Mooney Fan

Line Up and Wait

Brought home a 75' 150M the other day. 13.5 SMOH with new Superior Cylinders. Checked filter at 10 hours with no metal noted. Good compressions. Still working mineral oil and waiting for oil burn to stabilize. Right now its blowing anything over 4qts on the belly.

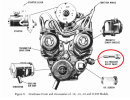

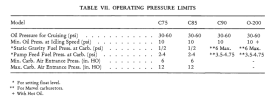

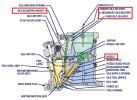

Oil pressure is OK but that oil temp reading at 55F degrees, 2500 rpm seems high. But then again, I've never broke in a fresh engine and cylinders. The engine has new Airform baffles. Looking into the cowl air inlets the baffle blocks an awful lot of those cylinders up front. Plus, someone siliconed the back of the baffle to the cylinder base. Typical? I can't find any detailed guidance on that.

Looks like I'm running at 210 degrees? We plan to check he gauge first if things don't cool down

Thanks

View attachment 116904

Oil pressure is OK but that oil temp reading at 55F degrees, 2500 rpm seems high. But then again, I've never broke in a fresh engine and cylinders. The engine has new Airform baffles. Looking into the cowl air inlets the baffle blocks an awful lot of those cylinders up front. Plus, someone siliconed the back of the baffle to the cylinder base. Typical? I can't find any detailed guidance on that.

Looks like I'm running at 210 degrees? We plan to check he gauge first if things don't cool down

Thanks

View attachment 116904

Attachments

Last edited: