GlennAB1

Ejection Handle Pulled

- Joined

- Oct 5, 2015

- Messages

- 4,889

- Location

- Home will always be Vandalia, OH

- Display Name

Display name:

GlennAB1

True. They (Advisory Circulars) aren't mandatory.

What about a case where there is a single buss feeding all systems, through a single copper bar. The need to seperate the systems invokes the need to modify the copper buss bar, so that the avionics buss can be seperate from all other systems, and fed through the AV master switch, which is fed from the main buss.I do believe the addition of a AV-master would be a minor alteration, but should be documented for later reference. I see no need for the FAA to run the whole gambit of a field approval. the IA should be allowed to make this decision as to airworthiness of the minor change.

in cases like this. JMHO

What about a case where there is a single buss feeding all systems, through a single copper bar. The need to seperate the systems invokes the need to modify the copper buss bar, so that the avionics buss can be seperate from all other systems, and fed through the AV master switch, which is fed from the main buss.

I consider it to be a minor alteration. (but a major PITA) But it doesn't matter what I think, what would the FAA think?

Just because it is acceptable data, does not mean it applies to this application. This AC does not show you how a buss is supposed to be split, Nor does it tell you that splitting a buss is acceptable. Just because some routine is easy to do does not mean it is a minor alteration.For a part 91, single engine piston unpressurized airplane built under CAR 3 and some early amendments of 23?

http://www.faa.gov/documentLibrary/media/Advisory_Circular/AC 43.13-2B.pdf

You know well enough that is not how it is done.Yes, but each system comes off the bus with a separate feed from the copper bar, so all you are doing is inserting a switch and breaker/fuse in series with the wire feed. What is the major in that?

Jim

Yes, there are seperate circuit breakers, fed by a single buss bar. (in the scenerio I posted, 1969 PA28-140) But, there is no way to seperate the avionics breakers from the rest, without removing the buss bar, and either replacing it, or modifying it, so that the avionics are fed independently of the rest of the electrical system. Then (after the modification) there must be a feed line from the main buss to the AV master switch, then back to the new avionics buss.Yes, but each system comes off the bus with a separate feed from the copper bar, so all you are doing is inserting a switch and breaker/fuse in series with the wire feed. What is the major in that?

I've found, at least with a REASONABLE PMI (Principal Maintenance Inspector) that you have established a relationship with, if you've got a good plan backed up with well thought out calculations and data that they will approve damn near anything reasonable short of a cast iron bathtub drawn by a flock of black swans.

Jim

People,, When the FAA made the policy that the 43-13 could be used as acceptable data for alterations, they specified that it would not be used when the aircraft has support in the form of a manufacturer's manuals. they farther specified that the page and paragraph of the applying data would be quoted.

So... some one quote the acceptable data from the 43-13 that would be used to gain approval of the field approval.

What does a STC have to do with a field approval ?Your understanding of 41.13 is much different than mine. That doesn't explain how a note on a drawing references 43.13 practices for both structural fabrication and wiring that alters a 5 year old still in production jet. They STC holder wrote a drawing that covers the critical details needed and then just left it up to the installer to use 41.13 or OEM data to fill in the noncritical gaps.

With that last thought, I think you hit the nail on the head as to why it should be a major.One of the things I don't like about the master, besides the breaker being too big and in the wrong location, is the single point failure possibility.

You don't tell us much, the make and model aircraft would be good info. knowing the skit is to know what is normal wiring and what is not.I'm soliciting opinions.

I'm looking at the undocumented installation of an Avionics Master switch. It's a simple 35A current protected SPST switch in series with smaller breakers that power to all the Com, Nav, GPS, and XPDR gear on the airplane.

It does happen to be a 35A switch/breaker installed at the load end of a 12 AWG wire from the power bus. It is too big a breaker to protect that wire. At the load end, it protects only about the last 2"-3" of wire between the switch breaker and the other breakers. The 2ft of wire between the switch breaker and the power bus are completely unprotected.

I'm getting ready to pull it out, but I thought I'd see what consensus is. It's my own airplane, I'm still getting acclimated to the wild west world of GA coming from an airline perspective. I do appreciate the ability to share the experienced insights others.

You don't tell us much, the make and model aircraft would be good info. knowing the skit is to know what is normal wiring and what is not.

With that last thought, I think you hit the nail on the head as to why it should be a major.

Apologies Tom, it's a Grumman Tiger AA-5B. I didn't assume anyone would know specifics on any particular Type.

Glenn, Outside of the description in Part 43 Appendix A, I understand Major changes as those things likely to impact certification requirements and data specifically approved by the FAA, like flying qualities, engine performance, limitations etc. I don't have a feel for what the structures side of Major/Minor is.

I think reliability is important and electrical system reliability (and engine reliability) especially so in an airplane capable of IFR. I haven't specifically looked for a part 23 or part 25 certification reliability requirements.

Really, Car 3 or FAR 23 and 21 have no bearing on later modifications. (That is covered by 43-A) Car 3, FAR 21 & 23 only apply to certification of new product seeking a production certificate.

Think about it, did the load change simply by modifying the control of it.Tom, I think they do if you try to generalize what requires FAA involvement beyond application of part 43 Appendix A by a mechanic or IA.

Totally different set of rules your experiences don't apply here, don't cloud the issue by trying to applying them here.I've worked the last 20 years or so as an airline engineer.

I was trying to respond to Glenn's question.Totally different set of rules your experiences don't apply here, don't cloud the issue by trying to applying them here.

Read your insurance policy, many say the aircraft must be in an airworthy status when you fly, If it isn't there may be an issue collecting the money.Back to my first post; as long as nothing bad happens, it probably doesn't matter. If something bad happens, it matters, and if your name is on it it better be right. Is that why there's no documentation of the alteration?

Have your A&P-IA inspect it, see what paper they think it needs if any.No, as I stated earlier (maybe I was too verbose, I try to avoid that) I think the answer to my original question on my airplane is that it's probably FAA minor.

And when you did that, you brought many issues into the conversation that have no bearing on your question.I was trying to respond to Glenn's question.

BUT.... they do give you acceptable methods to comply with FAR 43.13.(Advisory Circulars) aren't mandatory.

Yes, I was responding to his statement or question. If the editor was friendlier, I'd show you but is isn't.And when you did that, you brought many issues into the conversation that have no bearing on your question.

Car 3 or FAR 23 and 21 have no bearing on later modifications.

Car 3, FAR 21 & 23 only apply to certification of new product seeking a production certificate.

Back to my first post; as long as nothing bad happens, it probably doesn't matter. If something bad happens, it matters, and if your name is on it it better be right. Is that why there's no documentation of the alteration?

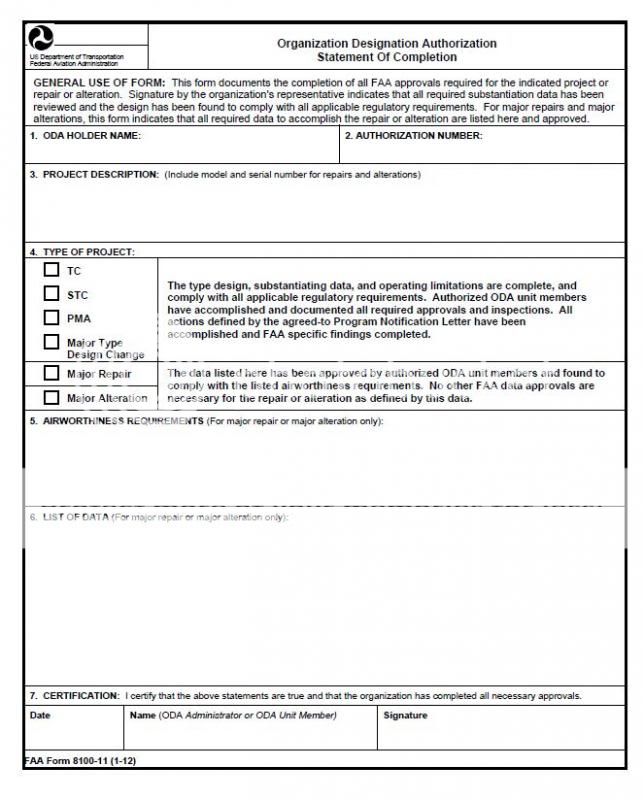

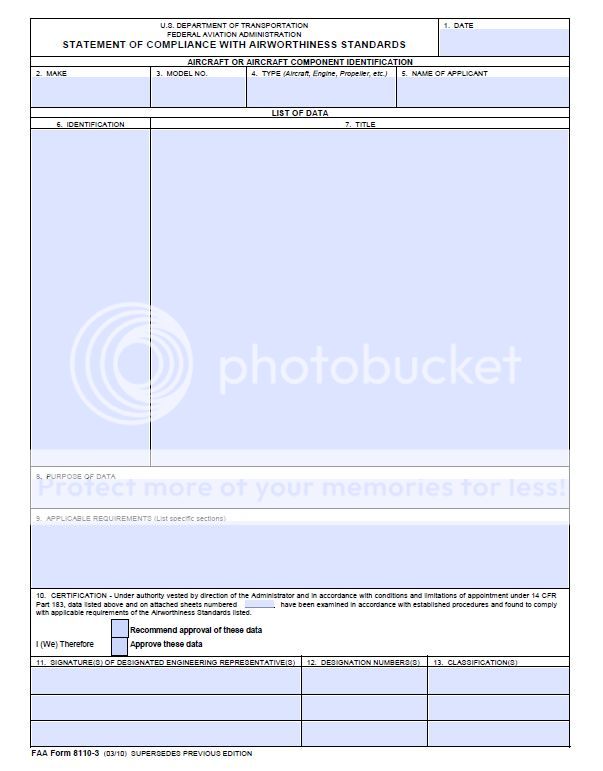

They do Tom. Anytime you get an FAA form 8100-11, 8100-9 or 8110-3 approving data to support a major alteration or major repair guess what that form is signifying? It is saying the data listed (drawing numbers etc) has met the regulations (almost always the regs listed on it are pulled directly from the ship's TCDS). We cannot (A&P or A&P IA) modify an airplane under part 43 in any way that would be contrary to regulations listed on that TCDS.

Have you forgotten what airworthiness is? or the phrase " or it's properly altered condition" what does that mean?

That's the part the IA is supposed to know, by researching the documentation in the aircraft history records.You just said :

Car 3 or FAR 23 and 21 have no bearing on later modifications.

If that were true, how is anyone supposed to know what a proper altered condition is?

Have you forgotten what airworthiness is? or the phrase " or it's properly altered condition" what does that mean?

OBTW the forms you mentioned only insure the data used to make certain repairs were in compliance with approved methods, they do not require the requirements of FAR 21/23 are complied with.

I see no connection between repair data and Certification requirements of new product. FAR 21&23. The forms you mentioned are used by DAR and FSDO to insure the data you are requesting to use is the proper method to do the repair.I'm not sure what you are trying to say really. Those forms are used for approving alteration and repair data.