The proper thing is to replace the worn pieces. Time and money, but might be cheaper than a whole exchange elevator.

Those bushing will be frequently found loose. Mechanics somehow think that the elevator is supposed to pivot on the bolt, so they don't torque it up. This applies to the rudder hinges as well. On the Cessna 180,185 and oldest 182s, the trim system moves the leading edge of the stabilizer up and down, and the aft end pivots on a similar setup in the tailcone just ahead of the rudder. Mechanics leave those bolts loose, too, and they chomp out the holes in some VERY expensive structural components. There is minimal material around those holes, so any slop is bad. Recently someone came up with STC'd short sections of the expensive "hockey stick" angles to repair that worn-out section. It's important stuff, as a failure there would cause a loss of control of the airplane.

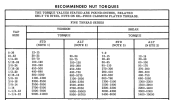

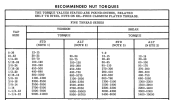

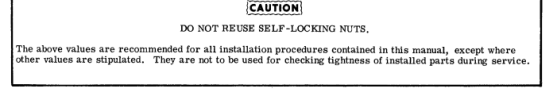

Service Manuals are published to prevent stupid mistakes like this. Right up front in Cessna's anuals we have this:

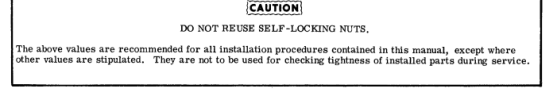

At the bottom of that page there is this:

Those 1/4" bolts and nuts are to be torqued for tension loads to capture that bushing, or "spacer" as Cessna calls it. 50 to 70 inch-pounds. There is no other stipulated torque on the page showing the assembly of those hinges, to the table above applies.

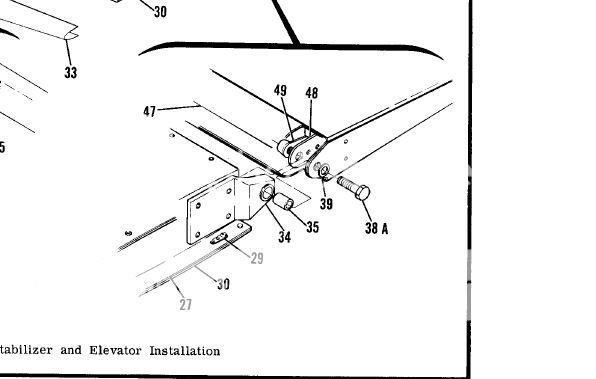

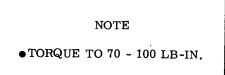

The 180/185 manual has, on the stabilizer installation page, this:

See the black dot next to the 1/4" hinge bolt, #14? At the bottom of the page, they put this:

Not loose. Not 50 to 70 inch-pounds, either. They want it tight, 70 to 100. They don't want that bolt moving in the structure.