keb0

Filing Flight Plan

- Joined

- Aug 20, 2023

- Messages

- 19

- Display Name

Display name:

keb0

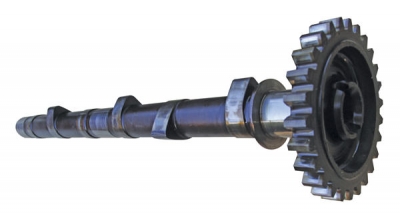

Looking at a potential AC located in Ak to purchase; a 2000 model with 800 TTSN on the 0-360 and airframe. No known or documented damage history. Floats and wheels seasonally. One owner since new, a very conservative pilot owner. Lifelong hangar queen, appears very well maintained. Inspection and borescope scheduled. Question is, would the low frequency usage on the 23 year old engine make it likely it will not make TBO or beyond? These hours averages out to 2.9 hrs per month over the life of the engine. This was typically one flight roundtrip per month. Would you anticipate corrosion issues or significant oil leaks in near future? My last bird (0-320) made it to 2400 hrs under close scrutiny before cam wear required a rebuild, but was flown much more frequently. I plan to fly a little more than average but not prolonged hard use; 25-40 hrs per month in the summer months, little less each winter. Comments, experiences? Thanks

Last edited: