SoCal 182 Driver

Line Up and Wait

- Joined

- Sep 11, 2019

- Messages

- 995

- Display Name

Display name:

SoCal 182 Driver

Friends -

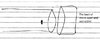

Please take a look at my very crude drawing below. What I have is basically two tubes, with one sliding over the other. The smaller (inner tube) is pre-drilled for a 1/8" roll pin that is intended to go through the outer tube, both walls of the inner tube, and then out the other side of the outer tube. The roll pin then secures the outer tube to the inner tube.

The problem I have is that the outer tube is not pre-drilled for the roll pin. Can anyone tell me how to mark the outer tube so I can drill it?

Thanks.

Please take a look at my very crude drawing below. What I have is basically two tubes, with one sliding over the other. The smaller (inner tube) is pre-drilled for a 1/8" roll pin that is intended to go through the outer tube, both walls of the inner tube, and then out the other side of the outer tube. The roll pin then secures the outer tube to the inner tube.

The problem I have is that the outer tube is not pre-drilled for the roll pin. Can anyone tell me how to mark the outer tube so I can drill it?

Thanks.