You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Who's Building What?

- Thread starter Geico266

- Start date

Todd Copeland

Pre-takeoff checklist

Todd Copeland

Pre-takeoff checklist

Dave Krall CFII

Final Approach

- Joined

- Mar 4, 2005

- Messages

- 5,022

- Location

- Seattle WA

- Display Name

Display name:

Dave Krall CFII SEL SES, Cmcl HELI

I have towed with two supercubs one had 180hp the other was Supercub Serial #1. It had been converted from 90hp to 150hp.

Brian

It really does take 180 hp to make them perform in the "Super" range.... still fairly good planes either way.

Dave Krall CFII

Final Approach

- Joined

- Mar 4, 2005

- Messages

- 5,022

- Location

- Seattle WA

- Display Name

Display name:

Dave Krall CFII SEL SES, Cmcl HELI

Slick lookin paint and plane for sure:

Staying motivated is a huge deal! Start by committing to clean off the work bench and put away all the tools. Then commit at least 5 mins a day in the shop, even if it is just to look at the plans. Once I got started I was amazed at what I perceived as a huge project was an hour of work. Now that the weather is nice get after it!

My RV-12 parked at the Van's tent at SnF 2010.

AEROBAT

Pre-takeoff checklist

I am building an Air Bike, fuselage 90% done. I have to repair two ribs and recover both wings. I will use Poly fiber as I have a bunch left from recovering my son's Avid Flyer.

Just recently rebuilt the cooling plenum and changed the intercylinder baffling on the O-235 in my Midget Mustang. I changed the baffling to the way the Formula One people are doing it. Huge difference, now all jugs are reading within 10 degrees.

Just recently rebuilt the cooling plenum and changed the intercylinder baffling on the O-235 in my Midget Mustang. I changed the baffling to the way the Formula One people are doing it. Huge difference, now all jugs are reading within 10 degrees.

Bill Watson

En-Route

DaleB

Final Approach

Last weekend I drove 2300miles round trip to pick up my RV-7A project. The box o' tools from The Yard arrived this afternoon, so right now I'm building a Van's tool box.  In a few days, once I've gotten my rivet-fu to the point where I won't mess things up, I'll start to work on the RV.

In a few days, once I've gotten my rivet-fu to the point where I won't mess things up, I'll start to work on the RV.

If I don't get enough experience/confidence from the tool box, I'll probably order the other practice kit and bang on that for a while.

If I don't get enough experience/confidence from the tool box, I'll probably order the other practice kit and bang on that for a while.

yakdriver

Cleared for Takeoff

- Joined

- Aug 29, 2011

- Messages

- 1,200

- Location

- Twin Falls, Idaho

- Display Name

Display name:

yellow peril

Last weekend I drove 2300miles round trip to pick up my RV-7A project. The box o' tools from The Yard arrived this afternoon, so right now I'm building a Van's tool box.In a few days, once I've gotten my rivet-fu to the point where I won't mess things up, I'll start to work on the RV.

If I don't get enough experience/confidence from the tool box, I'll probably order the other practice kit and bang on that for a while.

Dale, Practice with different pressure settings on the rivet gun. You will use a lower setting for the -3 rivets than the 4s. Also if you don't have one already get a tungsten bucking bar. They are a little spendy but worth every penny. Now that you have the kit do something on it EVERY DAY! That is the only way you can get a project like this finished. And have fun, it is a great learning experience. Don

DaleB

Final Approach

I am very happy to say that last night I did my very first work on the actual airplane.  I finished the Van's toolbox kit, admired my work for a minute (actually, stood there and looked at the flaws I knew about) and started to work.

I finished the Van's toolbox kit, admired my work for a minute (actually, stood there and looked at the flaws I knew about) and started to work.

The kit's previous owner had done most of the work on the empennage, but didn't finish it. I decided to start with the electric trim servo, so last night I got those parts drilled, deburred, dimpled and ready for primer. Today I'll start to work on the trim tab itself -- I want to have those parts ready to prime before setting up to shoot primer.

Banging rivets isn't bad. The 1/8" are easier to do well with the rivet gun, the 3/32" are easier with the squeezer. Still, I'm holding off on riveting the plane parts until my set of rivet gauges arrive Monday or Tuesday. And yeah, I'm looking for a deal I can't refuse on a tungsten bucking bar.

The kit's previous owner had done most of the work on the empennage, but didn't finish it. I decided to start with the electric trim servo, so last night I got those parts drilled, deburred, dimpled and ready for primer. Today I'll start to work on the trim tab itself -- I want to have those parts ready to prime before setting up to shoot primer.

Banging rivets isn't bad. The 1/8" are easier to do well with the rivet gun, the 3/32" are easier with the squeezer. Still, I'm holding off on riveting the plane parts until my set of rivet gauges arrive Monday or Tuesday. And yeah, I'm looking for a deal I can't refuse on a tungsten bucking bar.

yakdriver

Cleared for Takeoff

- Joined

- Aug 29, 2011

- Messages

- 1,200

- Location

- Twin Falls, Idaho

- Display Name

Display name:

yellow peril

Dale, If its not too late go with the manual elevator trim. It works a lot better that the electric trim. I have flown over 20 different RVs of all the models and I hate the electric trim. Also you are likely to have trouble with the electric. Also the manual aileron trim works great. The trim tab is one of the toughest things to build on the whole airplane. Luckily new parts for it are cheap. Hardly anyone gets a real nice one the first time. Don

DaleB

Final Approach

I decided to order a new trim tab skin. I took a shot at it last night. It's really not too bad, and serviceable, but less than the quality I want. I'm not being a perfectionist, I just made some crappy bends. So... it's a cheap part, I'll take another shot at it. I think I'll cut the tabs off instead of folding them over, and rivet in "riblets" on the ends. It seems to be a popular solution.

If I don't like the response of the electric trim, I can always change the servo motor speed and/or travel. I'm not too worried about it.

If I don't like the response of the electric trim, I can always change the servo motor speed and/or travel. I'm not too worried about it.

yakdriver

Cleared for Takeoff

- Joined

- Aug 29, 2011

- Messages

- 1,200

- Location

- Twin Falls, Idaho

- Display Name

Display name:

yellow peril

I decided to order a new trim tab skin. I took a shot at it last night. It's really not too bad, and serviceable, but less than the quality I want. I'm not being a perfectionist, I just made some crappy bends. So... it's a cheap part, I'll take another shot at it. I think I'll cut the tabs off instead of folding them over, and rivet in "riblets" on the ends. It seems to be a popular solution.

If I don't like the response of the electric trim, I can always change the servo motor speed and/or travel. I'm not too worried about it.

Dale, don't cheat now. You can bend those tabs perfectly with a little practice. That is one thing that other builders look at to judge the quality of workmanship. The canopy and cowl fit are another area and also the wing fairings. These are all areas that are hard to do and require finesse. Don

DaleB

Final Approach

The more I thought about it -- the more I thought I could do it well as designed. Of course there is some debate as to what the "right" way is! A lot of people think bending those tabs over is a kludgy way to do it, and the ends should be done like any other control surface end, with a riveted rib. I really don't think it makes the slightest practical difference. I could carve a trim tab out of maple and it would fly until long after I have to hang it up. At this stage, though, I'm less willing to write off Van's engineering and do it my way -- there will be plenty of that in later stages, I'm sure.

In the end, I decided that with a little more work I could make the ends perfect, and according to plans. The "according to plans" part isn't a huge issue, really, but I do want to see if I can do it. The only deviation I am considering is using solid rivets instead of pulled in the end tabs. I want to see if I can get a special purpose fabricated bucking bar in there and smack them down right. I really don't like pulled rivets much. If I can't get the solid rivets set right I can always drill them out and pull some CS4-4s.

In the end, I decided that with a little more work I could make the ends perfect, and according to plans. The "according to plans" part isn't a huge issue, really, but I do want to see if I can do it. The only deviation I am considering is using solid rivets instead of pulled in the end tabs. I want to see if I can get a special purpose fabricated bucking bar in there and smack them down right. I really don't like pulled rivets much. If I can't get the solid rivets set right I can always drill them out and pull some CS4-4s.

... It works a lot better that the electric trim. I have flown over 20 different RVs of all the models and I hate the electric trim. Also you are likely to have trouble with the electric. ..... Don

Hi Don.... I am curious.. I have been running the electric trim set up on my 801 for 10 years or so..... Not a hint of problems and I use it on every flight....

What troubles are you referring to ?

Thanks in advance.

Ben.

tmyers

En-Route

Swwweeeeeet,

When you gonna post a pic of the T-Craft?

When you gonna post a pic of the T-Craft?

Howard Wilson

Line Up and Wait

Hi Tim,

The T-craft is still sitting in the barn. The cowling conversion has been a pain. I'm getting there....slowly. Hard part now is finding time to work on it, as we are doing a couple of long term major projects on the farm. I'll post a few older pics here for fun. Howard

The T-craft is still sitting in the barn. The cowling conversion has been a pain. I'm getting there....slowly. Hard part now is finding time to work on it, as we are doing a couple of long term major projects on the farm. I'll post a few older pics here for fun. Howard

Attachments

Howard Wilson

Line Up and Wait

VanDy

Cleared for Takeoff

Swwweeeeeet,

When you gonna post a pic of the T-Craft?

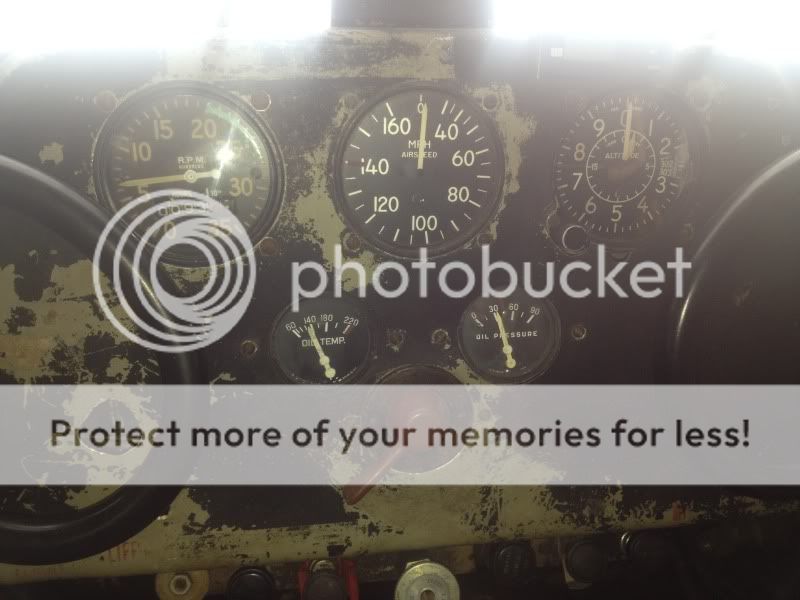

Put in a good days work on it saturday since the weather was nice, just need one more day to get the anual finished up and i will be set!

Good oil pressure still!

not the prettiest, but she's never let me down yet, or I her.

Howard Wilson

Line Up and Wait

OOPs, Hi VanDy, I thought he was talking to me......

Yup. They are good little planes. I was seriously looking at Piets until I ran into my 1st Parrakeet project. Howard

Yup. They are good little planes. I was seriously looking at Piets until I ran into my 1st Parrakeet project. Howard

yakdriver

Cleared for Takeoff

- Joined

- Aug 29, 2011

- Messages

- 1,200

- Location

- Twin Falls, Idaho

- Display Name

Display name:

yellow peril

Hi Don.... I am curious.. I have been running the electric trim set up on my 801 for 10 years or so..... Not a hint of problems and I use it on every flight....

What troubles are you referring to ?

Thanks in advance.

Ben.

The Ray Allen trim system has gotten a lot better in the last couple of years since they changed the relay. On the RV it is much easier to fine tune cruise trim with the manual set up and it is dirt simple and will work forever and eliminates complexity. We have several RVs and other homebuilts around here and I have flown almost all of them. The electric trim works pretty good on the slower Zenith and Kitfox types and I don't have a problem with them but the manual works better on the RVs. Almost every one of the electric trim airplanes around here has had a problem with the electric trim at one time or another mainly the old style relay or the servo. Don

Last edited:

VanDy

Cleared for Takeoff

OOPs, Hi VanDy, I thought he was talking to me......

Yup. They are good little planes. I was seriously looking at Piets until I ran into my 1st Parrakeet project. Howard

Had to go back and look at your parakeet, good looking project you have!

You sure have good taste in airplanes Howard

-VanDy

yakdriver

Cleared for Takeoff

- Joined

- Aug 29, 2011

- Messages

- 1,200

- Location

- Twin Falls, Idaho

- Display Name

Display name:

yellow peril

I like that T-cart. Good candidate for a complete restoration as it looks so original. Don

tmyers

En-Route

Love the fenders, that is a great touch. I still have some flat black spray paint at the hanger that would go well with that panel!!!

tmyers

En-Route

Howard, Your T Craft is equally gorgeous. Did you put a larger powerplant in it that required the mods to the cowl?

Howard Wilson

Line Up and Wait

Had to go back and look at your parakeet, good looking project you have!

You sure have good taste in airplanes Howard

-VanDy

Thanks VanDy. So do you;-)

The Ray Allen trim system has gotten a lot better in the last couple of years since they changed the relay. On the RV it is much easier to fine tune cruise trim with the manual set up and it is dirt simple and will work forever and eliminates complexity. We have several RVs and other homebuilts around here and I have flown almost all of them. The electric trim works pretty good on the slower Zenith and Kitfox types and I don't have a problem with them but the manual works better on the RVs. Almost every one of the electric trim airplanes around here has had a problem with the electric trim at one time or another mainly the old style relay or the servo. Don

Thanks for the reply......

I have heard the servos acted too fast for the RV's and other fast planes and the fix was to change the pivot points on the trim tab to alter the leverage..

:wink2:..

:wink2:..Howard Wilson

Line Up and Wait

Howard, Your T Craft is equally gorgeous. Did you put a larger powerplant in it that required the mods to the cowl?

Hi Tim,

Parts for the original Lycoming engines were getting very hard to find, and if you found them, very expensive. So I made the decision to convert it over to a Continental 65 which still has 'reasonable' parts availability. The planes came out of the factory with the option of three different engines, the Lyc., Cont., and the Franklin. The cowlings of course were all different.....Paperwork wise it's not a big deal. Tin beating is NOT my forte'. I've flown the 65hp Continental planes and 65 hp Lycs. The Continental powered planes are noticeably more peppy than the Lycs, imo. Howard

VanDy

Cleared for Takeoff

Love the fenders, that is a great touch. I still have some flat black spray paint at the hanger that would go well with that panel!!!

Thanks, but it'll do for now, i'm going to fly her all i can this summer until the Pietenpol is done, then its going to be a ground up restoration (close anyway) on the T-craft, just a couple of small mods in mind.

tmyers

En-Route

If I can help with anything let me know.

VanDy

Cleared for Takeoff

Better be careful, I just might take you up on that!

If I can help with anything let me know.

Geico266

Touchdown! Greaser!

Thanks for the reply......

I have heard the servos acted too fast for the RV's and other fast planes and the fix was to change the pivot points on the trim tab to alter the leverage..:wink2:..

I believe the rate is now adjustable.

During slow flight they are not fast enough.

I believe the rate is now adjustable.

During slow flight they are not fast enough.

Not a problem for me........... I am ALWAYS in slow flight...

Howard Wilson

Line Up and Wait

Ok,

Resurrecting this thread to update the 1936 Rose Parrakeet rebuild. She's all together and ready to fly. We've been taxi testing over the last couple of days and there is nothing left to do but............

Resurrecting this thread to update the 1936 Rose Parrakeet rebuild. She's all together and ready to fly. We've been taxi testing over the last couple of days and there is nothing left to do but............

Attachments

Ok,

Resurrecting this thread to update the 1936 Rose Parrakeet rebuild. She's all together and ready to fly. We've been taxi testing over the last couple of days and there is nothing left to do but............

Be careful........

Howard Wilson

Line Up and Wait

yakdriver

Cleared for Takeoff

- Joined

- Aug 29, 2011

- Messages

- 1,200

- Location

- Twin Falls, Idaho

- Display Name

Display name:

yellow peril

Ok,

Resurrecting this thread to update the 1936 Rose Parrakeet rebuild. She's all together and ready to fly. We've been taxi testing over the last couple of days and there is nothing left to do but............

Don't do high speed taxi's. Decide you are going to fly and just do it. Looks like a nice bird and it should fly great. Don

flyingriki

Ejection Handle Pulled

- Joined

- Nov 25, 2008

- Messages

- 910

- Display Name

Display name:

flyingriki

Never saw this thread before. I'm making that ugly experience of overhauling an engine turn into an even uglier headache of all new baffles and wiring and engine monitor with all sorts of inputs.....

I've been down for a LOT longer than I figured.

I've been down for a LOT longer than I figured.

Rotormouse

Rotormouse