petrolero

Pattern Altitude

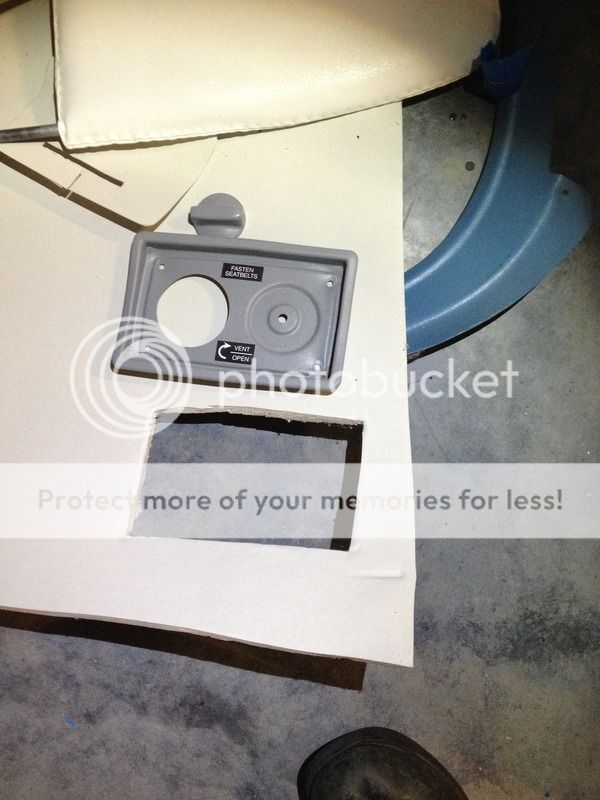

The rear air vents on my 182 are old and leaky (and the tubing is pretty rotten). These are the rectangular style vents that rotate and also have vanes. I have searched for these things on google and can't even find an image of them. I don't have a pic right now either but I may get out to the airplane this weekend.

My question is whether anyone knows of a replacement for those dumb things. They suck. Actually they blow. Constantly. We can't shut them off completely and they make the kids cold back there sometimes.

I'd love to install those eyeball style butterfly valves but I haven't found any that are drop-in replacements for the stupid Cessna vents. My mechanic and I talked about just buying butterfly valves and then fabricating some sheet metal to affix them to the plenum. I never pulled the trigger on that because it sounded like a Cla$s 1 PITA.

Has anyone dealt with replacing or repairing those old vents? Aftermarket or Cessna or homebrewed booty fab?

Thanks!

My question is whether anyone knows of a replacement for those dumb things. They suck. Actually they blow. Constantly. We can't shut them off completely and they make the kids cold back there sometimes.

I'd love to install those eyeball style butterfly valves but I haven't found any that are drop-in replacements for the stupid Cessna vents. My mechanic and I talked about just buying butterfly valves and then fabricating some sheet metal to affix them to the plenum. I never pulled the trigger on that because it sounded like a Cla$s 1 PITA.

Has anyone dealt with replacing or repairing those old vents? Aftermarket or Cessna or homebrewed booty fab?

Thanks!