TFulwider

Pre-takeoff checklist

- Joined

- Jul 29, 2015

- Messages

- 193

- Display Name

Display name:

Terry

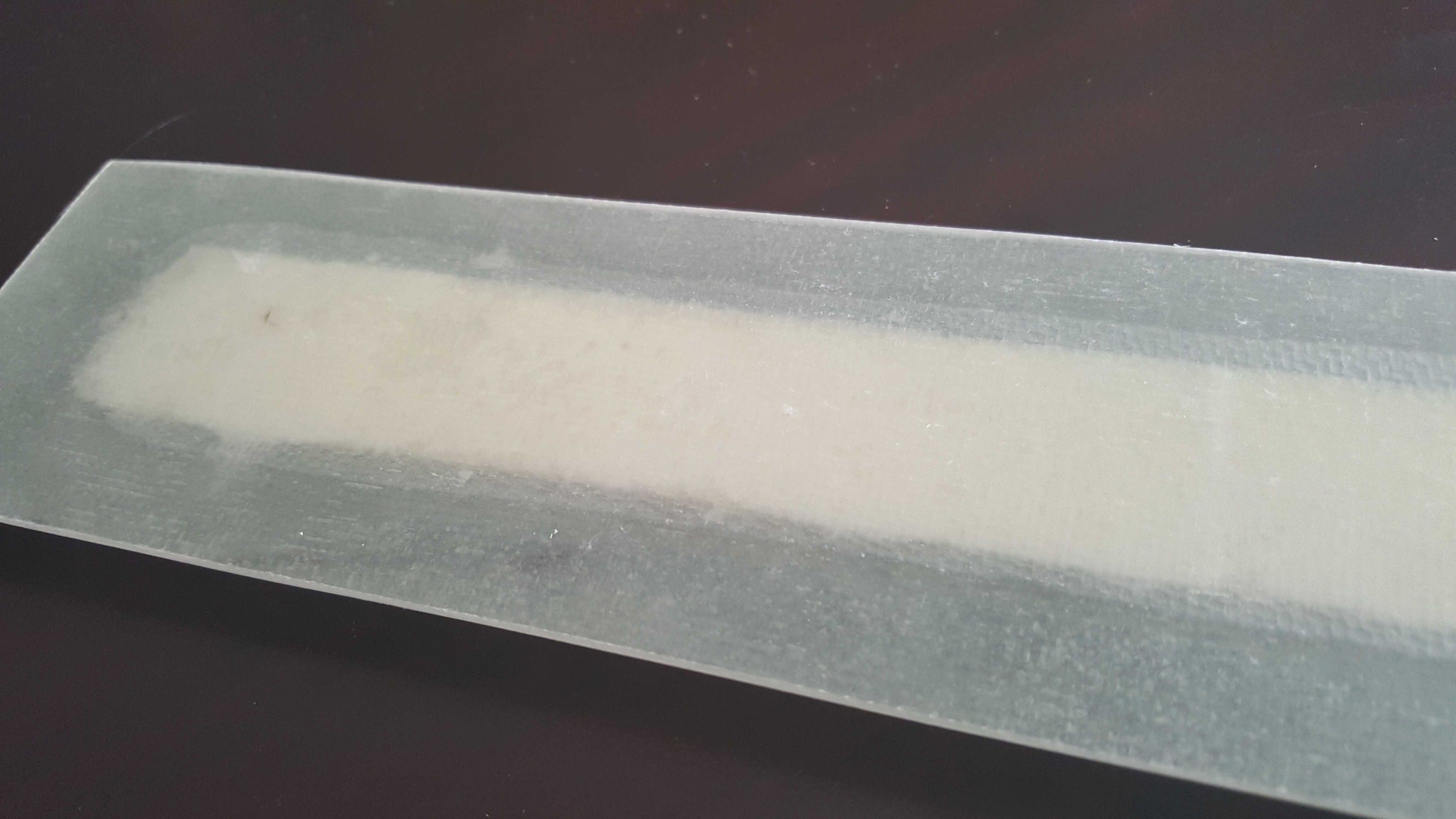

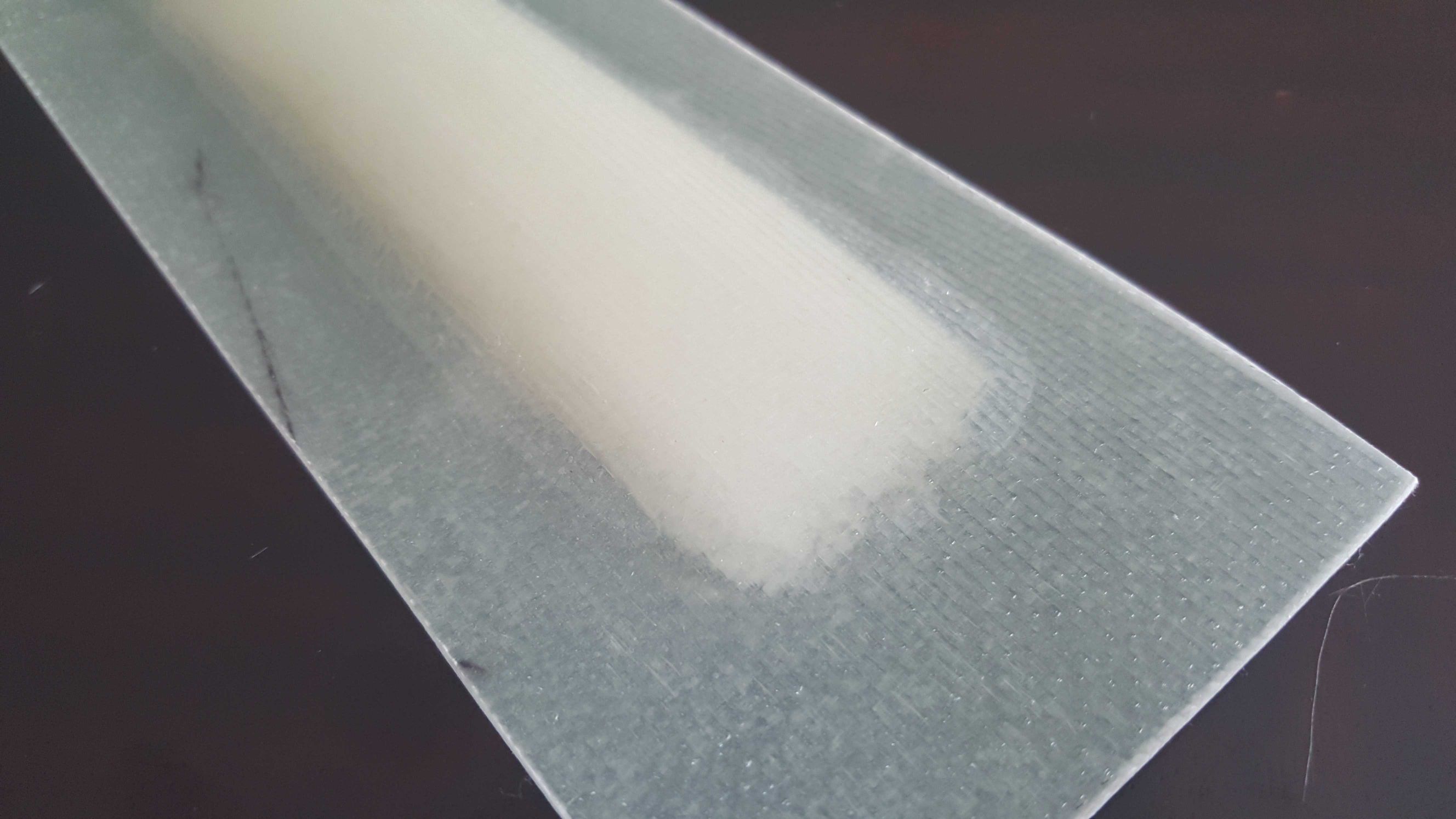

I'm not building actual parts yet so I still can't call myself a plane builder, but it's getting close! Aircraft Spruce delivered my practice kit last night. I was actually giddy opening a box full of fiberglass, resin and foam! It'll be a week or two before I have a big enough block of time to sit down and focus on it, but it I am excited to get going.