cbrennanmx

Filing Flight Plan

- Joined

- Nov 10, 2023

- Messages

- 1

- Display Name

Display name:

Caleb Brennan

O-200 Cessna 150

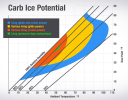

Hey there, and I am super excited to be on this forum. I really want some advice on an issue that I am having, well seems to me an issue. Sorry for long post but want to paint the full picture. I got a 150M (O200) that I have been using to build time, 400 hours of trouble free issues, and than out of no where, I would get a “hiccup” In the engine. This would occur at cruise, and appear almost that I had the mixture out too much and it coughed. I would go to place carb heat on, thinking carb ice but it would fix itself instantly. Then, flying along at 3000FT, I had the same thing occur, but this time, it lasted for several seconds. I prepared for an off-airport landing as I assumed that I had just lost an engine. I lost about 600RPM, and placed carb heat on, during this time, power was restored shortly after and I flew it to an airport to inspect. No vibrations, so I did not suspect a stuck valve, as it was the same symptoms of pulling mixture out too far. Carb icing was probable according to the chart at glide power, but was odd as I have never experienced this in cruise power. Spoke to mechanic, and he swore it was carb icing. Conditons have been colder here and high humidity, so I carried on. I got the same symptoms as a “hiccup” lasting for a second or two about twice since then, and one more event where it appeared I lost several RPM. This time, I pulled carb heat and it instantly fixed it. Not sure if it was a coincidence or what, but I thought it was odd to instantly fix ice, as it has to defrost, and run worse once it turns to water. Fast forward to today, climbing out (carb ice prob chart says high prob on cruise this time) the engine feels like its loosing power, and sure enough, I get what feels like trying to advance the throttle when it is too far leaned, there was a good shake that it had this time. It goes on for a while, and I turn immediately to the airport to come back. Pulled carb heat, and I do not recall when it was resolved, but it fixed itself. I also pulled power back to minimize the shaking, and landed. Mechanic again swears it is carb ice given the conditions, but I’ve never had this happen on full power. I asked if there is anything I could check, and he said it is virtually impossible to pinpoint the issue, and swears carb ice. What is yawls thoughts? Motor is about 2300TBO, great numbers and no issues. Just want honest advice if it sounds like a sticking valve or what. I ran it since this, mechanic came out and said it didn’t sound like a valve was sticking, and I flew it in the pattern once and no issues…

Only thing I need to replace I know is worn spark plugs. Mechanic stated to plan to replace them soon as they were pretty worn after he cleaned them. Really want some opinions, thanks to all.

Hey there, and I am super excited to be on this forum. I really want some advice on an issue that I am having, well seems to me an issue. Sorry for long post but want to paint the full picture. I got a 150M (O200) that I have been using to build time, 400 hours of trouble free issues, and than out of no where, I would get a “hiccup” In the engine. This would occur at cruise, and appear almost that I had the mixture out too much and it coughed. I would go to place carb heat on, thinking carb ice but it would fix itself instantly. Then, flying along at 3000FT, I had the same thing occur, but this time, it lasted for several seconds. I prepared for an off-airport landing as I assumed that I had just lost an engine. I lost about 600RPM, and placed carb heat on, during this time, power was restored shortly after and I flew it to an airport to inspect. No vibrations, so I did not suspect a stuck valve, as it was the same symptoms of pulling mixture out too far. Carb icing was probable according to the chart at glide power, but was odd as I have never experienced this in cruise power. Spoke to mechanic, and he swore it was carb icing. Conditons have been colder here and high humidity, so I carried on. I got the same symptoms as a “hiccup” lasting for a second or two about twice since then, and one more event where it appeared I lost several RPM. This time, I pulled carb heat and it instantly fixed it. Not sure if it was a coincidence or what, but I thought it was odd to instantly fix ice, as it has to defrost, and run worse once it turns to water. Fast forward to today, climbing out (carb ice prob chart says high prob on cruise this time) the engine feels like its loosing power, and sure enough, I get what feels like trying to advance the throttle when it is too far leaned, there was a good shake that it had this time. It goes on for a while, and I turn immediately to the airport to come back. Pulled carb heat, and I do not recall when it was resolved, but it fixed itself. I also pulled power back to minimize the shaking, and landed. Mechanic again swears it is carb ice given the conditions, but I’ve never had this happen on full power. I asked if there is anything I could check, and he said it is virtually impossible to pinpoint the issue, and swears carb ice. What is yawls thoughts? Motor is about 2300TBO, great numbers and no issues. Just want honest advice if it sounds like a sticking valve or what. I ran it since this, mechanic came out and said it didn’t sound like a valve was sticking, and I flew it in the pattern once and no issues…

Only thing I need to replace I know is worn spark plugs. Mechanic stated to plan to replace them soon as they were pretty worn after he cleaned them. Really want some opinions, thanks to all.