Arrow3_Dawg

Filing Flight Plan

- Joined

- Feb 1, 2019

- Messages

- 14

- Display Name

Display name:

John B

Good evening,

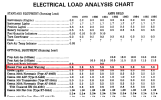

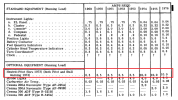

I have a Cessna 182P and for the second time in 9 months, the alternator circuit breaker popped after having the pitot heat turned on. The 15amp pitot heat breaker did not pop. The alternator breaker is a 60amp breaker and it popped after having the pitot heat on for about 20 minutes. According to the engine monitor, the system voltage dropped from the normal 13.4v down to 12.9 volts almost immediately after turning the pitot heat on. The total electrical load at the time was way less than 60amps. I turned off the pitot heat and reset the breaker then turned pitot heat back on. I did not leave the heat on for long as I was not in continuous IMC. Is this indicative of a bad voltage regulator or the pitot heat element going bad?

Thanks!

JB

I have a Cessna 182P and for the second time in 9 months, the alternator circuit breaker popped after having the pitot heat turned on. The 15amp pitot heat breaker did not pop. The alternator breaker is a 60amp breaker and it popped after having the pitot heat on for about 20 minutes. According to the engine monitor, the system voltage dropped from the normal 13.4v down to 12.9 volts almost immediately after turning the pitot heat on. The total electrical load at the time was way less than 60amps. I turned off the pitot heat and reset the breaker then turned pitot heat back on. I did not leave the heat on for long as I was not in continuous IMC. Is this indicative of a bad voltage regulator or the pitot heat element going bad?

Thanks!

JB