Timbeck2

Final Approach

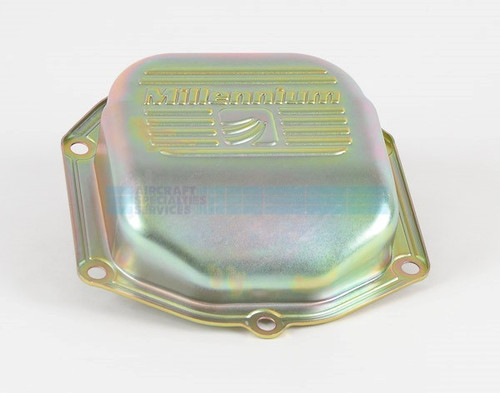

It was discovered at the last annual that my engine didn't have thrust buttons installed on the rocker shafts. I ordered the parts and installed them then discovered that the rocker cover won't fit over the thrust buttons. After a little research I discovered that on my 1970 era engine, they used longer rocker shafts and didn't use the thrust buttons. My choices are: A leave it as is, B install shorter rocker shafts C install different rocker covers.

Anyone else have this issue...if it is an issue?

Anyone else have this issue...if it is an issue?