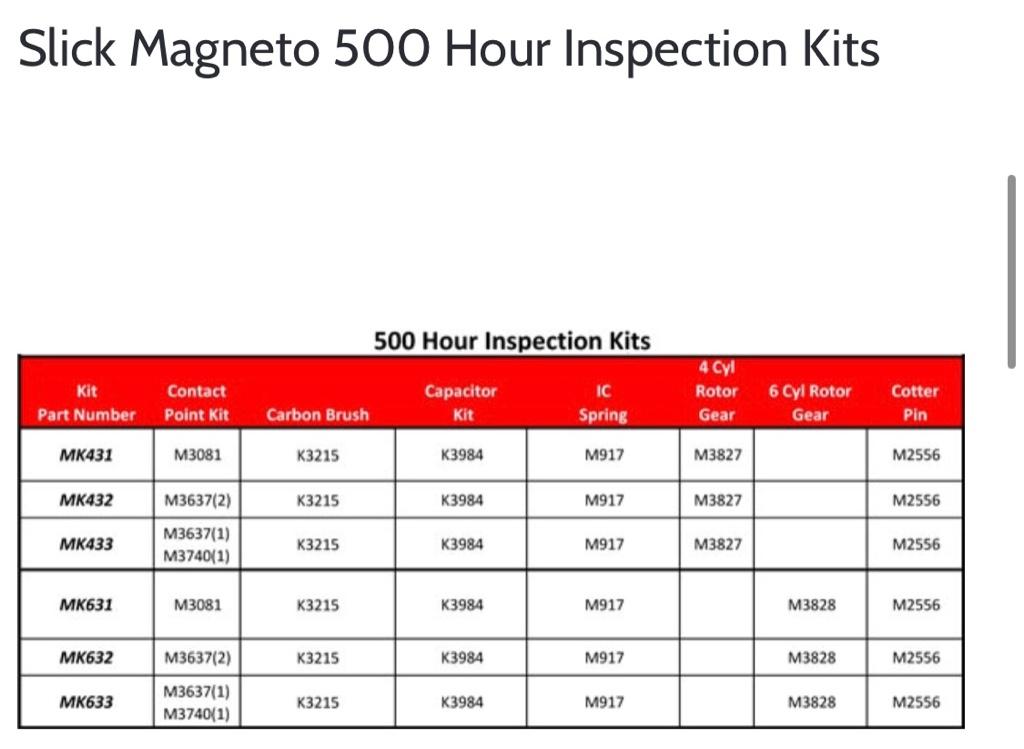

it's going in the shop tomorrow to have it looked at, and they think it might be simply timing. My research shows points and condenser a coil and magnet are also inside these units.

Back in the day, it was SOP to change points/condenser and plugs VERY often to keep the old school cars running well.

What's the opinion here??

it's going in the shop tomorrow to have it looked at, and they think it might be simply timing. My research shows points and condenser a coil and magnet are also inside these units.

Back in the day, it was SOP to change points/condenser and plugs VERY often to keep the old school cars running well.

What's the opinion here??