bnt83

Final Approach

FWIW this O-320 I'm flying has gone from the worst engine I've flown behind to one of the best, and here's what was wrong:

#1. Had the WRONG carburetor in it. I'm not kidding. Sure it was an MA4-SPA but setting #10-3678-32 and not setting #10-5217 as recommended by Lycoming Service Instruction. A quick call to a carburetor shop reviled the 10-3678-32 runs MUCH MUCH richer (by 2 – 3 gallons GPH) than the 10-5217, the plug fouling problems confirmed that. I could find no long entry to suggest that carburetor was ever replaced with that 10-3678-32, so I assume it was factory installed.

With all the possible cooling issues in mind we ordered a rebuilt 10-5217 and requested it be set it to the highest fuel flow for that setting # tolerance.

#2. The Induction Leaks - The pipes that come out of the sump are swaged in meaning that they can vibrate loose and then start an induction leak. On a 1400 TTSN engine we found the forward two pipes loose in the sump casting. All the induction gaskets and rubber hoses were replaced at this time.

#3.One baffle spring broken

#4. Time the mags to the engine with a piston stop and the electronic protractor. Don’t use the timing marks on the ring gear and don’t use the wheel with weighted pointer degree wheel type timing disks.

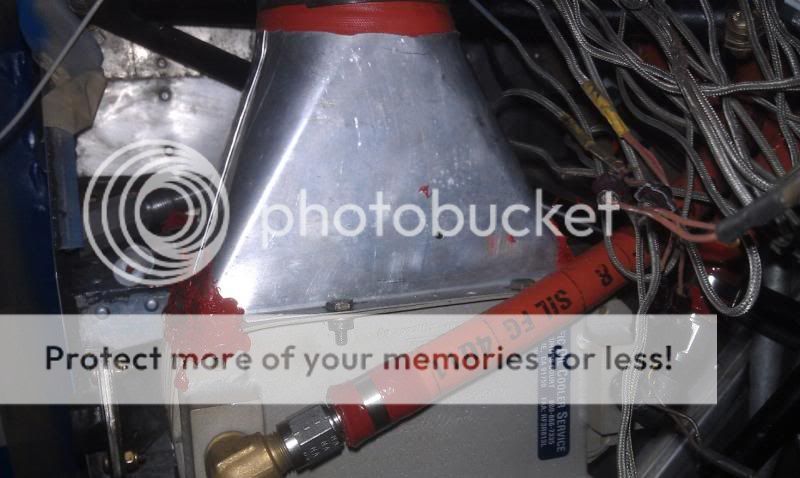

#5. Look in the cowling and see where the silicone baffle seals lay. They need to lie toward the high pressure above the engine not away.

#1. Had the WRONG carburetor in it. I'm not kidding. Sure it was an MA4-SPA but setting #10-3678-32 and not setting #10-5217 as recommended by Lycoming Service Instruction. A quick call to a carburetor shop reviled the 10-3678-32 runs MUCH MUCH richer (by 2 – 3 gallons GPH) than the 10-5217, the plug fouling problems confirmed that. I could find no long entry to suggest that carburetor was ever replaced with that 10-3678-32, so I assume it was factory installed.

With all the possible cooling issues in mind we ordered a rebuilt 10-5217 and requested it be set it to the highest fuel flow for that setting # tolerance.

#2. The Induction Leaks - The pipes that come out of the sump are swaged in meaning that they can vibrate loose and then start an induction leak. On a 1400 TTSN engine we found the forward two pipes loose in the sump casting. All the induction gaskets and rubber hoses were replaced at this time.

#3.One baffle spring broken

#4. Time the mags to the engine with a piston stop and the electronic protractor. Don’t use the timing marks on the ring gear and don’t use the wheel with weighted pointer degree wheel type timing disks.

#5. Look in the cowling and see where the silicone baffle seals lay. They need to lie toward the high pressure above the engine not away.