fiveoboy01

Pattern Altitude

I had a primer line fixed as mentioned in another thread. It broke off at the fitting at the cylinder head. I elected to have the entire line replaced, the one that goes around the rear of the crankcase to the #1 cylinder.

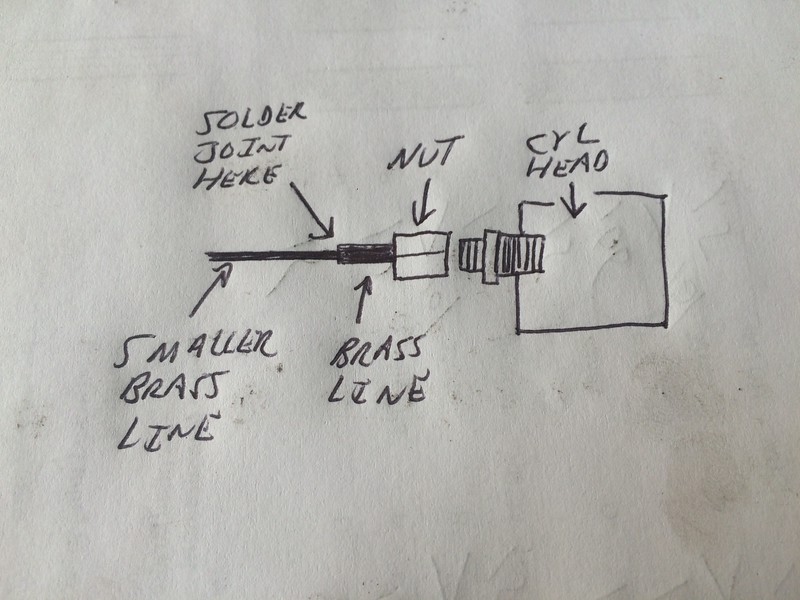

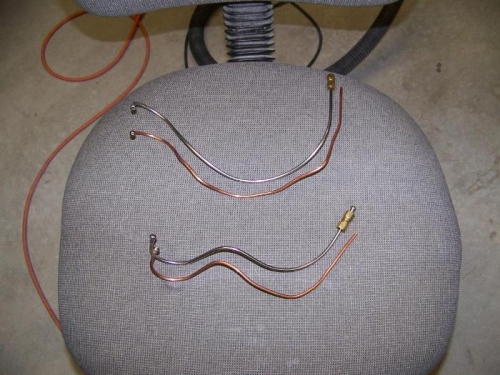

A new brass line was ran of the same size(1/8" I think) from the left to the right side of the crankcase... The fitting itself has an inch of brass tubing coming out of it that's the next size bigger, the long line was inserted into that tubing and they were soldered/brazed together.

I'm a bit suspicious of this repair, seems a little mickey-mouseish(it's like they didn't have the right size ferrule nut), but I'm not an A&P... what say you guys?

A new brass line was ran of the same size(1/8" I think) from the left to the right side of the crankcase... The fitting itself has an inch of brass tubing coming out of it that's the next size bigger, the long line was inserted into that tubing and they were soldered/brazed together.

I'm a bit suspicious of this repair, seems a little mickey-mouseish(it's like they didn't have the right size ferrule nut), but I'm not an A&P... what say you guys?