Ed Haywood

En-Route

BLUF: can I replace the fuel pressure gauge in my 78 Decathlon with a fuel flow totalizer?

I would like to get rid of the mechanical fuel pressure gauge. I don't like having a pressurized fuel line in the cockpit, especially in an aerobatic aircraft. Also the gauge is worthless because the needle jumps so much due to engine-driven fuel pump pulses. If I drain the gauge line to introduce an air buffer, the pulses are damped out, but the problem returns after a few aerobatic flights.

There are few good options for a stand-alone electric gauge and sender. Most of the gauges available are limited to 15 or 30 psi, and my AFM specifies a green arc to 45 PSI. UMA does make a TSO gauge/sender with a range of 60 PSI, but it is quite pricey at $500.

I'm not ready to drop $4K for a full blown engine monitor, but there are a few smaller bar graph monitors for under $2K that include fuel flow, most notably the Insight G2. There are also several fuel flow totalizers available in the $500 range.

FAR 23 says about required powerplant instruments:

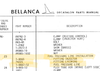

A fuel pressure gauge is listed in my AFM as required equipment. However, the TCDS has been updated over the years to include other options. Here is what the factory shared as current as of 2015:

I would like to get rid of the mechanical fuel pressure gauge. I don't like having a pressurized fuel line in the cockpit, especially in an aerobatic aircraft. Also the gauge is worthless because the needle jumps so much due to engine-driven fuel pump pulses. If I drain the gauge line to introduce an air buffer, the pulses are damped out, but the problem returns after a few aerobatic flights.

There are few good options for a stand-alone electric gauge and sender. Most of the gauges available are limited to 15 or 30 psi, and my AFM specifies a green arc to 45 PSI. UMA does make a TSO gauge/sender with a range of 60 PSI, but it is quite pricey at $500.

I'm not ready to drop $4K for a full blown engine monitor, but there are a few smaller bar graph monitors for under $2K that include fuel flow, most notably the Insight G2. There are also several fuel flow totalizers available in the $500 range.

FAR 23 says about required powerplant instruments:

(4) For each pump-fed engine, a means:

(i) That continuously indicates, to the pilot, the fuel pressure or fuel flow; or

(ii) That continuously monitors the fuel system and warns the pilot of any fuel flow trend that could lead to engine failure.

(i) That continuously indicates, to the pilot, the fuel pressure or fuel flow; or

(ii) That continuously monitors the fuel system and warns the pilot of any fuel flow trend that could lead to engine failure.

A fuel pressure gauge is listed in my AFM as required equipment. However, the TCDS has been updated over the years to include other options. Here is what the factory shared as current as of 2015:

Last edited:

It would be very poor design not to have one as it not only damps the pulses but also restricts how much fuel could flow if tube between the restrictor and the gauge fails (or the gauge itself fails due to the constant pulsing, a real risk). Same thing is used with a mechanical oil pressure gauge.

It would be very poor design not to have one as it not only damps the pulses but also restricts how much fuel could flow if tube between the restrictor and the gauge fails (or the gauge itself fails due to the constant pulsing, a real risk). Same thing is used with a mechanical oil pressure gauge.